Water quenching car and control method thereof

A technology of water quenching car and control method, which is applied in the field of coking, and can solve the problems of easy movement of the crank linkage mechanism, affecting production, easy air leakage and pressure relief, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

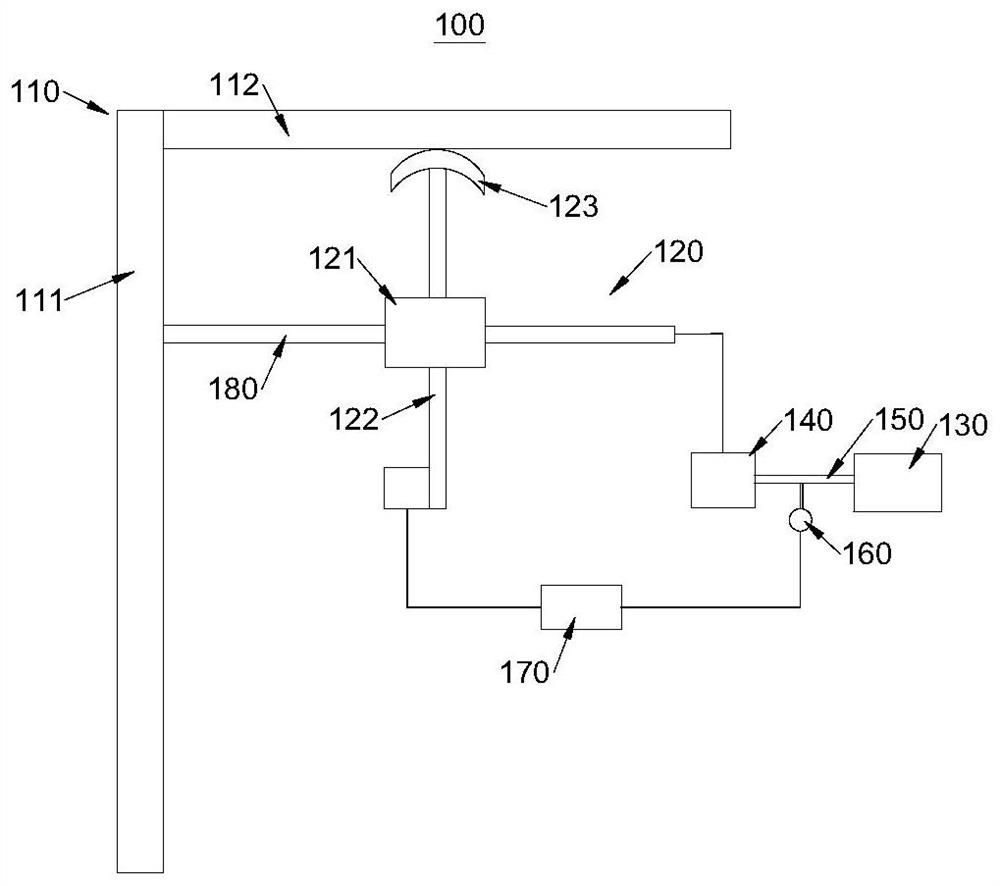

[0054] Please refer to figure 1 , this embodiment provides a water quenching vehicle 100, the water quenching vehicle 100 includes a compartment 110, an abnormal opening device 120, an air compressor 130, an opening and closing cylinder 140 and a controller 170, and the compartment 110 includes interconnected compartments The door 111 and the compartment wall 112 ; the abnormal opening prevention device 120 includes a connecting plate 121 , an electro-hydraulic push rod 122 and a locking frame 123 .

[0055] Specifically, the compartment door 111 is provided with a crank connecting rod 180 , the opening and closing cylinder 140 communicates with the air compressor 130 , and the opening and closing cylinder 140 is used to drive the crank connecting rod 180 to drive the compartment door 111 to open or close.

[0056] The connecting plate 121 can be a heat-resistant cast iron plate. The connecting plate 121 can be a rectangular structure with a size of 300mm*400mm. The connecting...

no. 2 example

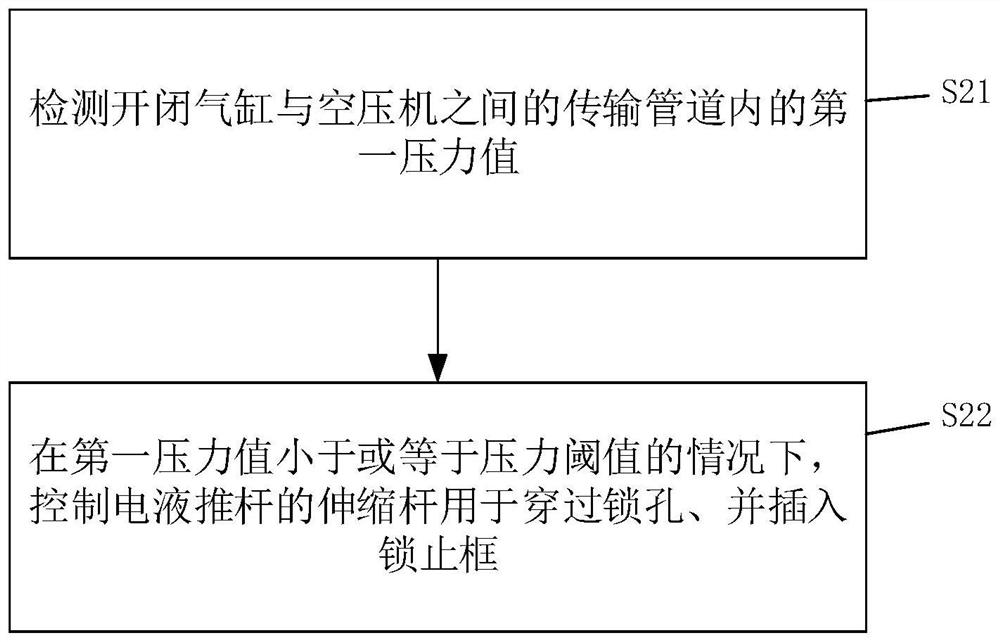

[0072] see figure 2 , the present embodiment provides a control method of the water quenching vehicle 100, the control method of the water quenching vehicle 100 is applied to the water quenching vehicle 100 of the aforementioned embodiment, and the control method of the water quenching vehicle 100 includes the following steps:

[0073] S21: Detect the first pressure value in the transmission pipeline 150 between the opening and closing cylinder 140 and the air compressor 130 .

[0074] Wherein, the first pressure value is detected by the electric contact pressure gauge 160 installed on the transmission pipeline 150 between the opening and closing cylinder 140 and the air compressor 130 .

[0075] S22: When the first pressure value is less than or equal to the pressure threshold, control the telescopic rod of the electro-hydraulic push rod 122 to pass through the lock hole and insert into the locking frame 123 .

[0076] In this way, when the pressure in the transmission pipe...

no. 3 example

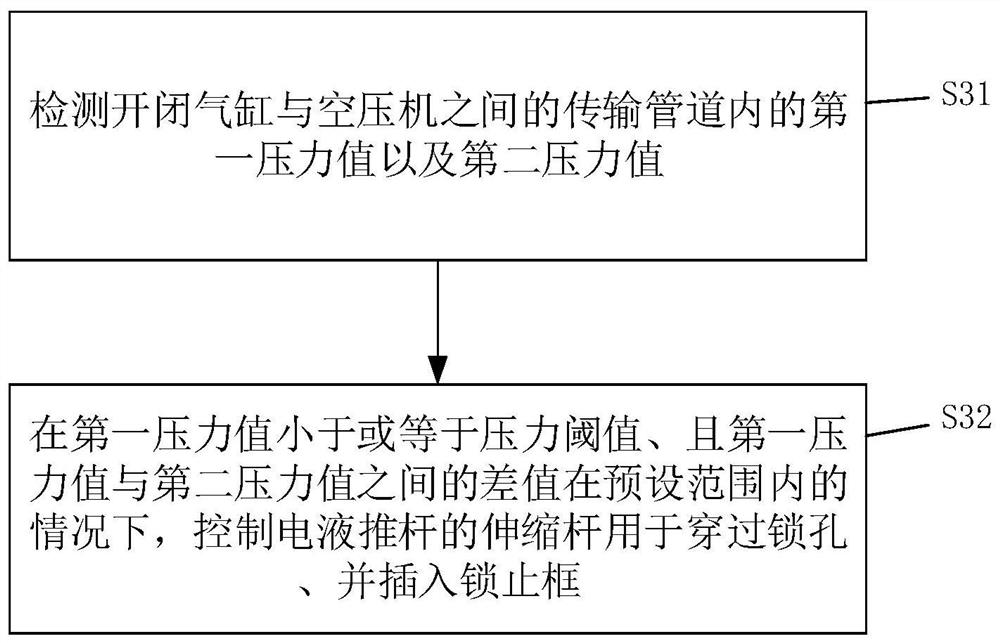

[0078] see image 3 , the present embodiment provides a control method of the water quenching vehicle 100, the control method of the water quenching vehicle 100 is applied to the water quenching vehicle 100 of the aforementioned embodiment, and the control method of the water quenching vehicle 100 includes the following steps:

[0079] S31: Detect the first pressure value and the second pressure value in the transmission pipeline 150 between the opening and closing cylinder 140 and the air compressor 130 .

[0080] Wherein, the first pressure value is detected by the electric contact pressure gauge 160 installed on the transmission pipeline 150 between the opening and closing cylinder 140 and the air compressor 130 .

[0081] One end of the branch pipe is connected to the transmission pipeline 150 , and the other end of the branch pipe extends to the operating room. The spring tube pressure gauge is installed at the other end of the branch pipe. The spring tube pressure gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com