Ultra-compact gearbox and generator integrated structure

A gearbox and generator technology, applied in wind power generation, belts/chains/gears, transmission boxes, etc., can solve the problems of material redundancy, structural function duplication, and structural dispersion of the gearbox and generator support structures, and achieve savings. The effect of weight, less cost, and compact connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

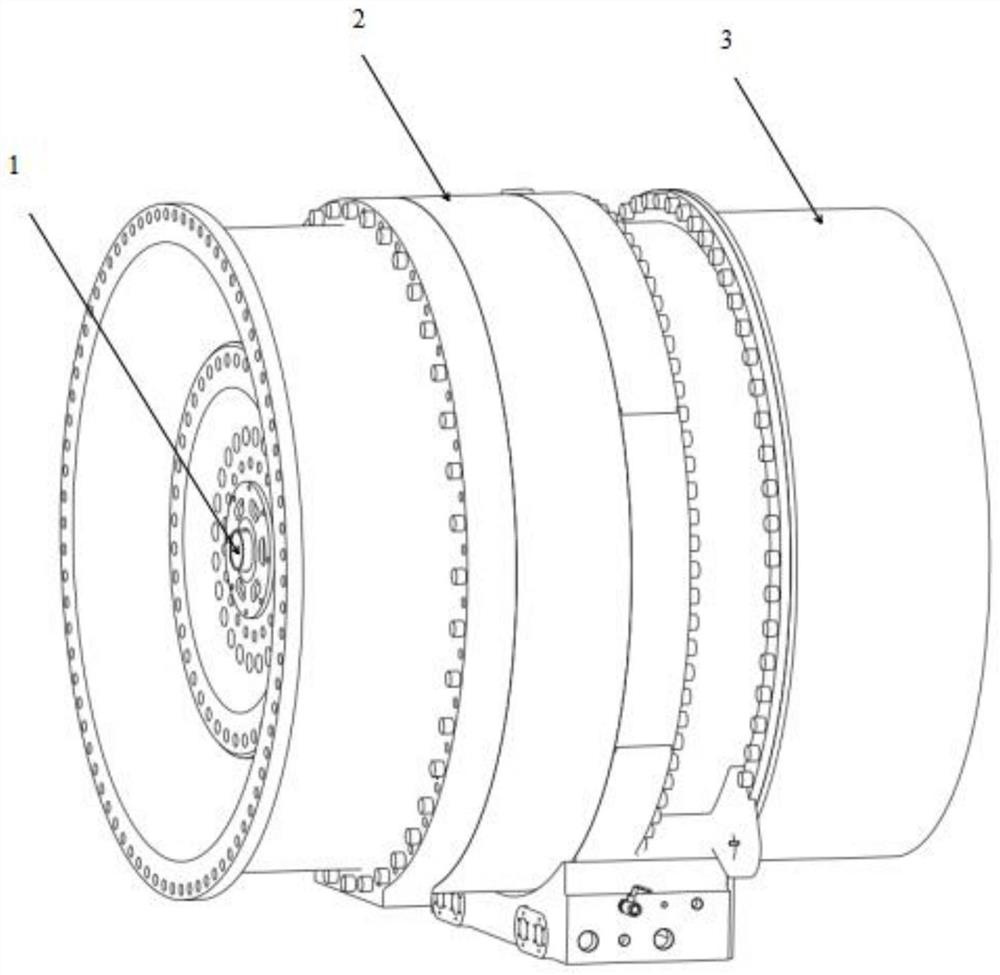

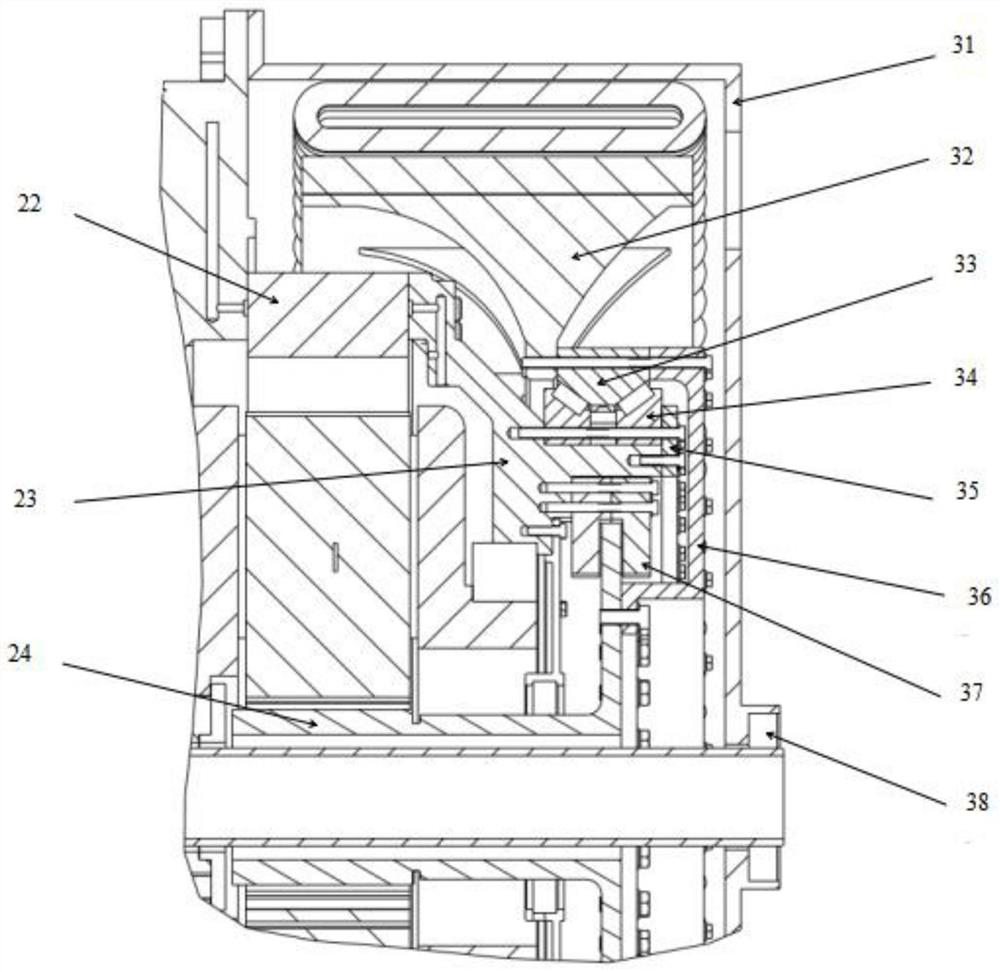

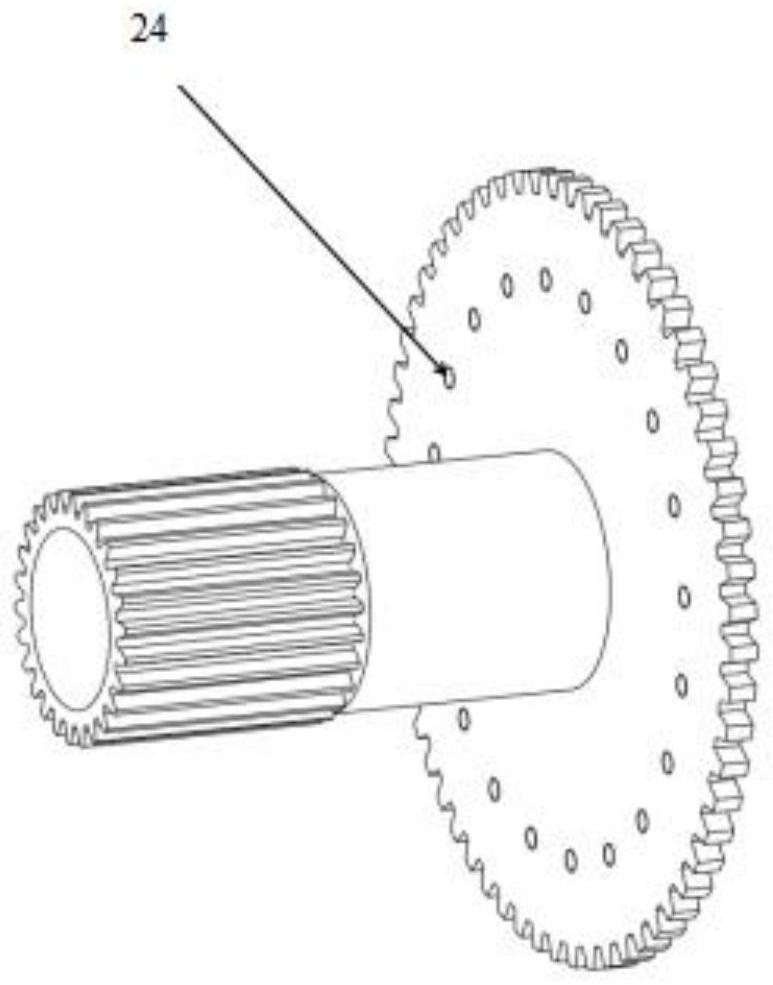

[0021] see Figure 1 to Figure 3 , the present invention provides a technical solution: an ultra-compact gearbox and generator integrated structure, including a gearbox body 2 and a generator body 3, one end of the gearbox body 2 is placed inside one end of the generator body 3, the gear box One end of the box body 2 is fixed with a rear end cover 23 of the gearbox. Through the designed rear end cover 23 of the gearbox and the generator body 3, the rear end cover 23 of the gearbox must bear the load of the secondary planetary carrier 22 and the generator. At the same time, the bearing structure of the generator body 3 adopts a single bearing structure, so that the generator rotor 32 completely acts on the rear end cover 23 of the gearbox, ensuring that the generator rotor 32 is coaxial with the gearbox output shaft 24, The gearbox and some parts of the generator are omitted, which reduces the weight, cost and load. One end of the rear end cover 23 of the gearbox is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com