Valve timing control apparatus

A technology of valve timing control and fluid control valves, which is applied in the direction of valve devices, engine components, machines/engines, etc., and can solve the problems of deteriorating the installability of valve timing control devices, lengthening the longitudinal length of valve timing control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

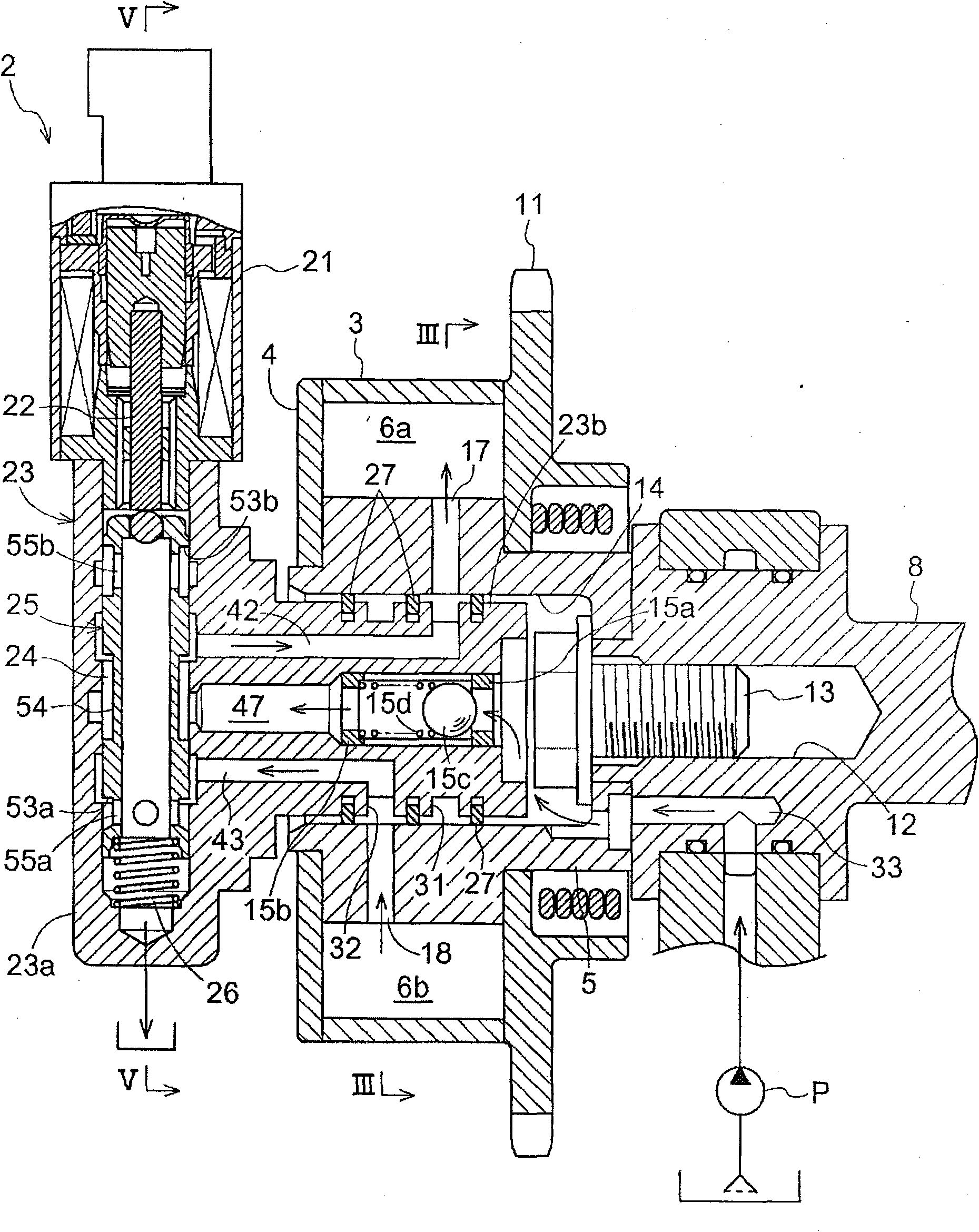

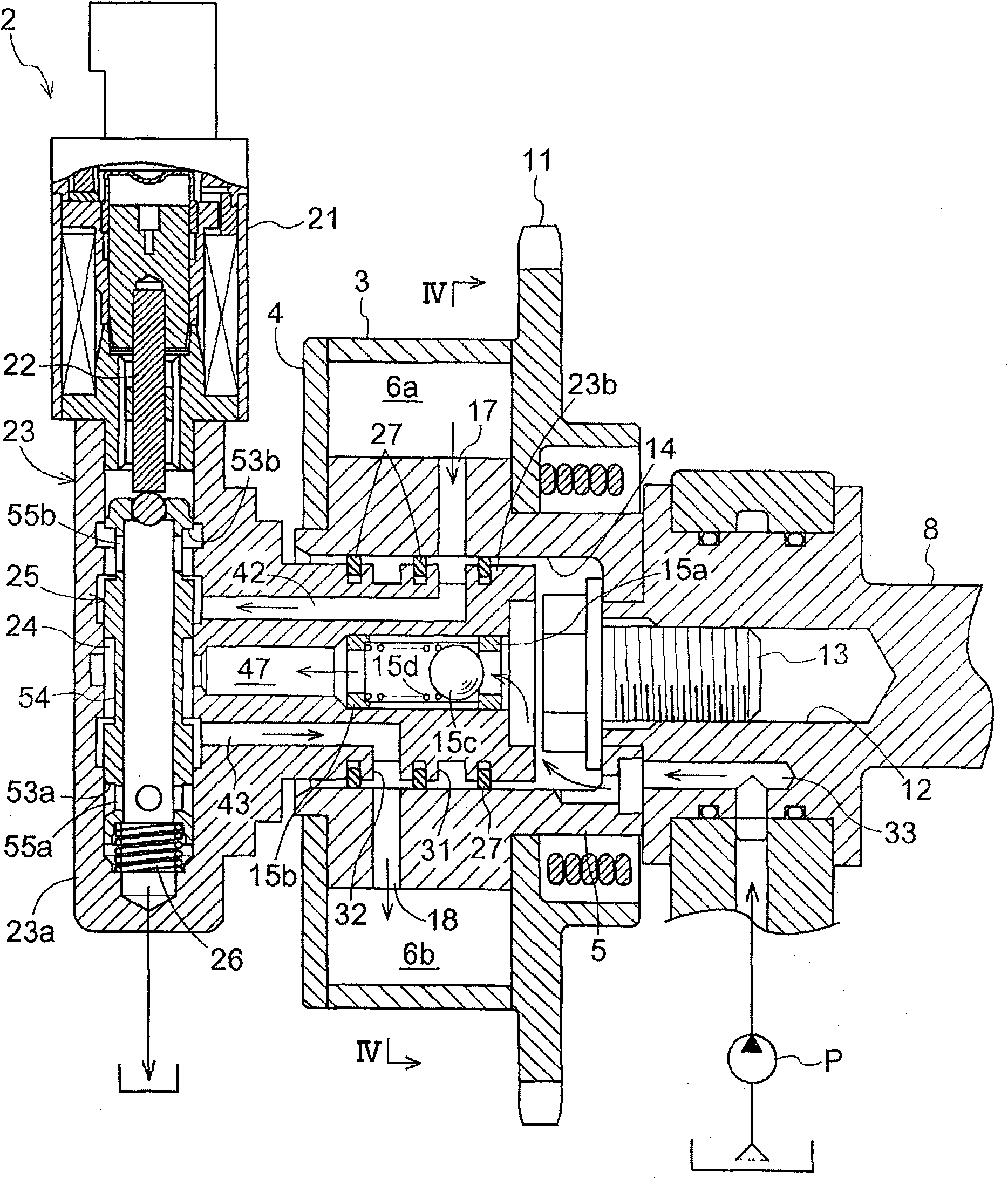

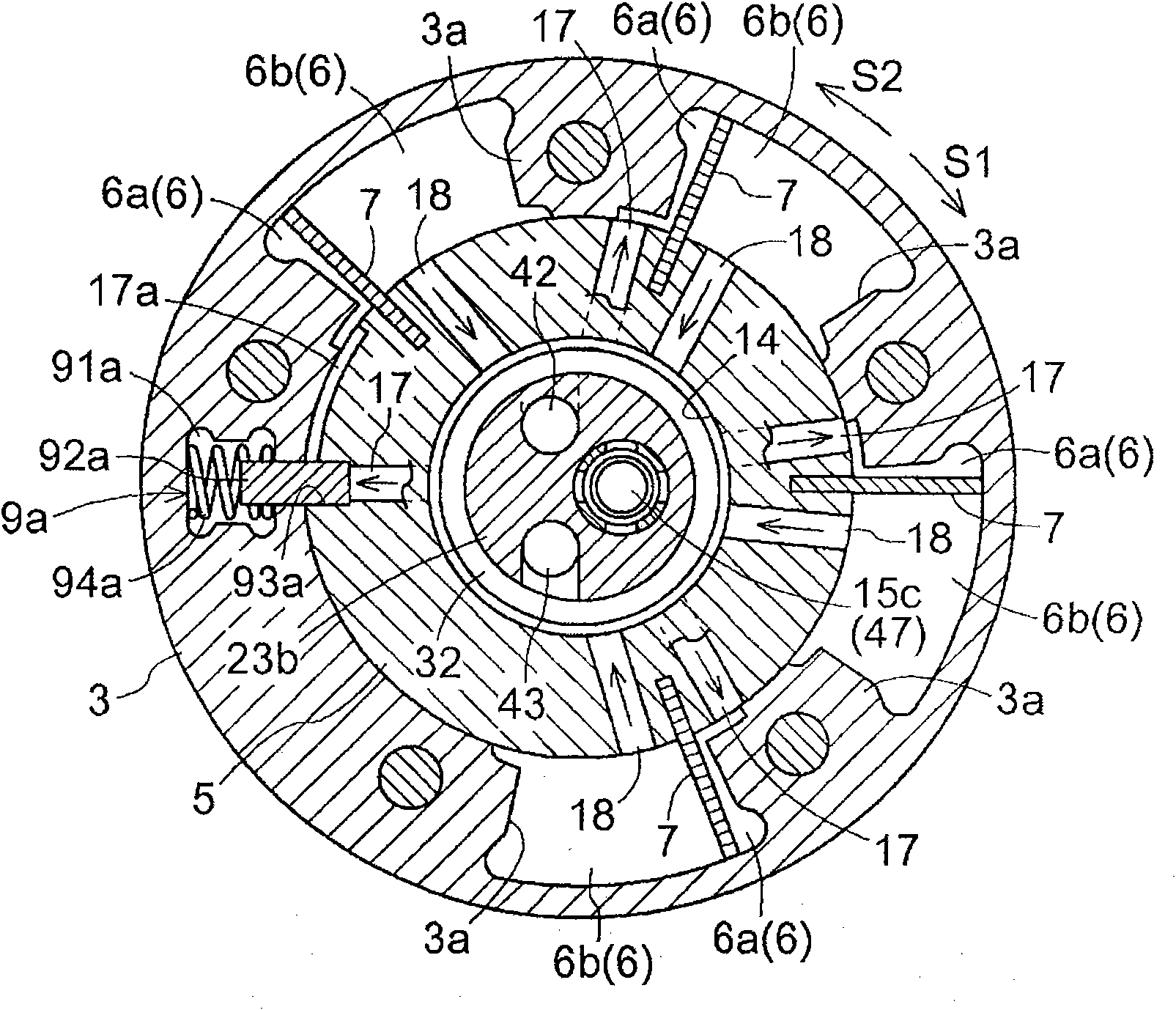

[0030] [the whole frame]

[0031] Such as figure 1As shown, a valve timing control device 1 according to one embodiment includes an outer rotor 3 (driving side rotating member), a front plate 4, and an inner rotor 5 (driven side rotating member). The outer rotor 3 and the front plate 4 rotate synchronously with the crankshaft of the engine. The inner rotor 5 is coaxially arranged with the outer rotor 3 . The outer rotor 3 rotates synchronously with the camshaft 8 for opening and closing the engine valves. The inner rotor 5 is integrally arranged on the end of the camshaft 8, the camshaft 8 constitutes the rotating shaft of the cam, and the cam is used to control the opening and closing of the intake valve and the exhaust valve of the engine. The recess 14 is formed on the radial inner side of the inner rotor 5 (the axis side of the camshaft 8 ) so as to open toward the opposite side of the camshaft 8 (to open toward the front plate 4 ). Furthermore, a fixing hole 12 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com