Feeding mechanism for foaming machine and use method of feeding mechanism

A technology of feeding mechanism and foaming machine, applied in plastic recycling, ceramic molding machine, recycling technology, etc., can solve the problems of waste of cement resources, physical impact of operators, etc., to avoid waste of cement, avoid waste, and promote Shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

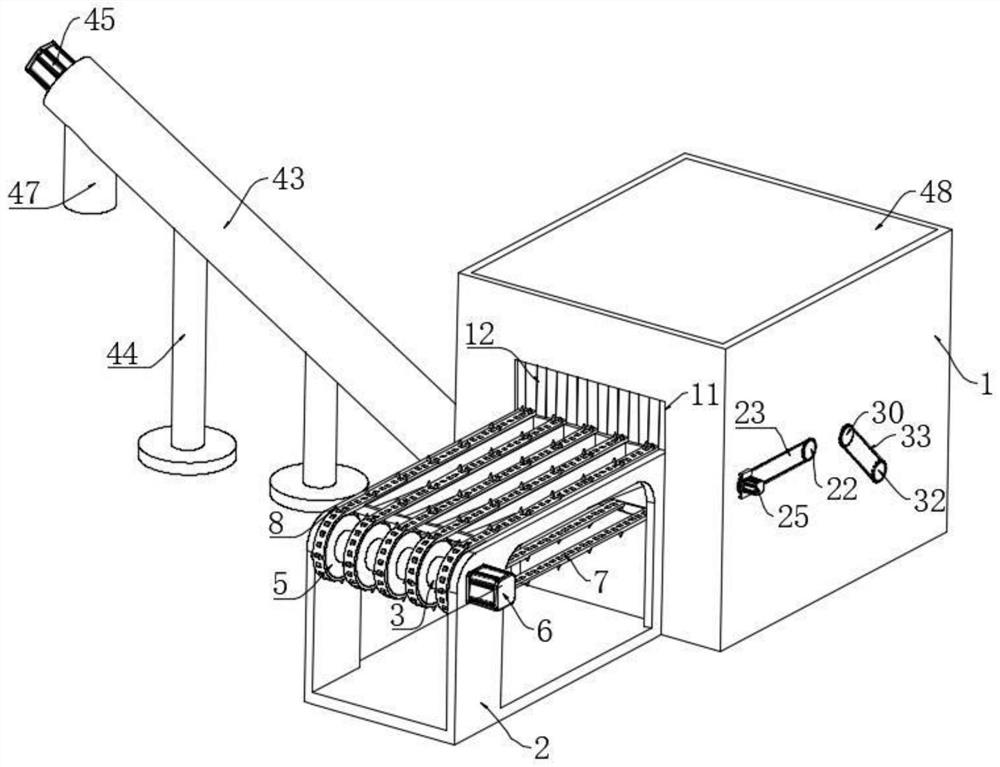

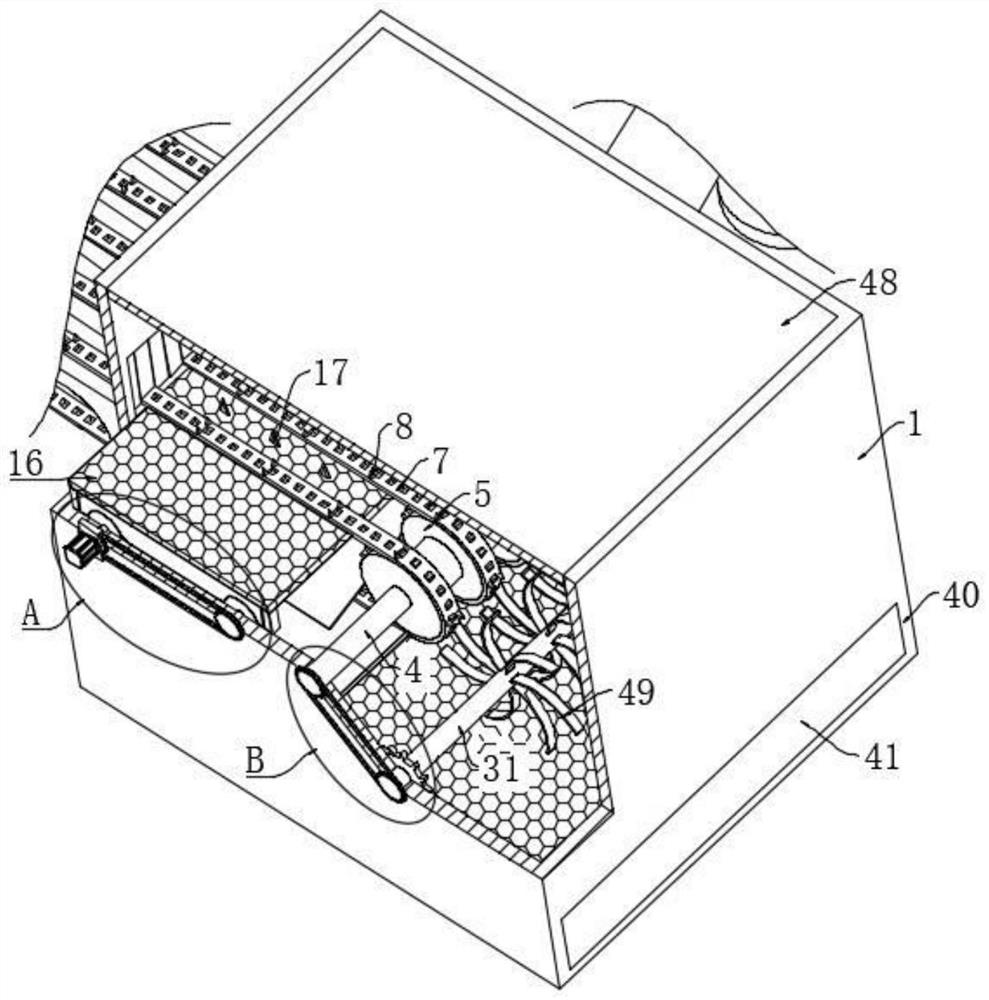

[0055] As an embodiment of the present invention, the dust-proof bag removing device includes a first rotating shaft 3 , a second rotating shaft 4 , a first motor 6 and a screen plate 16 . , the two ends of the second rotating shaft 4 are rotatably mounted on the inner wall of the frame body 1, the outer rings of the first rotating shaft 3 and the second rotating shaft 4 are both fixed with a gear plate 5 in a linear array, and the two gear plates 5 are aligned between them. A conveyor belt 7 is connected in a common drive. A number of rubber protrusions 8 are fixed in an array on the outer side walls of all conveyor belts 7. The first motor 6 is fixedly installed on one side wall of the installation table 2 by screws. The output shaft of the first motor 6 The sieve plate 16 is slidably installed on the inner wall of the frame body 1 after passing through the side wall of the installation table 2 and is fixedly connected with the first rotating shaft 3. The top of the sieve pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com