Automatic cleaning and spraying device for assembled pier column outer mold

An automatic cleaning and spraying device technology, which is applied in the direction of spraying devices, grinding drive devices, spray booths, etc., can solve the problems of unqualified appearance quality of prefabricated pier columns, unqualified cleaning quality of prefabricated pier column external molds, etc., to achieve convenient removal Model, avoid the effect of eccentric movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An automatic cleaning and spraying device for the outer mold of an assembled pier column, including a pillar system, a standard section movable grinding device and a bottom special-shaped grinding device;

[0039] The pillar system includes a base, a pillar, a pillar rotation drive device and a traction device. There are multiple sets of hydraulic clamping ends on the outer wall of the base, and the base is connected to the fixed pedestal through the hydraulic clamping ends; the pillar rotation drive device is arranged in the base, Including the driving motor, the lower end of the pillar is connected to the rotation driving device, which can drive the pillar to rotate along its central axis, and then drive the standard section movable grinding device and the bottom special-shaped grinding device to rotate along the central axis of the pillar, so that the outer mold realizes ring Grind toward the week.

[0040]The traction device is connected to the upper end of the pill...

Embodiment 2

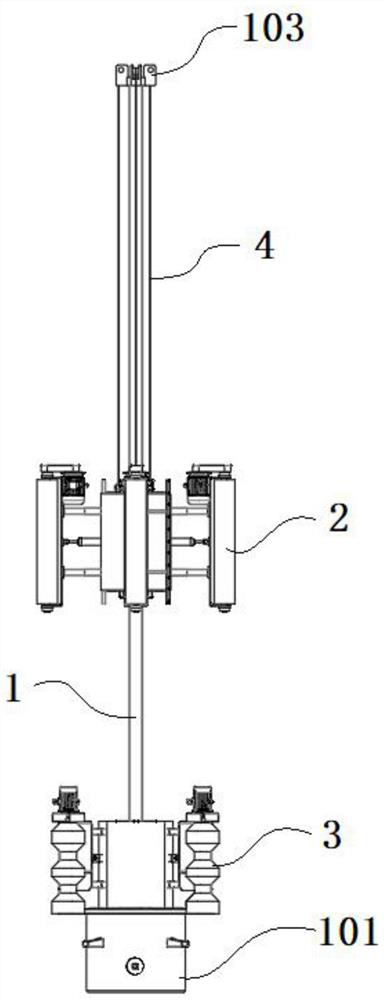

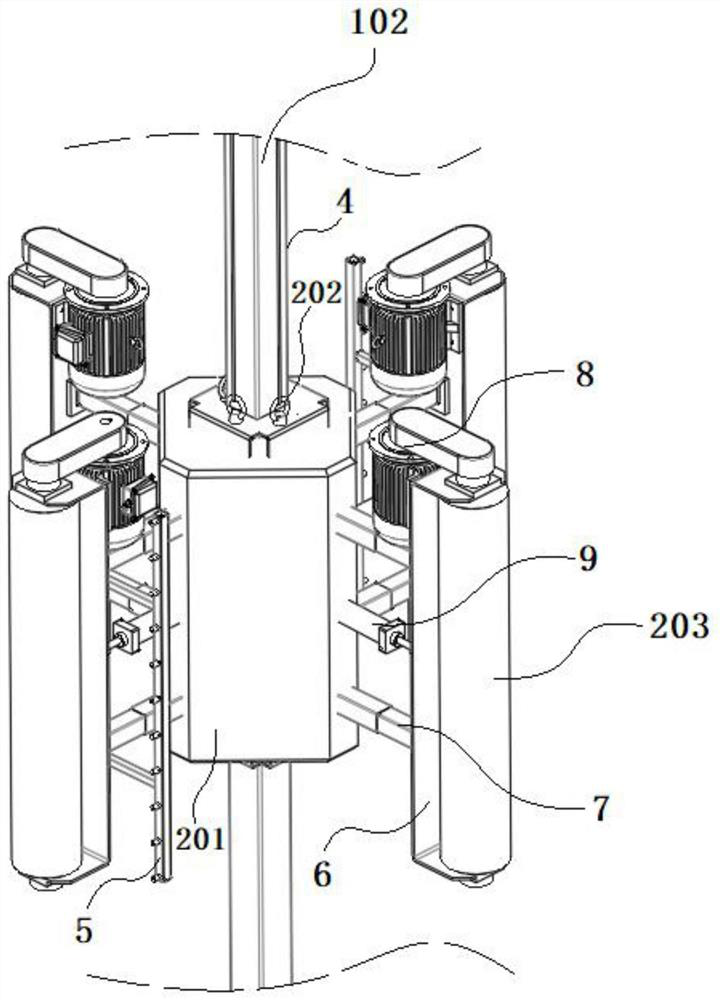

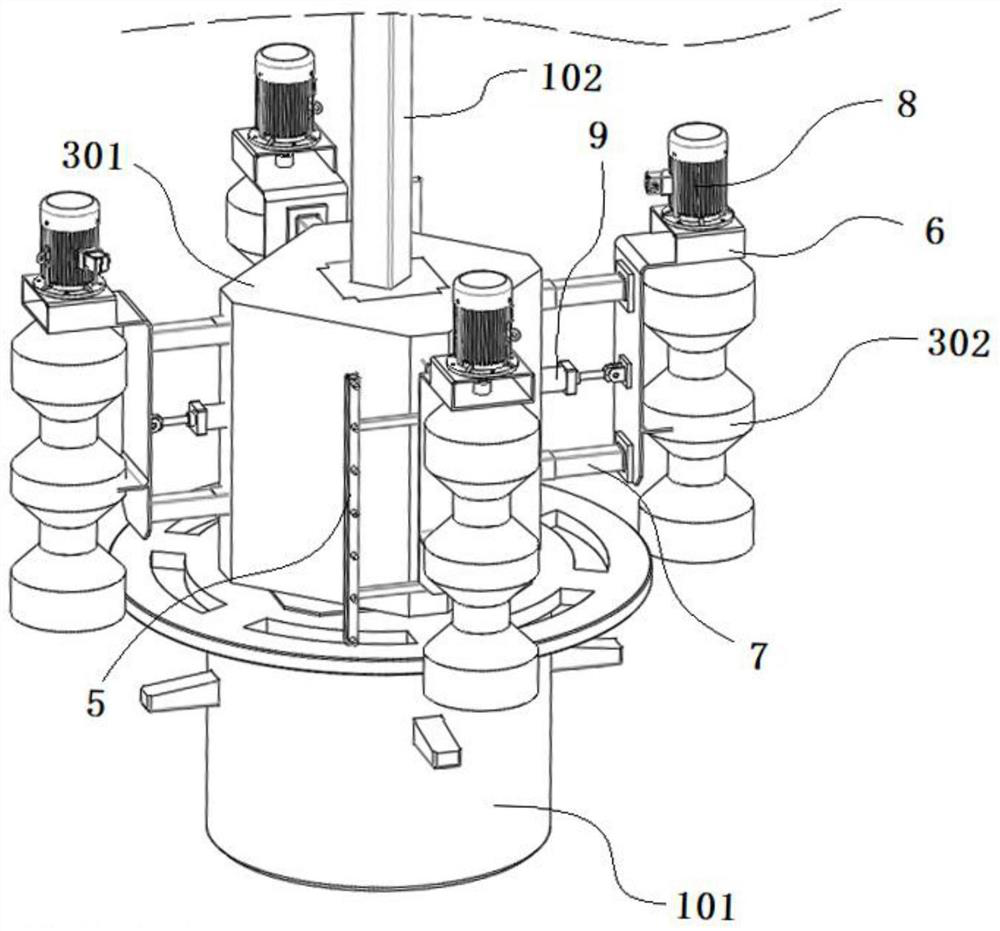

[0044] see figure 1 , an assembly pier column outer mold automatic cleaning spraying device, including a pillar system 1, a standard section movable grinding device 2 and a bottom special-shaped grinding device 3;

[0045] The pillar system 1 comprises a base 101, a pillar 102, a pillar rotation driving device and a traction device 103. The pillar rotation driving device is arranged in the base 101 and includes a drive motor. The lower end of the pillar 102 is connected to the pillar rotation driving device. The pillar rotation driving device can Drive the pillar 102 to rotate along its central axis and then drive the standard joint movable grinding device 2 and the bottom special-shaped grinding device 3 to rotate along the central axis of the pillar 102, so that the outer mold can be polished in a circular direction.

[0046] The traction device 103 is connected to the upper end of the pillar 102, the standard section mobile grinding device 2 is movable on the pillar 102, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com