Composition in container, use thereof, and processed food in container

A composition and container packaging technology, applied in the directions of food ingredients, food ingredients as odor modifiers, applications, etc., can solve problems such as high content and inability to use, and achieve the effects of improving flavor, improving palatability, and inhibiting fishy odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

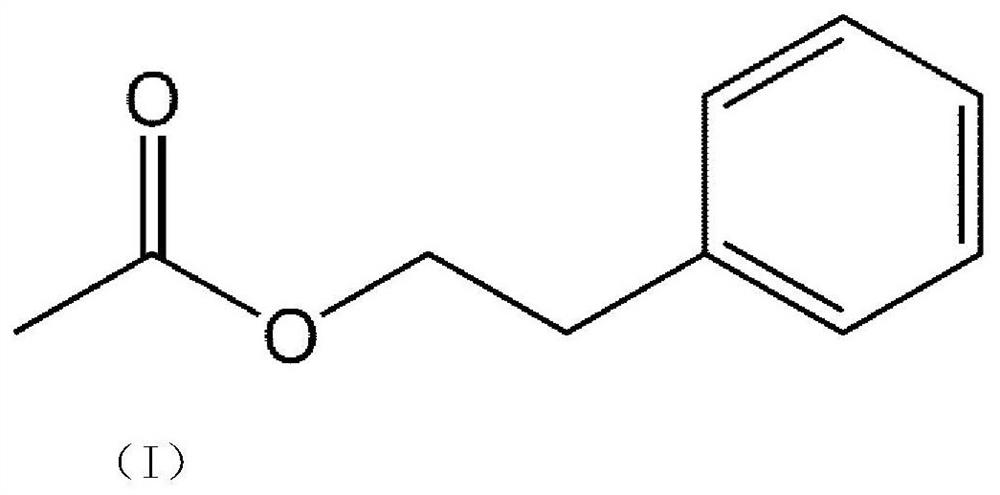

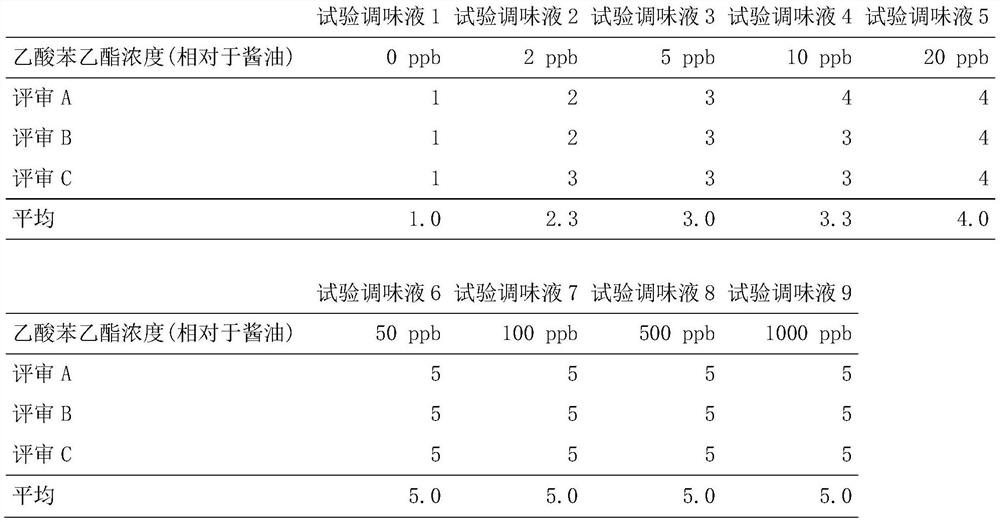

[0269] Example 1 Evaluation of cooking odor inhibition based on phenethyl acetate (1)

[0270] [1-1. Preparation of liquid seasoning]

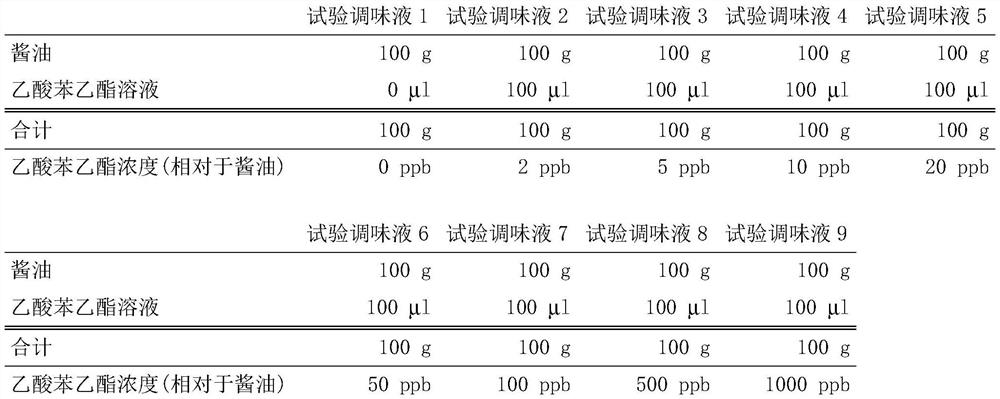

[0271] 1 g of 98% pure phenethyl acetate (Sigma-Aldrich Co. LLC.) was added to a 100 ml volumetric flask, and the volume was adjusted to the mark with 95% ethanol to prepare a phenethyl acetate stock solution (1 g / 100 ml). Next, the phenethyl acetate solution added to each test seasoning was unified to 100 μl, and the phenethyl acetate stock solution was diluted with water so that the phenethyl acetate content with respect to the soy sauce became a predetermined concentration to prepare each phenethyl acetate solution. .

[0272] Each test seasoning liquid was prepared by mixing soy sauce and phenethyl acetate solution in the compounding quantity shown to following Table 1A. It should be noted that the soy sauce used was "Kanji Select Maru soybean soy sauce" (HEMF 30 ppm or more; Nippon Kikkoman Co., Ltd.) in which phenylethyl acetate was ...

example 2

[0290] Example 2 Evaluation of cooking odor inhibition based on phenethyl acetate (2)

[0291] [2-1. Preparation of liquid seasoning]

[0292] In the same manner as in Example 1, each test seasoning liquid was prepared by mixing soy sauce, sugar, kelp extract, and phenethyl acetate solution in the compounding amounts shown in Table 3A below, and adjusting to 100 g as a whole with water, followed by retort sterilization. (121.1°C, 10 minutes (Fo value 10)). In addition, the kelp extract used was "Kobukon Hidaka P" (Japan Kikkoman Food Co., Ltd.).

[0293] [Table 3A]

[0294]

[0295] [2-2. Sensory evaluation results]

[0296] In the same manner as in Example 1, the sensory evaluation was performed after the test seasoning liquids 10 to 12 were retorted and sterilized. The results are shown in Table 4A.

[0297] [Table 4A]

[0298]

[0299]

[0300] As shown in Table 4A, it was found that by including phenylethyl acetate, even when other seasoning components such ...

example 3

[0302] Example 3 Heating cooking test using test seasoning liquid

[0303] [3-1. Preparation of liquid seasoning]

[0304] In the same manner as in Example 1, ground beef, sugar, water, soy sauce, and phenethyl acetate solution were mixed in the compounding amounts shown in Table 5A below to prepare each test seasoning liquid. Here, in the test seasoning liquid 13, all components were mixed, filled in an aluminum bag, and subjected to retort sterilization (121.1° C., 10 minutes (Fo value 10)). The test seasoning liquids 14 to 17 were filled with ingredients such as ground beef, sugar, and water, as well as soy sauce and phenethyl acetate solution, into two aluminum bags, respectively. The aluminum bag of the test seasoning liquid 17 filled with soy sauce and phenethyl acetate solution was used for non-retort sterilization (85° C., 5 minutes (Fo value 0.00126)), and the aluminum bags of the other test seasoning liquids 14 to 17 were used for retort sterilization.

[0305] [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com