Full-wrap-angle threshing and separating device and threshing method

A technology of threshing separation and wrapping angle, applied in threshing equipment, agriculture, application, etc., can solve the problems of increasing grain threshing wrapping angle, large equipment occupied space, clogging of threshing drum, etc., to reduce entrainment loss, improve threshing rate, The effect of increased area and striking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further clarified below with reference to the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

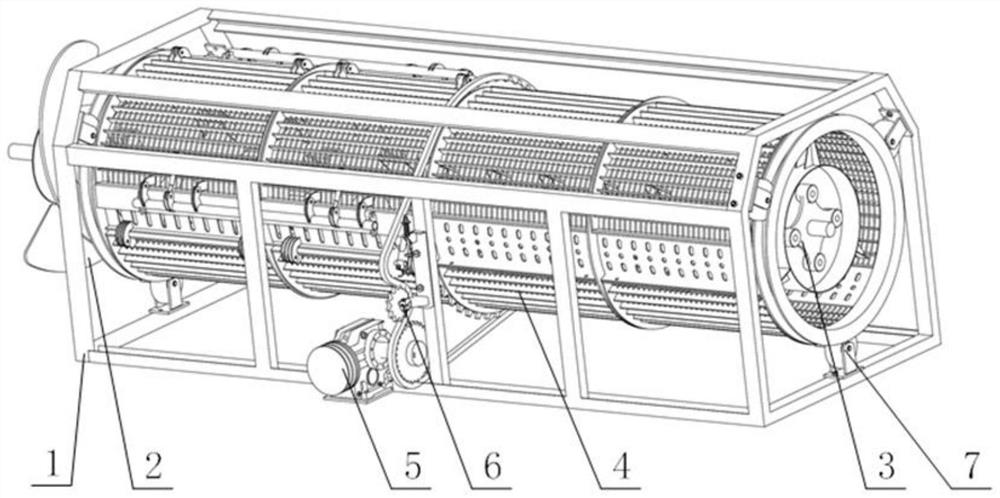

[0049] like figure 1 As shown, an all-inclusive angle threshing separation device for a harvester, comprising:

[0050] Frame 1), the frame 1 is used to support the whole harvester with an all-inclusive angle threshing separation device;

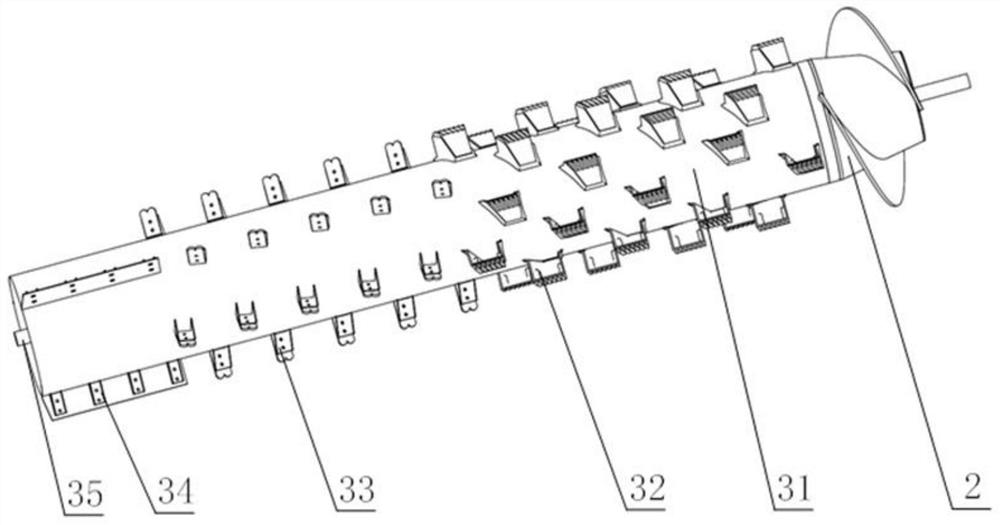

[0051] Conical drum part 2, the conical drum part 2 is installed at the rear end of the feeding bridge of the harvester;

[0052] The threshing drum 3, the threshing drum 3 is installed at the rear end of the tapered drum part 2;

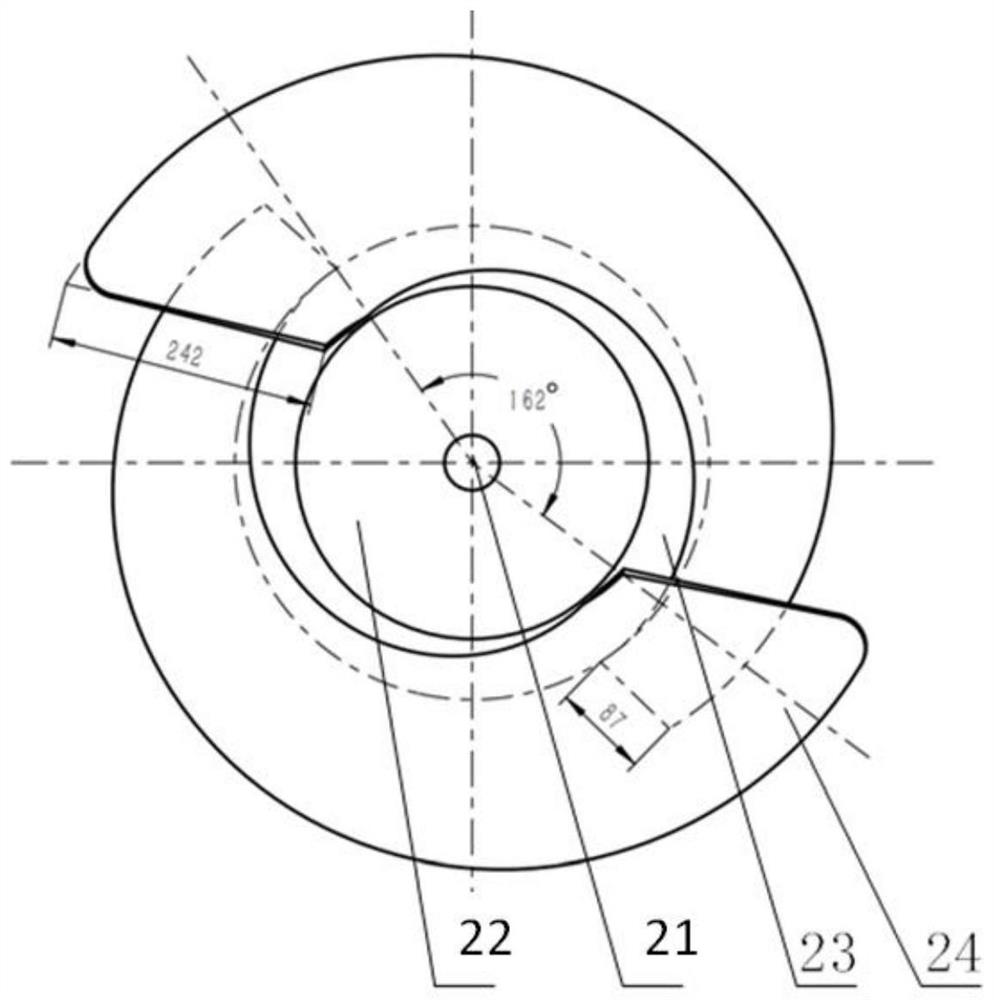

[0053] The concave plate screen 4, the concave plate screen 4 is a hollow cylindrical 360° rotary concave plate screen 4, which is circumferentially arranged on the outer side of the threshing drum 3, and forms a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com