Heading machine

A technology of roadheader and body, applied in mining equipment, tunnels, earth-moving drilling, etc., can solve problems such as reducing production efficiency, increasing labor intensity of workers, and consuming a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

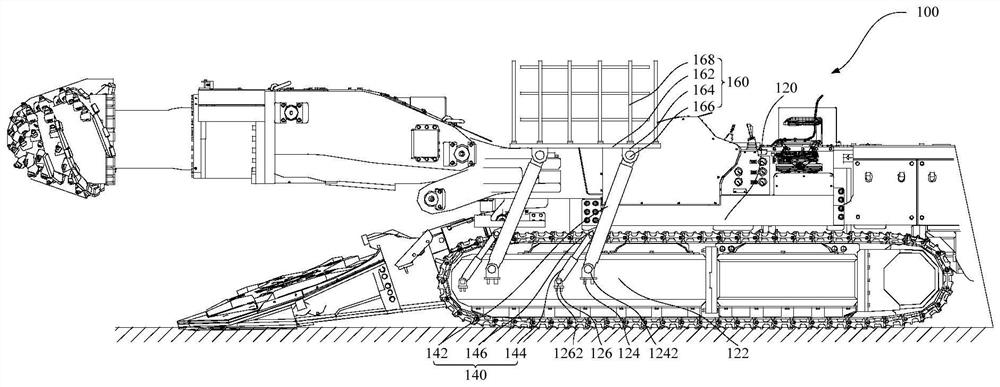

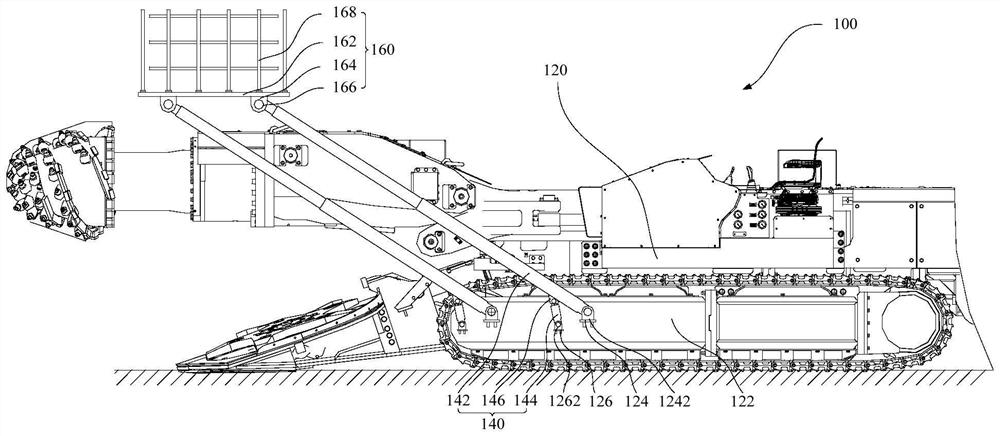

[0044] like figure 1 and figure 2 As shown, the embodiment of the first aspect of the present invention proposes a boring machine 100 , including: a body 120 , a driving device 140 and an anchor protection platform 160 .

[0045] Specifically, the boring machine 100 includes a machine body 120 , and the driving device 140 is disposed on the machine body 120 .

[0046] Further, as figure 1 and figure 2As shown, the roadheader 100 further includes an anchor protection platform 160 , which is connected to the driving device 140 , and the driving force provided by the driving device 140 can drive the anchor protection platform 160 to move relative to the machine body 120 .

[0047] Specifically, the movement of the anchor protection platform 160 relative to the body 120 includes: raising and lowering of the anchor protection platform 160 relative to the body 120 and forward and backward movement of the anchor protection platform 160 relative to the body 120 . By driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com