Rotary pesticide dispersing device for forestry insect pests

A pest and forestry technology, applied in the field of rotary powder medicine device, can solve the problems of forestry resource quality decline, expenditure, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

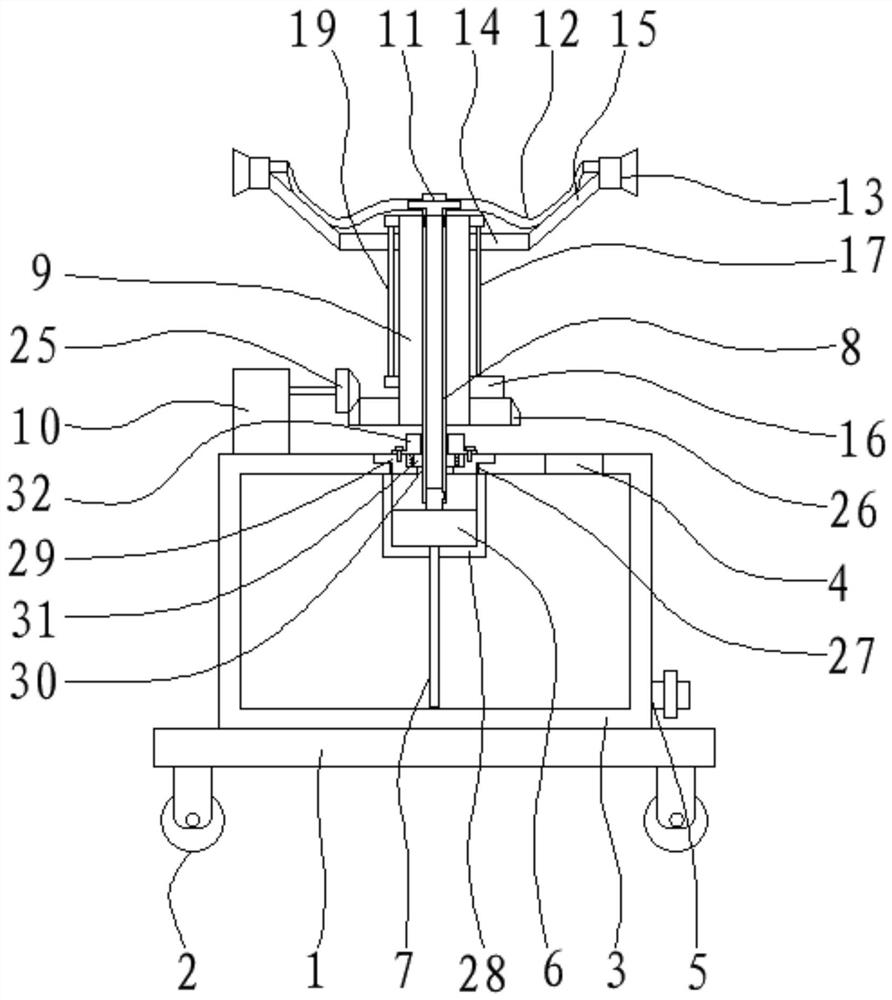

Embodiment 1

[0033] as Figure 1As shown, the present embodiment includes a base 1, the bottom of the base 1 is provided with a moving wheel 2, in order to facilitate the movement of the base 1, a pushrod may be provided at one end of the base 1 to achieve a manual push of the base 1, and may also be provided on the side wall of the base 1 to provide a hook, connected with a tractor, etc., so as to achieve the movement of the base 1, to achieve the movement of the entire device; The base 1 is fixed on the storage tank 3, the storage tank 3 is provided with an inlet port 4 and an outlet port 5, the inlet port 4 is located at the top of the storage tank 3, the outlet port 5 is provided at the bottom of the side wall of the storage tank 3, and the outlet port 5 is provided with a valve, the top inner wall of the storage tank 3 is fixed on the spray pump 6, the input end of the spray pump 6 is connected to the bottom of the inner cavity of the storage tank 3 through the input tube 7, the output end...

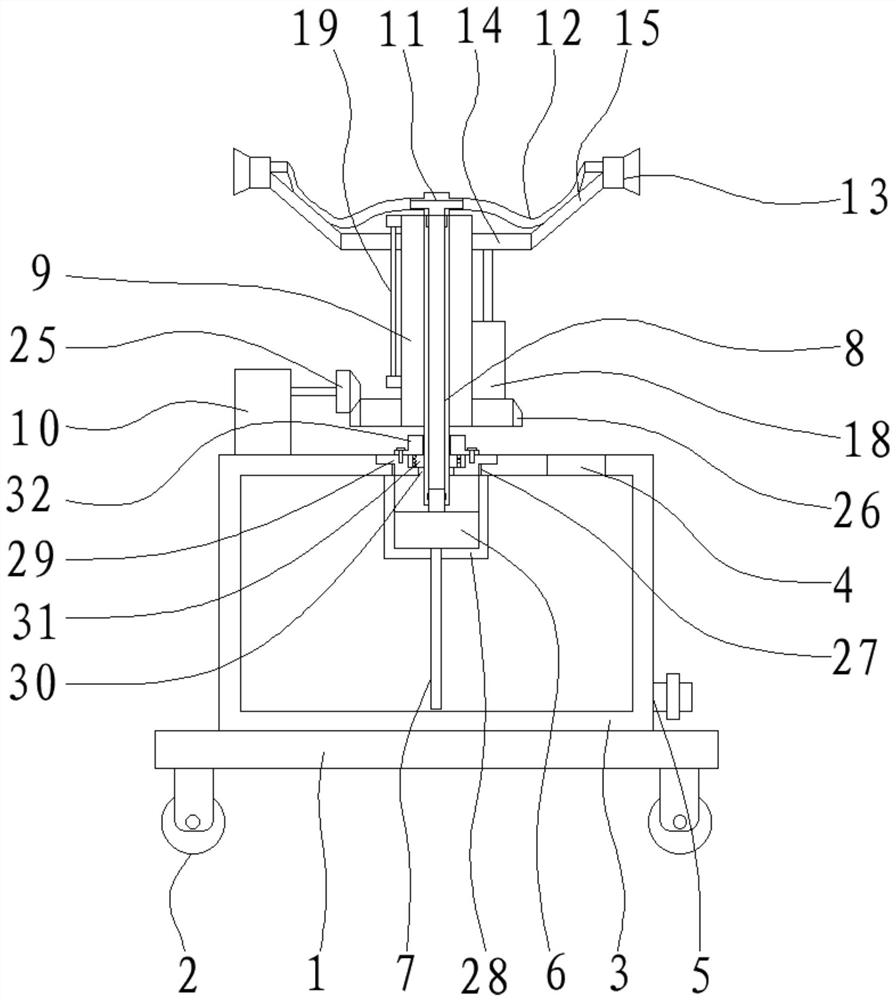

Embodiment 2

[0039] as Figure 2 As shown, the present embodiment includes a base 1, the bottom of the base 1 is provided with a moving wheel 2, in order to facilitate the movement of the base 1, a pushrod may be provided at one end of the base 1 to achieve a manual push of the base 1, and may also be provided on the side wall of the base 1 to provide a hook, connected with a tractor, etc., so as to achieve the movement of the base 1, to achieve the movement of the entire device; The base 1 is fixed on the storage tank 3, the storage tank 3 is provided with an inlet port 4 and an outlet port 5, the inlet port 4 is located at the top of the storage tank 3, the outlet port 5 is provided at the bottom of the side wall of the storage tank 3, and the outlet port 5 is provided with a valve, the top inner wall of the storage tank 3 is fixed on the spray pump 6, the input end of the spray pump 6 is connected to the bottom of the inner cavity of the storage tank 3 through the input tube 7, the output en...

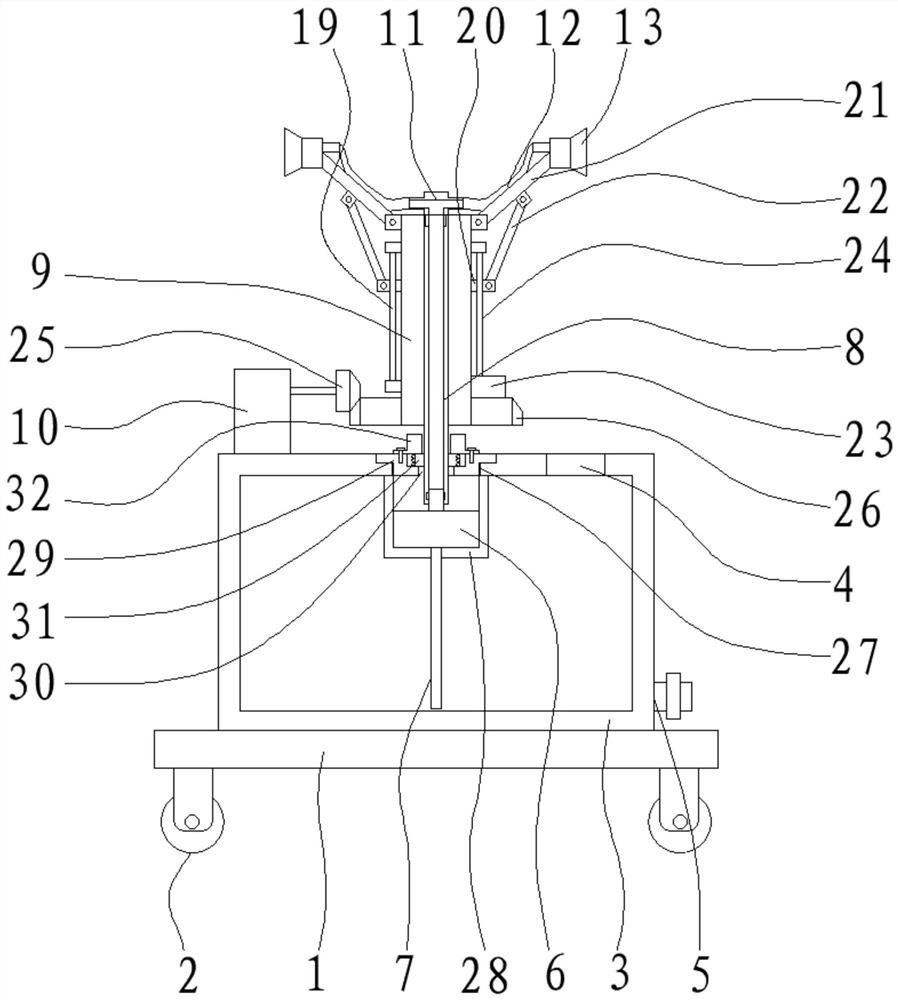

Embodiment 3

[0045] as Figure 3 As shown, the present embodiment includes a base 1, the bottom of the base 1 is provided with a moving wheel 2, in order to facilitate the movement of the base 1, a pushrod may be provided at one end of the base 1 to achieve a manual push of the base 1, and may also be provided on the side wall of the base 1 to provide a hook, connected with a tractor, etc., so as to achieve the movement of the base 1, to achieve the movement of the entire device; The base 1 is fixed on the storage tank 3, the storage tank 3 is provided with an inlet port 4 and an outlet port 5, the inlet port 4 is located at the top of the storage tank 3, the outlet port 5 is provided at the bottom of the side wall of the storage tank 3, and the outlet port 5 is provided with a valve, the top inner wall of the storage tank 3 is fixed on the spray pump 6, the input end of the spray pump 6 is connected to the bottom of the inner cavity of the storage tank 3 through the input tube 7, the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com