Self-starting synchronous reluctance motor rotor and motor

A synchronous reluctance motor and self-starting technology, which is applied in the direction of synchronous motors, electromechanical devices, electrical components, etc. for single-phase current, can solve the problems of large torque ripple and large current harmonics, and achieve the solution of current harmonics Larger, lower harmonics, and lower cogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

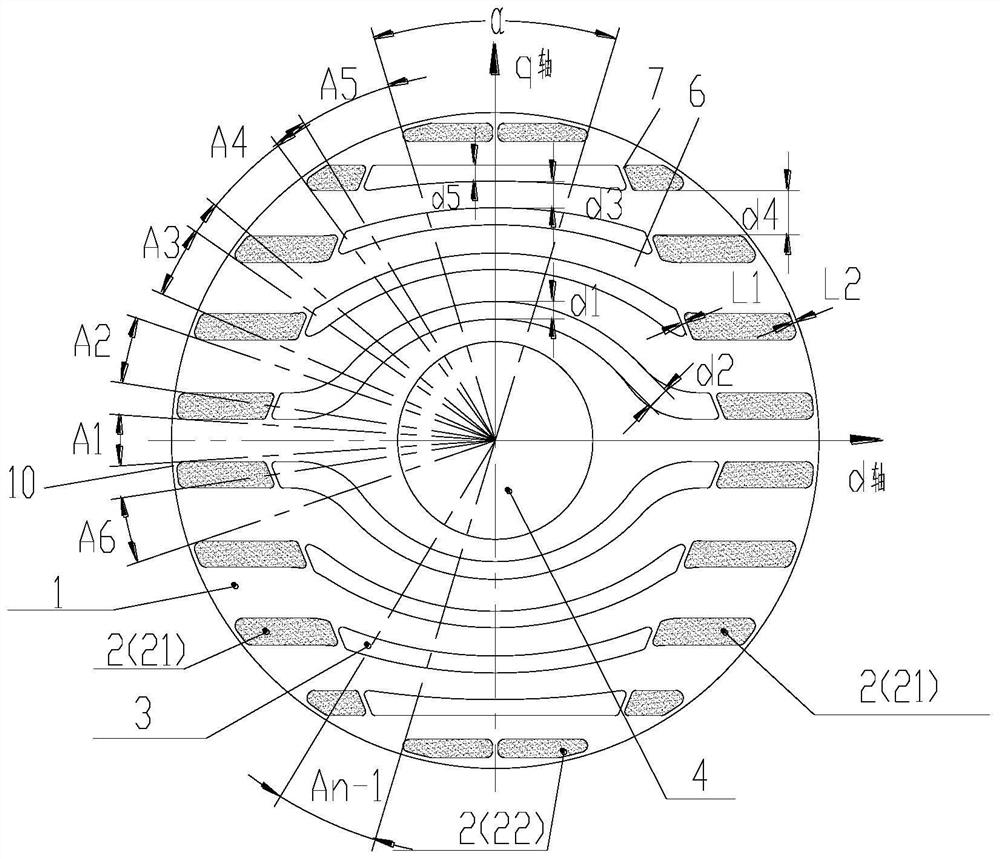

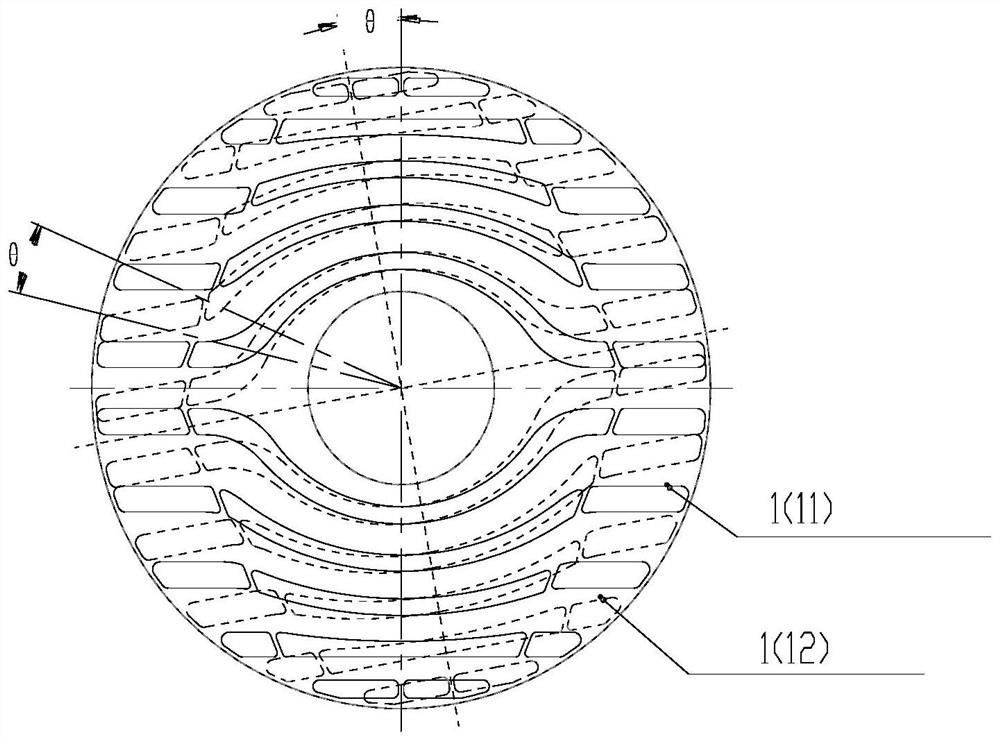

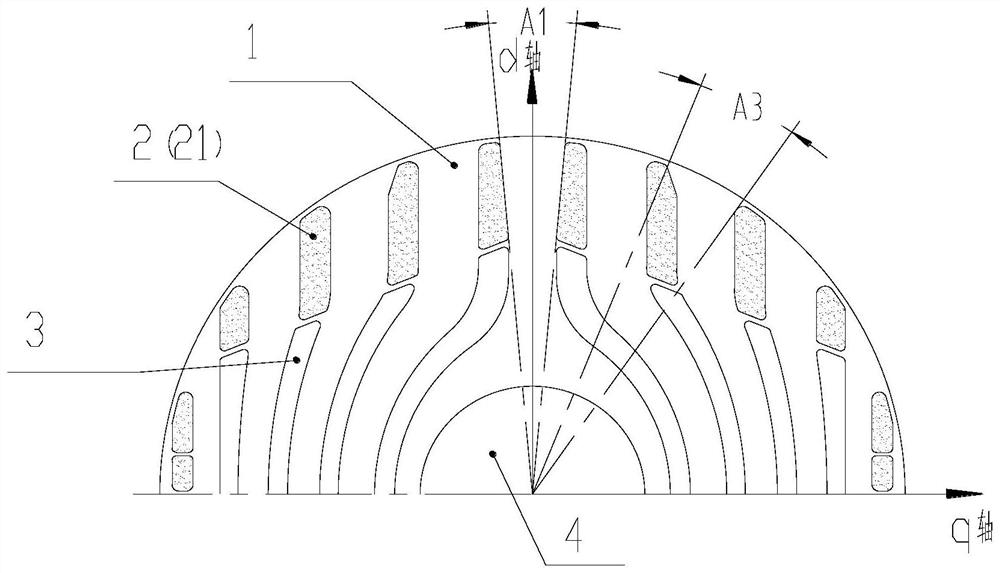

[0034] like Figure 1-5 As shown, the present invention provides a self-starting synchronous reluctance motor rotor, which includes a rotor core, which is formed by laminating a plurality of rotor punches 1, and the rotor punches 1 are provided with filling grooves 2. The slit slot 3 and the shaft hole 4, in the direction from one axial end of the rotor to the other axial end, the next rotor punching piece in the two adjacent rotor punching pieces 1 is relative to the previous rotor punching. The blade rotates around the rotor center by a preset angle, and the rotation directions of all the rotor blanks 1 are in the same direction; so that the rotor blanks located at the other end of the axial direction rotate around the rotor center relative to the rotor blanks located at one end of the axial direction. The angle is θ, where θ>0, and θ is the rotor chute.

[0035] The rotor of the present invention is formed by laminating rotor punching sheets with a specific structure. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com