An armature iron core polishing device for electric tools

A technology of armature iron core and polishing device, which is used in grinding/polishing safety devices, devices for fixing grinding wheels, and manufacturing tools, etc. The effect of controlling the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

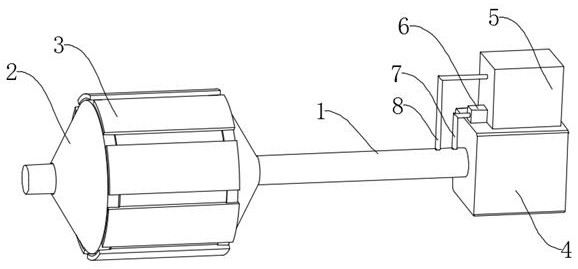

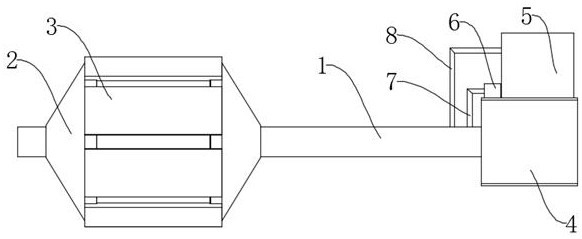

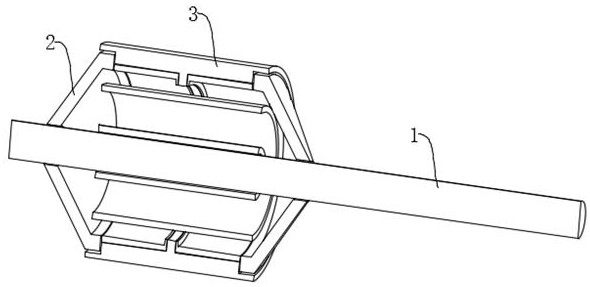

[0055] The present invention provides such as Figure 1-10 The shown armature iron core polishing device for electric tools comprises a transmission rod 1, the transmission rod 1 is provided with a fixed assembly 2, and the fixed assembly 2 is provided with a polishing assembly 3 for polishing the armature iron core, The end of the transmission rod 1 is provided with a driving component for driving the transmission rod 1 to rotate, and the driving component is provided with a medium adding component for adding cooling medium to the fixed component 2;

[0056] The fixing assembly 2 includes a casing 11 fixed at the outer ring of the transmission rod 1, one end of the casing 11 is fixed on the transmission rod 1 by screws, the casing 11 is a conical casing structure, and the casing 11 is provided with a Two groups, two groups of shells 11 are symmetrically distributed with respect to the polishing assembly 3;

[0057] The polishing assembly 3 includes a polishing and polishing ...

Embodiment 2

[0091] The present invention provides such as Figure 1-10The shown armature iron core polishing device for electric tools comprises a transmission rod 1, the transmission rod 1 is provided with a fixed assembly 2, and the fixed assembly 2 is provided with a polishing assembly 3 for polishing the armature iron core, The end of the transmission rod 1 is provided with a driving component for driving the transmission rod 1 to rotate, and the driving component is provided with a medium adding component for adding cooling medium to the fixed component 2;

[0092] The fixing assembly 2 includes a casing 11 fixed at the outer ring of the transmission rod 1, one end of the casing 11 is fixed on the transmission rod 1 by screws, the casing 11 is a conical casing structure, and the casing 11 is provided with a Two groups, the two groups of shells 11 are symmetrically distributed with respect to the polishing assembly 3;

[0093] The polishing assembly 3 includes a polishing and polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com