Brushless doubly-fed motor speed regulation system based on matrix converter and sliding mode control method

A technology of matrix converter and doubly-fed motor, applied in the direction of electronically commutated motor control, motor generator control, synchronous generator control, etc. Two-way flow and other issues, to achieve the effect of small parameter dependence, ensure static performance, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Detailed ways

[0039] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

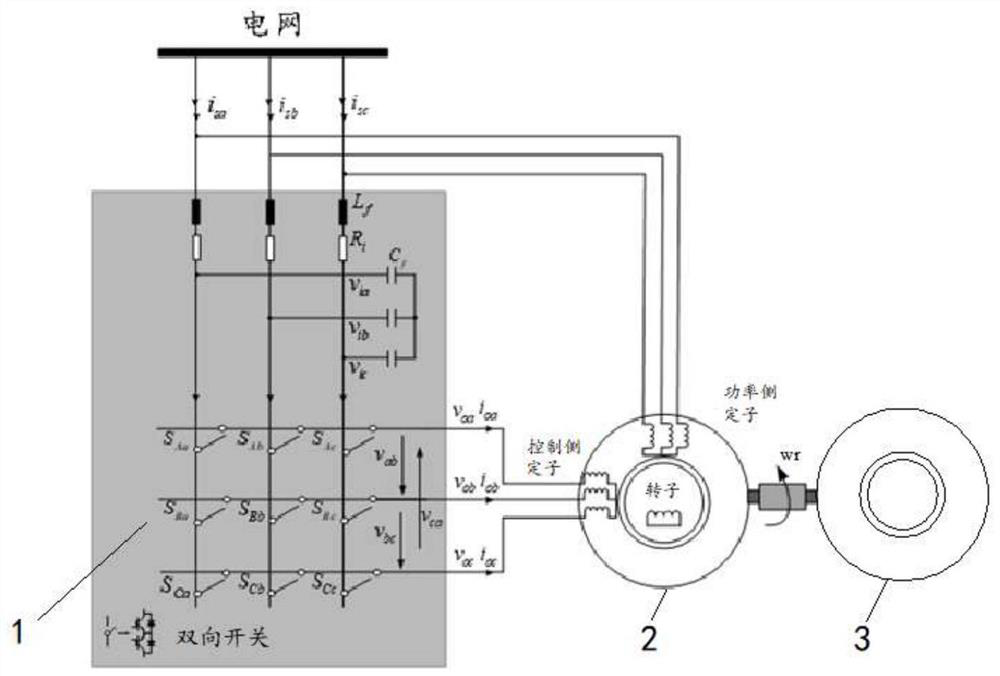

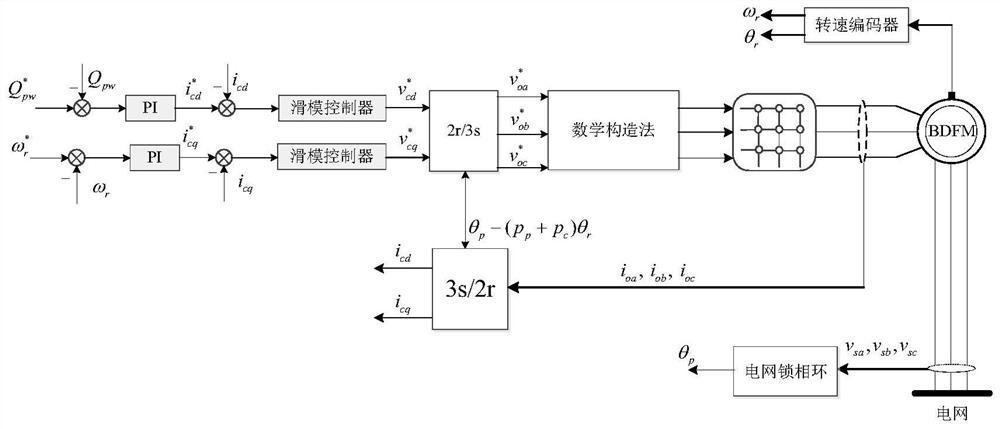

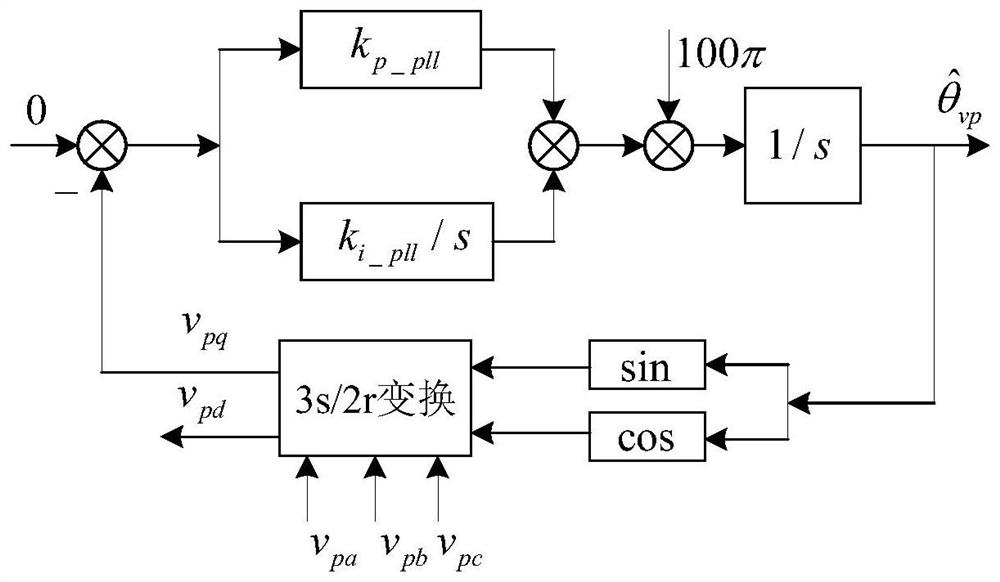

[0040] figure 1 Shown is a schematic diagram of the overall scheme of the matrix converter-brushless doubly-fed induction motor drive system of the present embodiment, which mainly includes a matrix converter 1, a brushless doubly-fed induction motor 2 and a squirrel-cage induction motor 3. The power-side stator winding "PW" of the brushless doubly-fed induction motor 2 is directly connected to the power grid, while the control-side stator winding "CW" is connected to the output end of the power converter, and the input end of the power converter is connected to the power grid through the input filter. online. The squirrel-cage induction motor 3 is coaxially connected to the brushless doubly-fed induction motor 2 for providing load torque. Using current and voltage sensors to measure the voltage and current signals of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com