Modularized presser convenient to flexibly mount and working method thereof

A modular, press technology, applied in chemical instruments and methods, cleaning methods using liquids, presses, etc., can solve the problems of inability to wash the grid, hanging on the wall in the drainage section, affecting the pressing effect, etc. High maintenance cost, good support and limiting effect, and the effect of solving difficult cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

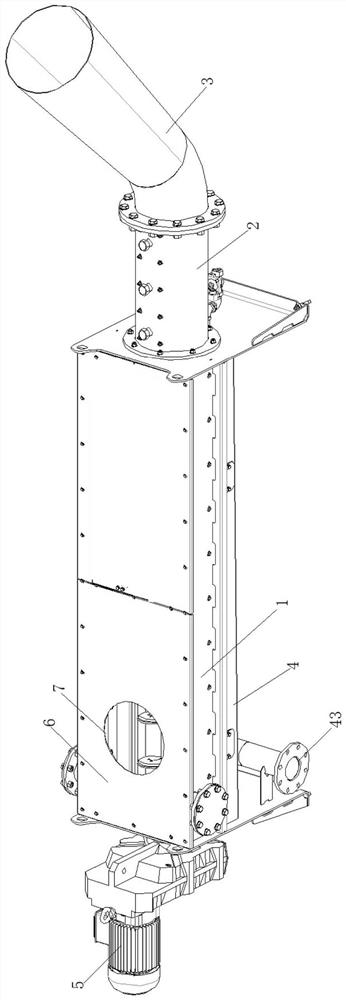

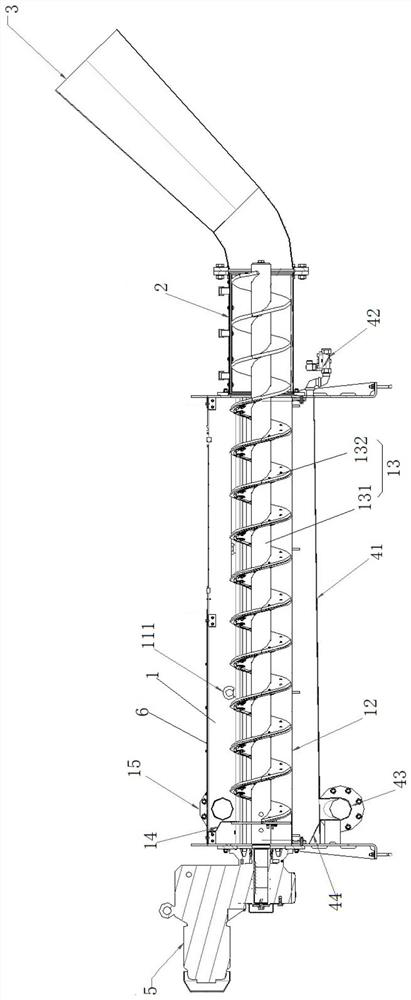

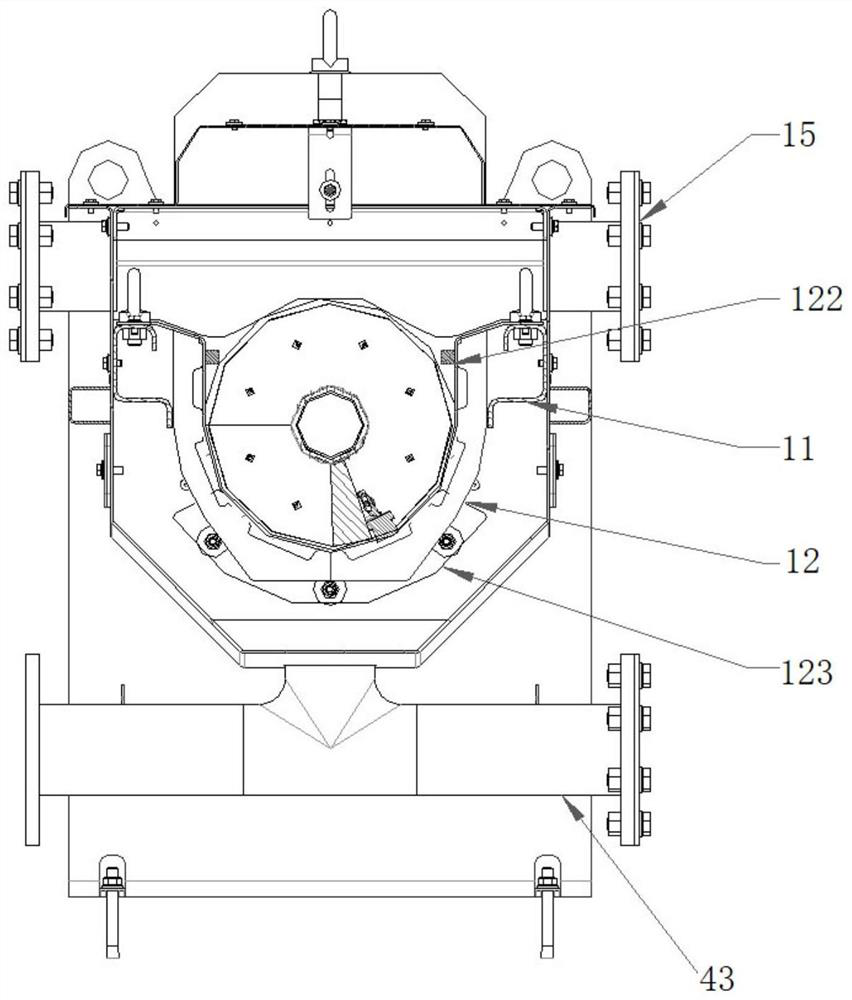

[0056] Such as Figures 1 to 4 as well as Figure 7 , Figure 8 A modular press that is convenient for flexible installation is shown, including: equipment main body section 1, pressing section 2, slag discharge pipe 3, drainage section 4 and pressing driving mechanism 5, above the equipment main section 1 there is an upper A cover 6, the upper cover 6 is provided with a gate slag inlet 7, the pressing section 2 is arranged at the output end of the equipment main section 1, and the slag discharge pipe 3 is arranged at the end of the pressing section 2 away from the equipment main section 1, In addition, both ends of the pressing section 2 are detachably connected to the equipment main section 1 and the slag discharge pipe 3, the drainage section 4 is arranged under the equipment main section 1, and the pressing driving mechanism 5 is arranged on the equipment main body Section 1 is far from the end of pressing section 2 and is connected with section 1 of the main body of the...

Embodiment 2

[0066] Such as Figures 3 to 9 The modular press shown is convenient for flexible installation, including a main body section 1, a pressing section 2, a slag discharge pipe 3, a drainage section 4 and a pressing driving mechanism 5, and an upper cover 6 is arranged above the main section 1 of the equipment, so that The upper cover 6 is provided with a gate slag inlet 7, the squeezing section 2 is set at the output end of the main body section 1 of the equipment, the slag discharge pipe 3 is set at the end of the squeezing section 2 away from the main section 1 of the equipment, and the squeezing The two ends of the section 2 are detachably connected to the main section 1 of the equipment and the slag discharge pipe 3, the drainage section 4 is set under the main section 1 of the equipment, and the pressing drive mechanism 5 is set on the main section 1 of the equipment away from the press. One end of the section 2 is connected with the main body section 1 of the equipment; it ...

Embodiment 3

[0079] Such as Figures 3 to 8 The modular press shown is convenient for flexible installation, including a main body section 1, a pressing section 2, a slag discharge pipe 3, a drainage section 4 and a pressing driving mechanism 5, and an upper cover 6 is arranged above the main section 1 of the equipment, so that The upper cover 6 is provided with a gate slag inlet 7, the squeezing section 2 is set at the output end of the main body section 1 of the equipment, the slag discharge pipe 3 is set at the end of the squeezing section 2 away from the main section 1 of the equipment, and the squeezing The two ends of the section 2 are detachably connected to the main section 1 of the equipment and the slag discharge pipe 3, the drainage section 4 is set under the main section 1 of the equipment, and the pressing drive mechanism 5 is set on the main section 1 of the equipment away from the press. One end of the section 2 is connected with the main body section 1 of the equipment; it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com