Carton sealing structure and carton sealing device for packaging carton in warehouse logistics

A warehousing logistics and box sealing technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of product falling and easy cracking, and achieve the advantages of not being easy to break, improving load-bearing capacity, and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

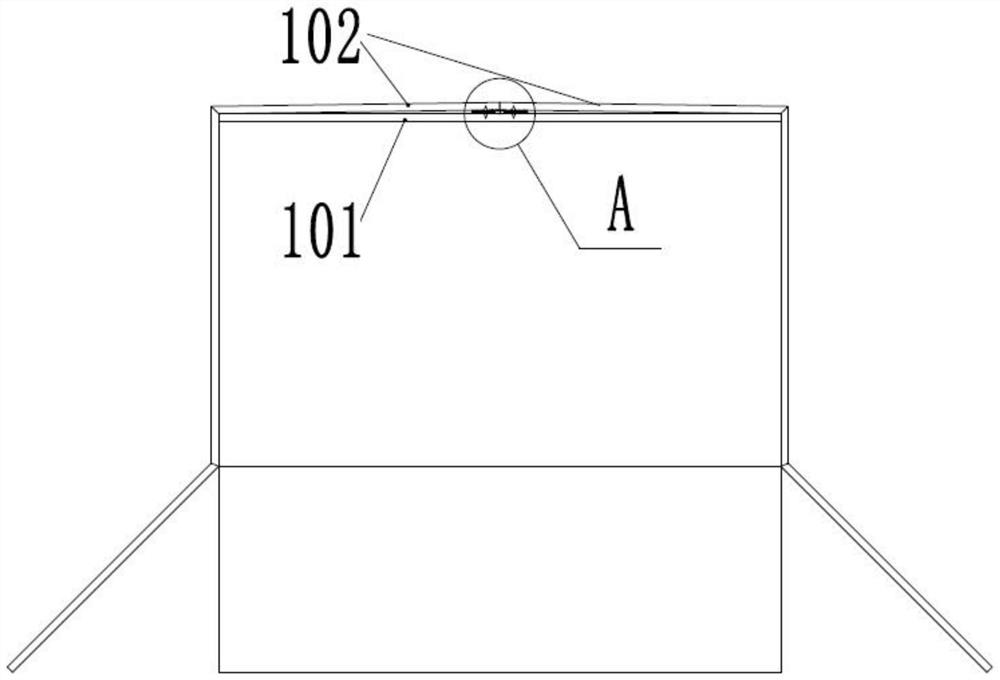

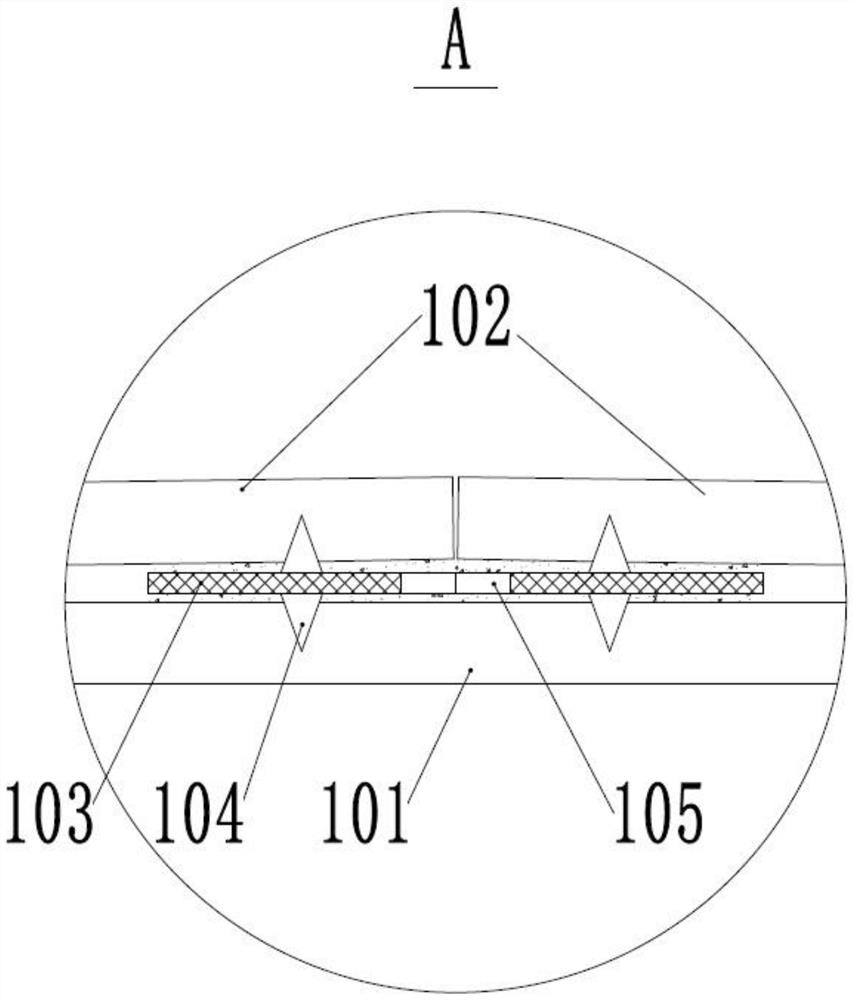

[0034] Improvements are made to the six-sided cuboid packaging box, especially the sealing structure at the bottom; in a specific embodiment, the embodiment of the present invention provides a sealing structure for packaging cartons in warehousing and logistics, please refer to Figure 1-Figure 3 ,include:

[0035] The first bottom plate 101 is a shorter plate, and the two first bottom plates 101 are located at the bottom of the wide sides of the six-sided box body and can be relatively inwardly bent;

[0036] The second bottom plate 102 is a longer plate, and the two second bottom plates 102 are located at the bottom of the long sides of the six-sided box body and can be bent and abutted relatively inward; and

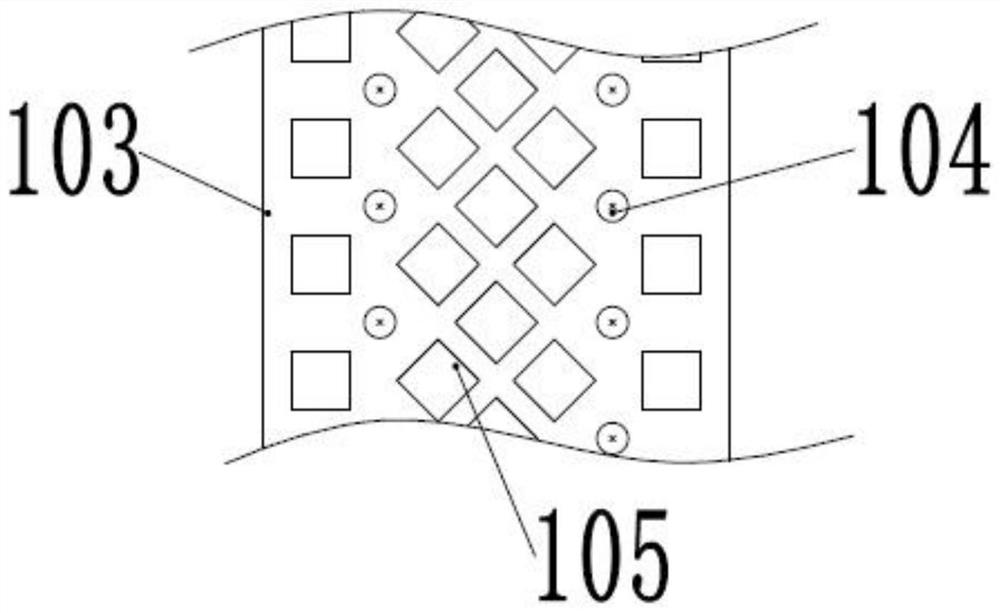

[0037] The reinforcing connecting belt 103 can be made of a material with a certain hardness, and its thickness is about 0.5mm. It has spikes 104 on both sides and sides along the length direction; wherein, when the two second bottom plates 102 are bent When resting ...

Embodiment 2

[0041] Based on the sealing structure of the first embodiment, the present invention also provides a sealing device for the sealing structure of the packaging carton in the above-mentioned warehousing logistics, please refer to Figure 4-Figure 8 ,include:

[0042]The workbench 1 is used to place the six-sided box upside down on it, and the two first bottom plates 101 are relatively inwardly bent first, so that the first bottom plate 101 is in contact with the upper plane of the workbench 1 to form a support. If the two There is a gap between the two first bottom plates 101, so at this time, cardboard of matching size can be filled and placed in the gap, that is, to ensure flatness, and then the two second bottom plates are relatively inwardly bent. 102, but not overlapped with the first base plate 101; the workbench 1 is moved and set along the extension direction of the joint of the two second base plates 102, and several workbenches 1 can be set to form a transmission circu...

Embodiment 3

[0047] This embodiment is further improved on the basis of the second embodiment, the difference is that, in order to pre-position the second bottom plate 102 before pressing, in this embodiment, optionally, both sides of the glue head 2 have The glue-coated limit groove 23 for limiting the seam edge of the second base plate 102 ensures that the width of the joint of the two second base plates 102 is about 1 cm, and the limit groove is used for presetting the second base plate 102 before pressing. position, preventing the second bottom plate 102 from contacting the first bottom plate 101 prematurely.

[0048] Further, it also includes: a pre-positioning groove 11 arranged above the workbench 1 along the extension direction of the joint of the second bottom plate 102 to pre-position the two second bottom plates 102 into a figure-eight shape, and the pre-positioning groove 11 is convenient for operation After the box is buckled upside down on the workbench 1, when the first bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com