Automatic cloth deviation rectifying device of printing machine

An automatic deviation correction device and printing machine technology, which is applied in the field of fabric processing, can solve problems such as poor deviation correction effect and waste of manpower, and achieve the effects of improving printing quality, reducing working strength and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

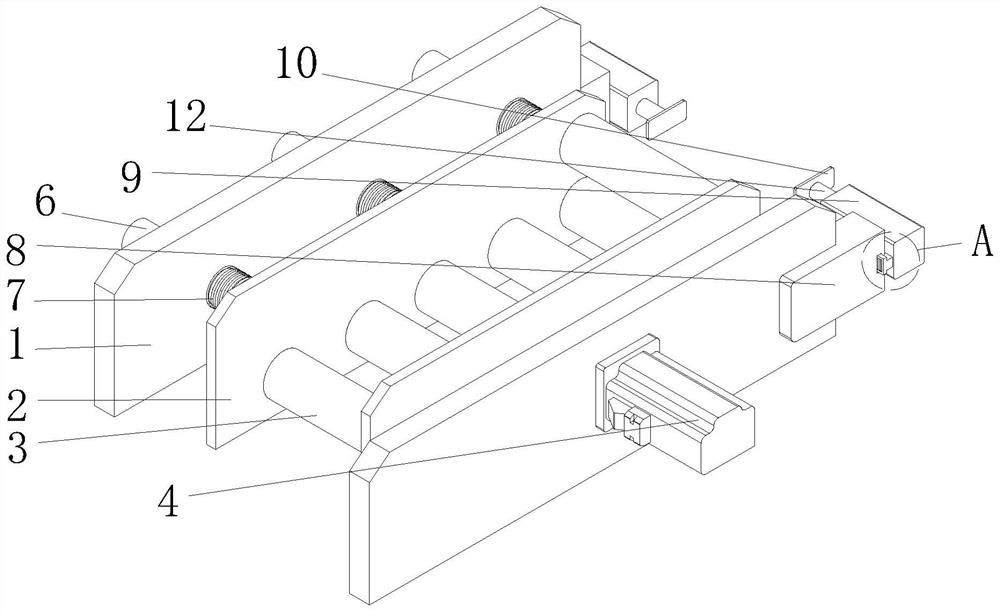

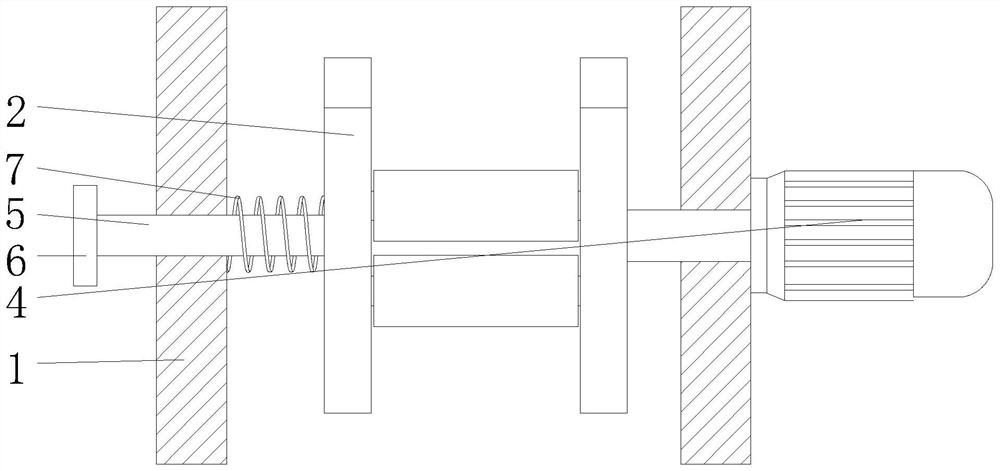

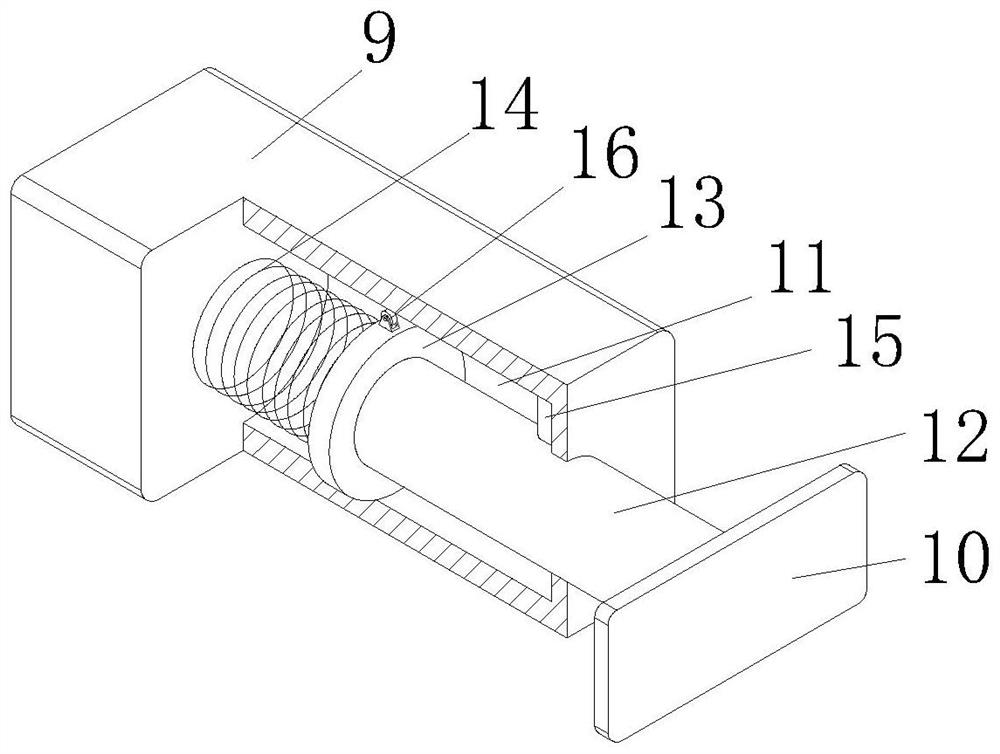

[0028] Example: an automatic correction device for fabrics of a printing machine, please refer to Figure 1-2 , including two mounting plates 1, two conveying plates 2 are arranged between the two mounting plates 1, and several conveying rollers 3 arranged in parallel and horizontally are rotatably connected between the two conveying plates 2. At the feeding port of the printing machine, the fabric is transported into the printing machine by the conveying roller 3.

[0029] Further, an electric push rod 4 is fixedly connected to the right side surface of the right mounting plate 1, and the telescopic rod of the electric push rod 4 slides through the right mounting plate 1 and is finally fixedly connected to the conveying plate 2, and the left conveying plate The left side surface of 2 is fixedly connected with a mounting slide bar 5, one end of the mounting slide bar 5 away from the conveying plate 2 slides through the left side mounting plate 1, and one end of the mounting sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com