Full-automatic intelligent opening circling all-in-one machine

A fully automatic, all-in-one machine technology, applied in paper/cardboard containers, packaging, papermaking, etc., to achieve the effects of improving production efficiency, reducing personnel input, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

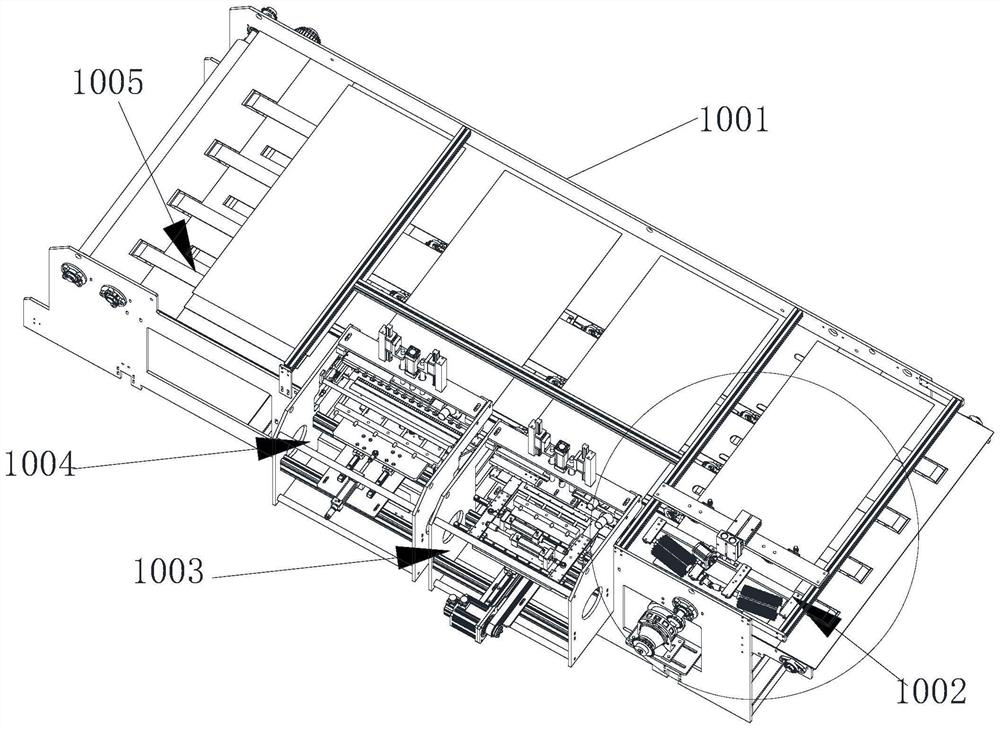

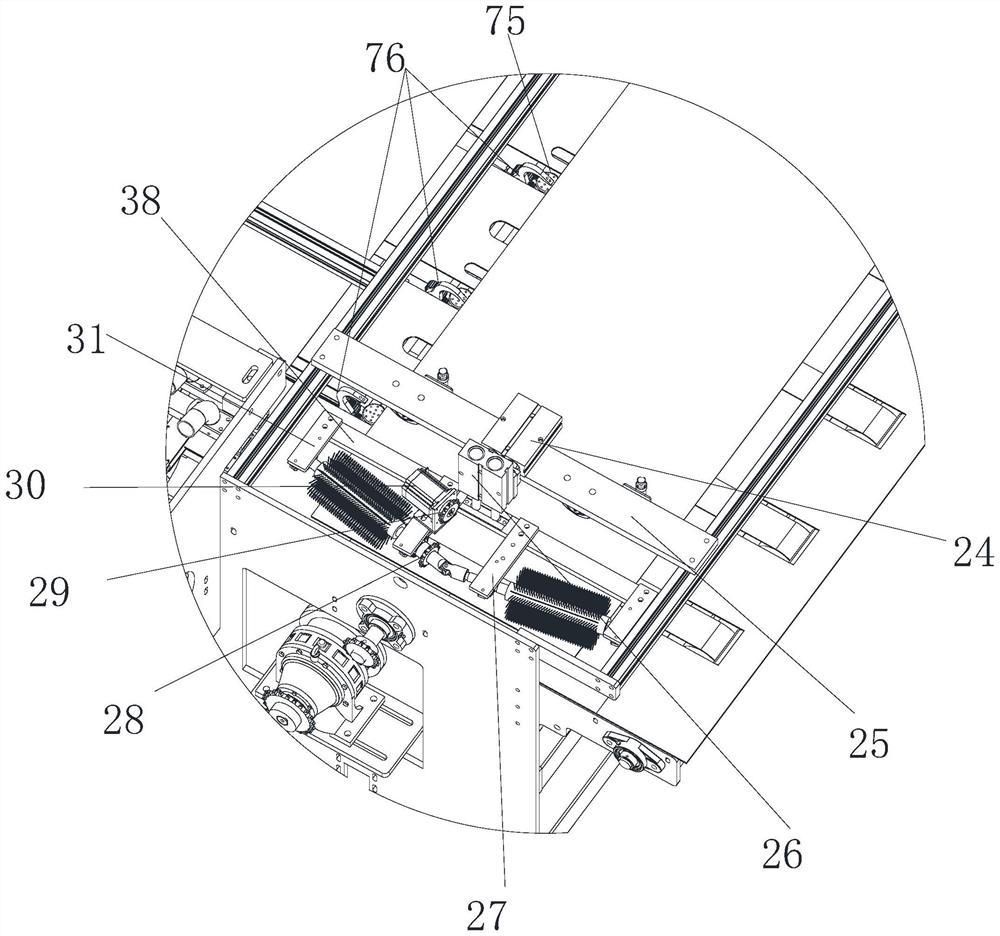

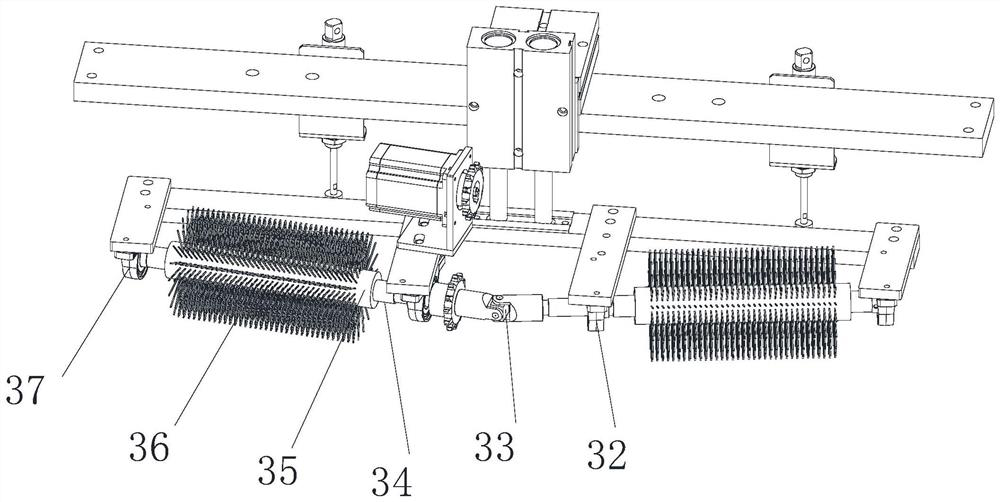

[0034] like figure 1As shown in the figure, the present invention discloses a fully automatic intelligent ring mouth integrated machine, including a frame and processing materials. The processing materials include a valve mouth or a woven bag, and the valve mouth or the woven bag has an outer bag and an inner bag. The inner bag generally refers to Inner film, description: The edge of the inner bag exceeds the mouth of the woven bag (outer bag) by a distance, generally 4-7cm. The frame is equipped with a processing and conveying platform 1001, a bag mouth leveling mechanism 1002, an outer bag and an inner bag. The first processing station 1003 of the bag mouth for flushing the bag mouth and the second processing station 1004 for the bag mouth to be folded and ironed after the first processing station is arranged;

The bag mouth leveling mechanism 1001 , the first bag mouth processing station 1002 and the bag mouth second processing station 1003 are sequentially arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com