Filling and sealing process for placing mounting plate in shell and only exposing contact pins

A technology for mounting boards and housings, which is applied in the fields of coating non-metallic protective layers, coatings, and printed circuit manufacturing. It can solve the problems of non-detachable modules and the inability to design the connection method of mounting boards and housing fasteners, and achieve easy operation. , high reliability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

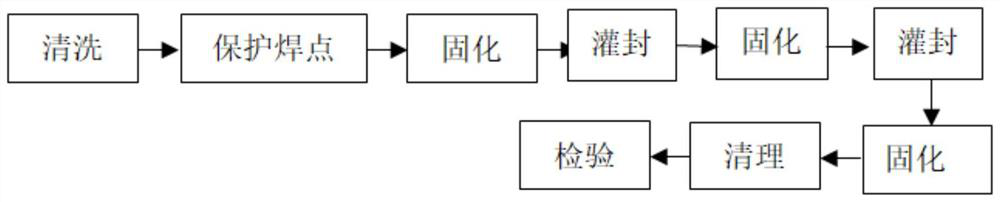

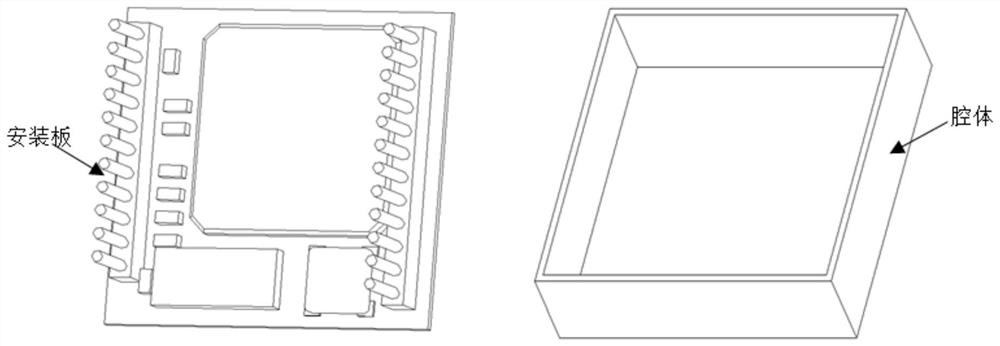

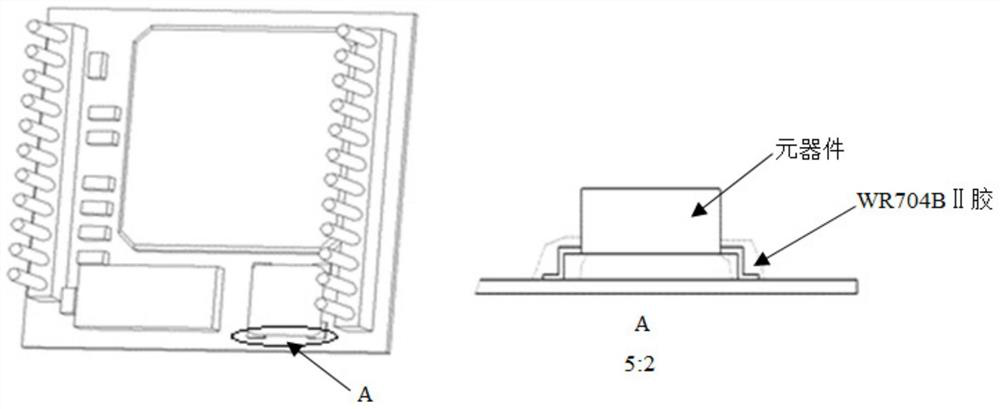

[0034] The potting process provides a method for protecting the solder joints of the device, without designing the mounting holes of the printed board, and directly potting the printed board in the shell with only connecting pins exposed. Including device solder joint protection process, mounting board and shell potting process. The specific process flow is:

[0035] like figure 1 As shown, the first step is to clean and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com