A cooler for coal mining equipment

A cooler and equipment technology, which is applied in mechanical equipment, gear lubrication/cooling, earthwork drilling and mining, etc. It can solve the problems of low heat conduction efficiency, wear of transmission gear shaft, limited cooling effect of internal gear shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to illustrate the structural features and effects of the present invention more clearly, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

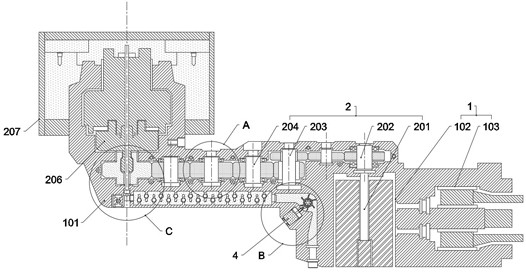

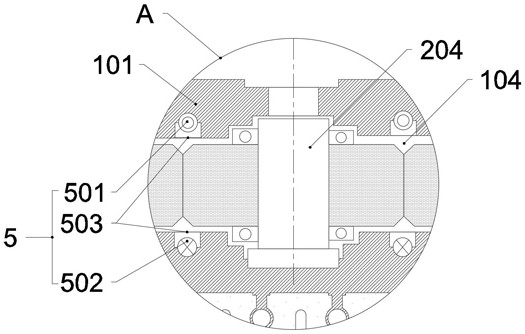

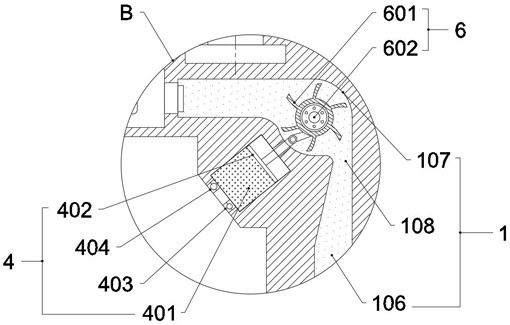

[0046] see Figure 1-Figure 7, a cooler for coal mining equipment in an embodiment of the present invention includes a rocker arm member 1, the rocker arm member 1 includes a rocker arm housing 101, a gear cavity 104 and a heat conduction cavity 105, the rocker arm housing 101 A number of gear cavities 104 are arranged in the inner array, and the several gear cavities 104 are connected. A heat conduction cavity 105 is also arranged on one side of the rocker shell 101. The drive assembly 2 includes a main motor 201, a secondary pinion 202 and a number of transmission gears 204. The main motor 201 is arranged at one end of the rocker arm housing 101, and the main motor 201 is connected to the rocker arm through the secondary pinion 202. The casings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com