Prefabricated assembly type structure for building civil engineering construction

A technology of civil engineering and prefabrication, which is applied in the direction of building components, building structures, buildings, etc., to achieve the effects of strengthening connection strength, avoiding rain erosion, and reducing vibration interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

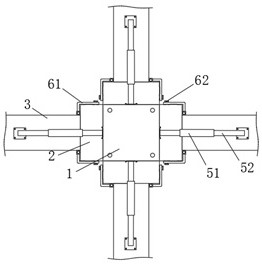

Image

Examples

Embodiment Construction

[0025] Through the above technical solutions:

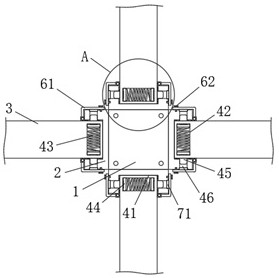

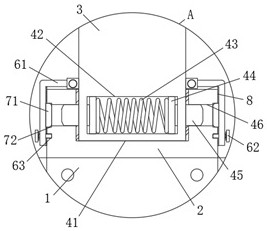

[0026] refer to figure 2 and image 3 , including a sealing assembly; the sealing assembly includes a blocking block 71 and a blocking groove 72, wherein the blocking block 71 is installed on the inner side of the card plate 61, the blocking groove 72 is opened at the end of the limiting hole 46, and the blocking block 71 and the blocking groove 72 correspond match.

[0027] Through the above technical solutions:

[0028] refer to Figure 1-Figure 4 , the inner side of clamping plate 61 is equipped with rubber pad 8, and the outer wall of rubber pad 8 is provided with anti-slip embossing, and the side wall of prefabricated pile 1 is provided with through hole, and the end of prefabricated beam 3 is matched with slot 41, and slot The inner wall of 41 is equipped with a backing plate, and the outer wall of the backing plate is provided with an anti-skid groove, the clamping plate 61 is L-shaped, the end of the blocking block 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com