Latch assembly, latch device and rocker arm

A latching device, latching technology, applied in valve devices, engine components, machines/engines, etc., can solve the problems of unusable rocker arm function, response time limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Reference will now be made in detail to the illustrated examples in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

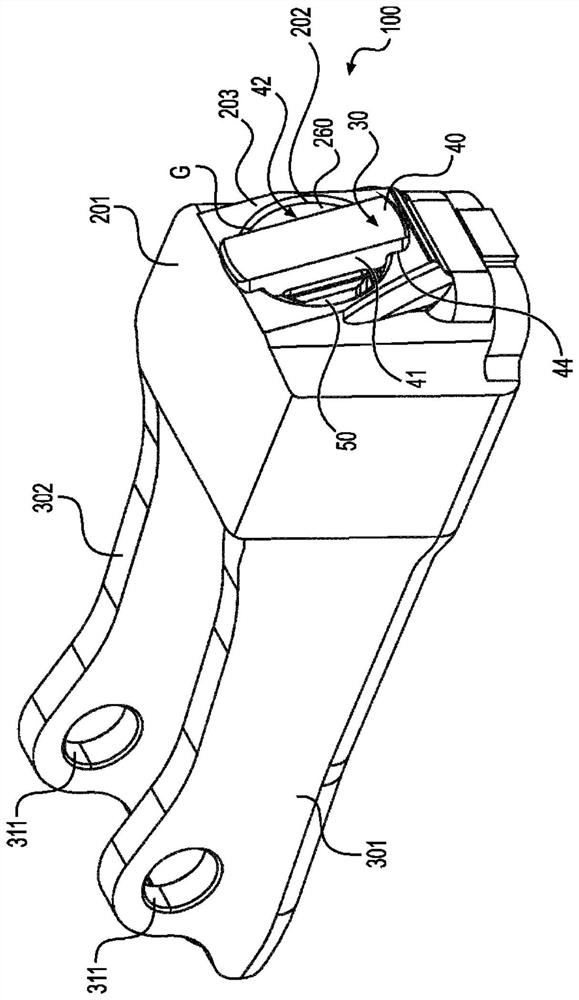

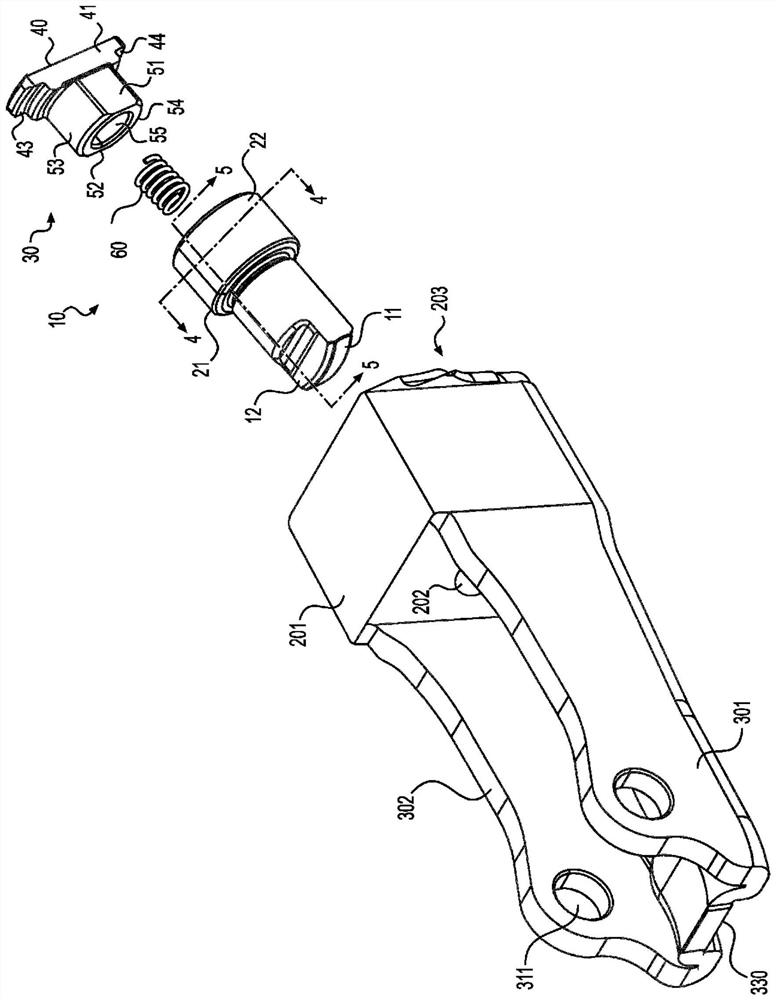

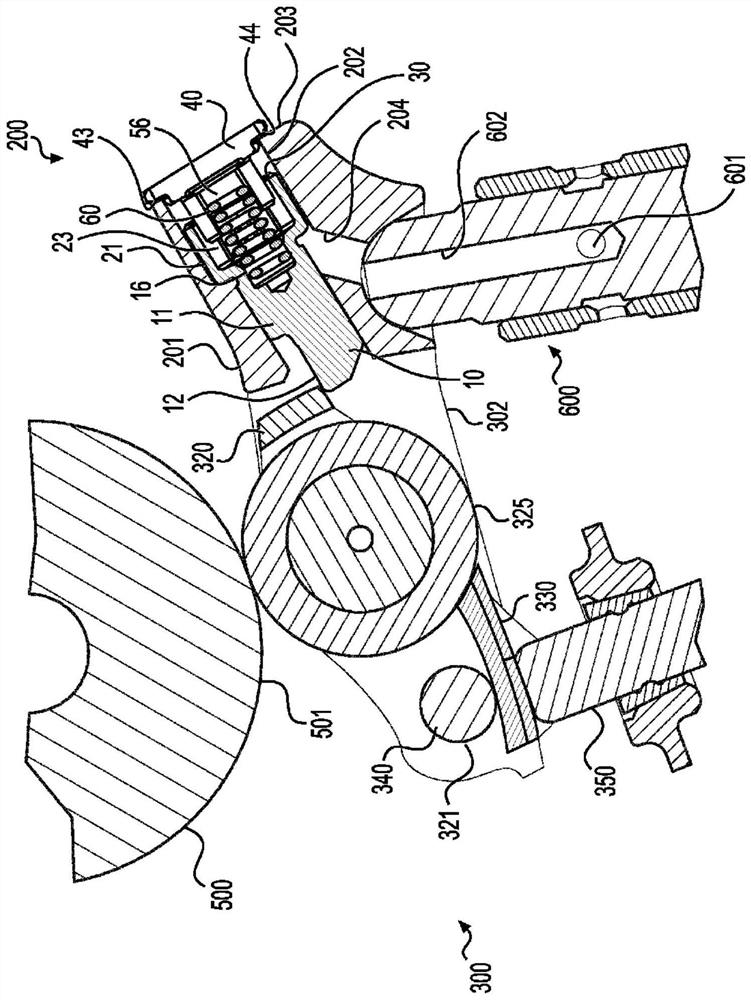

[0019] The present disclosure provides systems and apparatus for adding ventilation to a latch mechanism. The latch assembly 100 may constitute a vented latch mechanism for a hydraulically actuated switching rocker arm 300 or other variable valve train component. The latch assembly 100 is designed to allow for improved response time of the latch pin 10 . The non-circular latch retainer 30 increases the flow area 260 exposed to atmospheric pressure, thereby improving switching performance.

[0020] An optimized latch pin 10 response time may be achieved for switched rocker arm 300 engine applications with low available pressure. The rocker arm 300 may be configured such as Figure 3A latched state shown as well as Figure 3B toggles between the unlatched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com