Automobile seat

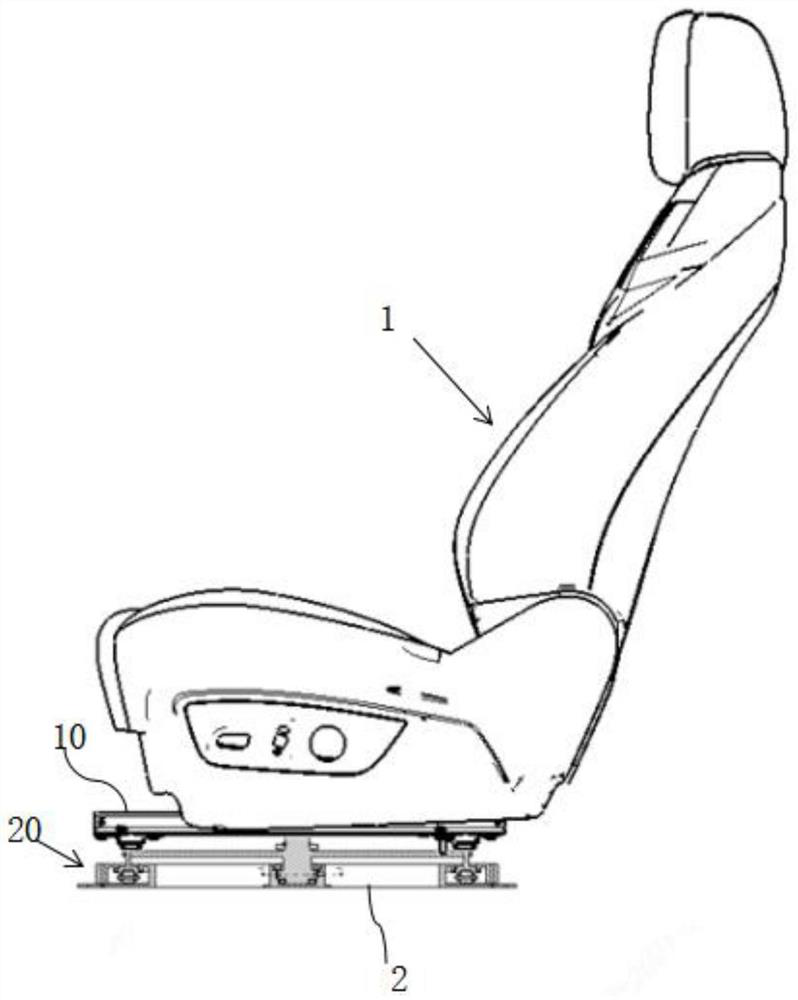

A car seat and seat technology, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve the problems of increasing the height of the seat space, increasing the complexity of the structure, and the difficulty of processing, so as to save time for design , to ensure stability and anti-tipping performance, and to save material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

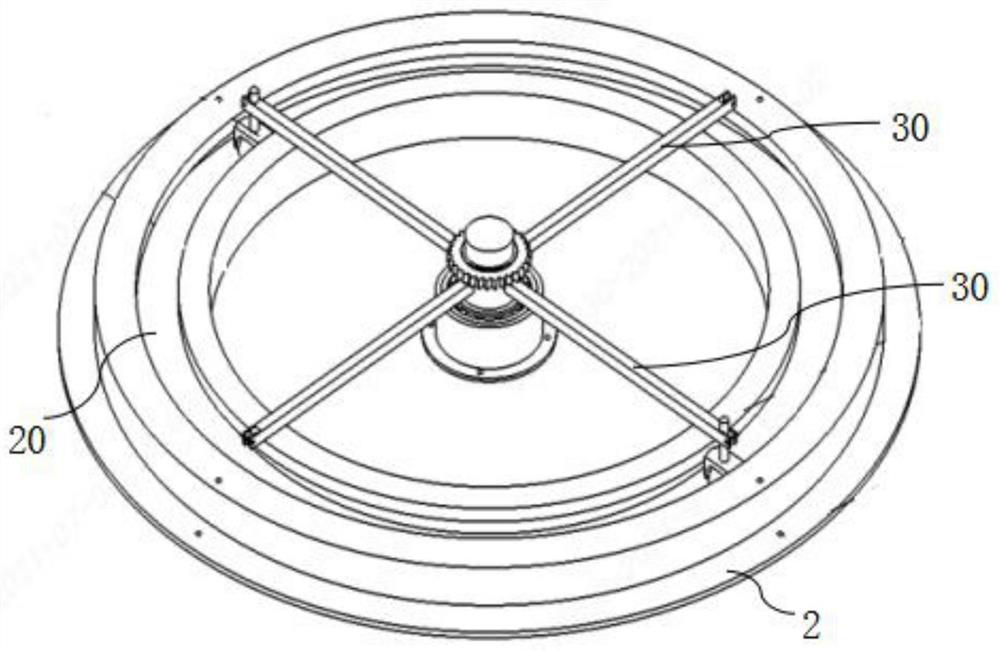

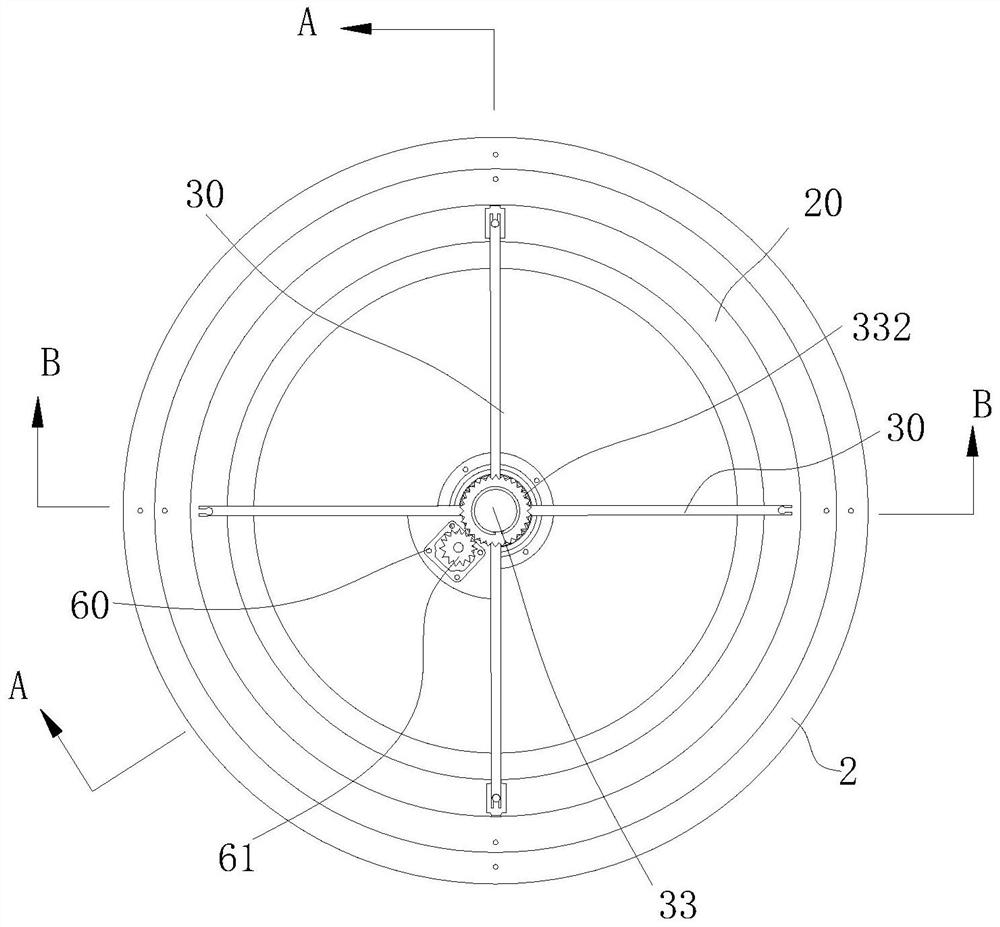

[0018] One is: the cross-section of the annular track 20 is a closed groove with the notch upward, and the roller 31 provided on the turret 30 is placed in the groove cavity of the annular track 20 and forms a rolling fit with the bottom of the groove, such as: Figures 1 to 5 shown.

[0019] The second is: the circumferential inner and outer side sections of the annular track 20 are in the shape of a concave arc, and the slotted slider 34 on the turret 30 is clamped downward on the annular track 20 . superior.

[0020] The matching structure between the annular track 20 and the groove-shaped slider 34 in the above-mentioned solution 2 can be a linear bearing structure scheme, which can reduce frictional noise and improve the stability of rotating operation, and the groove-shaped slider can be used. 34 is connected to the guide rail 11 in the sliding mechanism assembly 10 , and the grooved slider 34 is also connected to the turret 30 , which will help ensure the reliability a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com