Gypsum crushing and falling-off equipment for orthopedics department

A gypsum and equipment technology, applied in the field of gypsum crushing and falling off equipment, can solve the problems of low demolition efficiency and potential safety hazards, and achieve the effect of conveniently crushing gypsum and avoiding abnormal opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

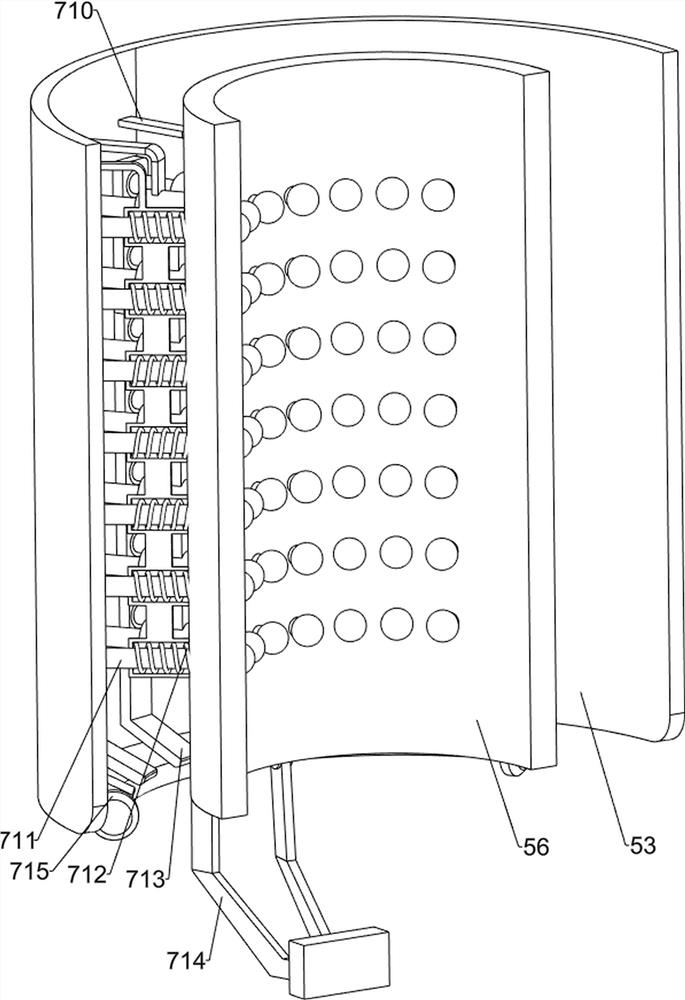

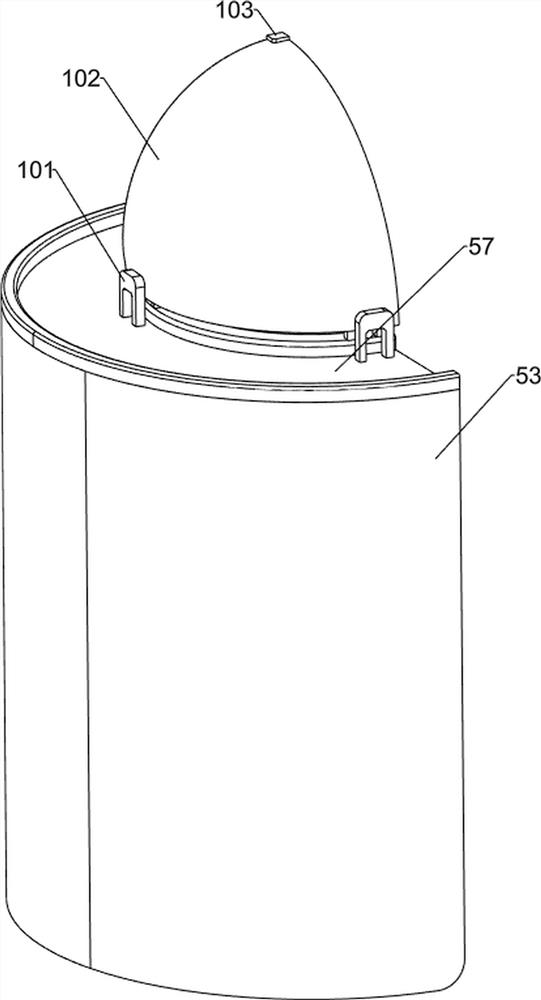

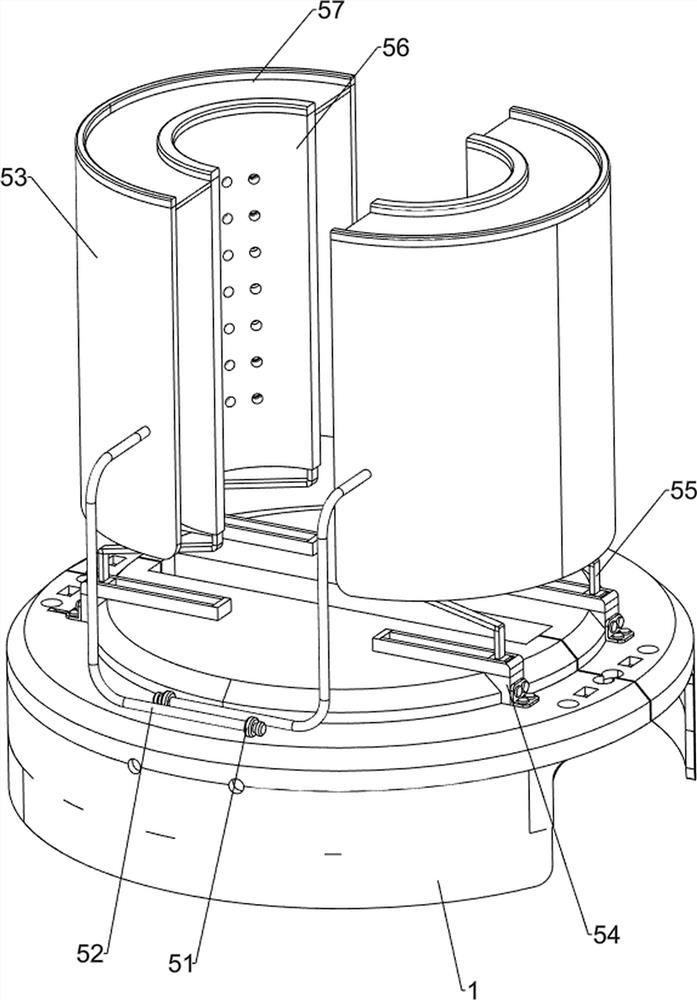

[0030] A kind of orthopedic gypsum crushing and falling off equipment, such as Figure 1-12 As shown, it includes a base 1, a foot frame 2, a pedal 3, a first spring 4, a fixed assembly 5, a locking assembly 6, a striking assembly 7 and a moving assembly 8. The top of the base 1 is provided with a foot frame 2, and the foot A pedal 3 is slidingly provided in the frame 2, and two rows of first springs 4 are connected between the pedal 3 and the foot frame 2. The base 1 is provided with a fixing component 5, and the fixing component 5 is provided with a locking component 6. The base 1 is provided with striking assembly 7, and base 1 is provided with moving assembly 8.

[0031] When using the device, the staff moves the device to a suitable position through the moving assembly 8, and then the patient puts the foot on the pedal 3, and under the action of gravity, the pedal 3 slides down the first spring 4 in the foot frame 2 Deformation occurs, and after putting it in place, fix ...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 and Figure 10 As shown, it also includes a pulling assembly 9, and the pulling assembly 9 includes a helical sleeve 92, a pulling frame 93, a straight rod 94 and a handle 95, and the right part of the rotating rod 84 is provided with a thread groove 91, and the rotating rod 84 is equipped with a screw groove. Be provided with spiral sleeve 92, be provided with pull frame 93 between two spiral sleeves 92, pull frame 93 right parts are provided with inline bar 94 symmetrically front and back, be provided with handle 95 between two inline bar 94 right parts.

[0042] When using the device, the staff pulls the handle 95 to move to the right, and the handle 95 moves to the right to drive the pull frame 93 to move to the right through the straight rod 94, and the pull frame 93 moves to the right to drive the spiral sleeve 92 to move to the right, and the screw sleeve 92 moves to the right. Under the action of 91, the spiral sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com