Metal net automatic welding device and welding method

An automatic welding and metal mesh technology, applied in the field of automation, can solve the problems of insufficient precision, high labor intensity, and inability to guarantee product quality, and achieve the effect of automatic welding and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

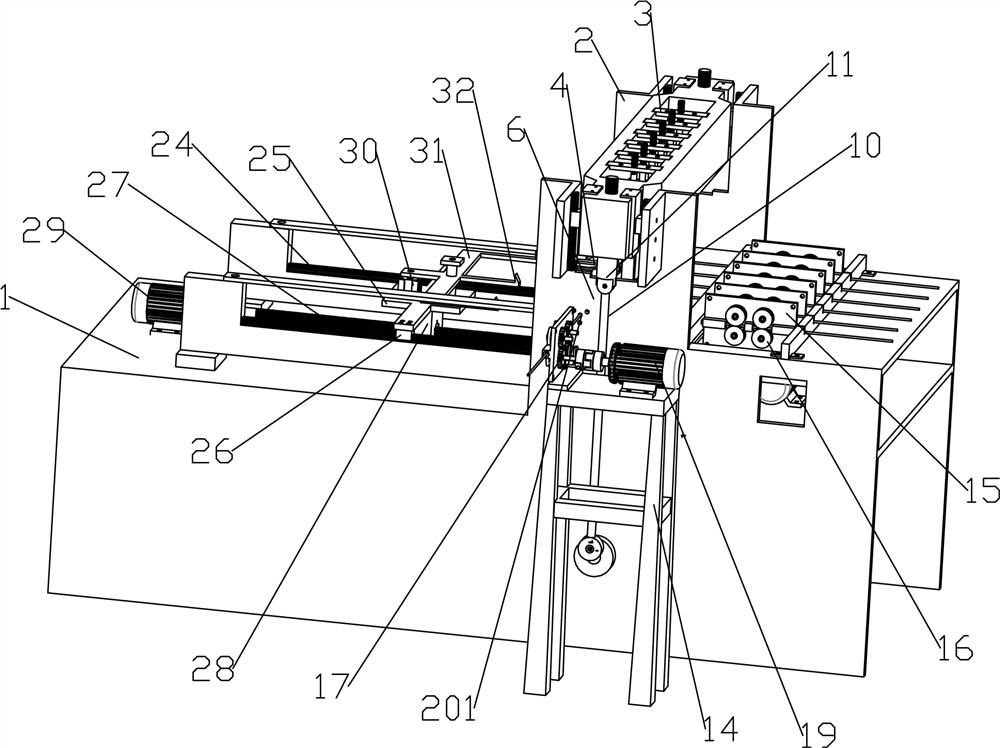

[0030] Such as figure 1 As shown, a metal mesh automatic welding device includes a machine platform 1, a support frame 2 is provided on both sides of the machine platform 1, vertical sliders 4 are provided at both ends of the welding frame 3, and a welding torch 5 is provided on the welding frame 3. In this embodiment, resistance welding is adopted, and the support frame 2 is provided with a vertical slide rail 6 cooperating with the vertical slider 4, and the welding frame 3 is driven up and down by an up and down drive mechanism, which can be optionally arranged on the support frame 2 The hydraulic bar or cylinder etc. are used to drive up and down.

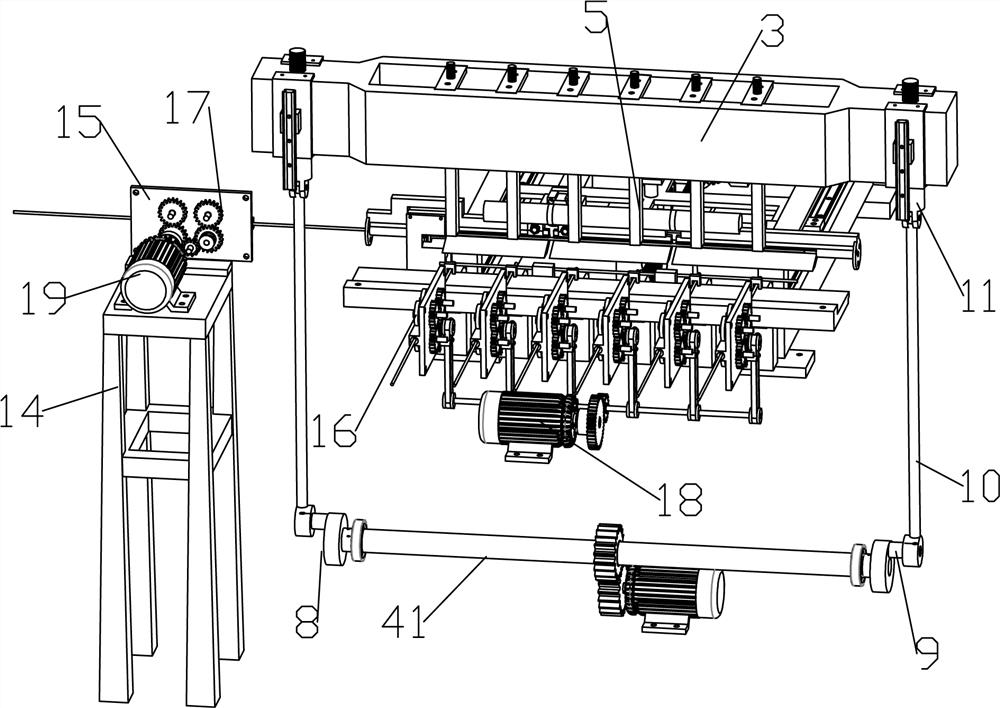

[0031] In this example, if figure 2 As shown, the up and down drive mechanism includes a drive shaft 41 arranged on the machine platform 1, the two ends of the drive shaft 41 are provided with a drive wheel 8, the eccentric position on the drive wheel 8 is provided with a connecting rod 9, and the connecting rod 9 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com