Cleaning device for cleaning tires of tool car

A technology for cleaning devices and car tires, which is applied to vehicle exterior cleaning devices, vehicle cleaning, and vehicle cleaning equipment. The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

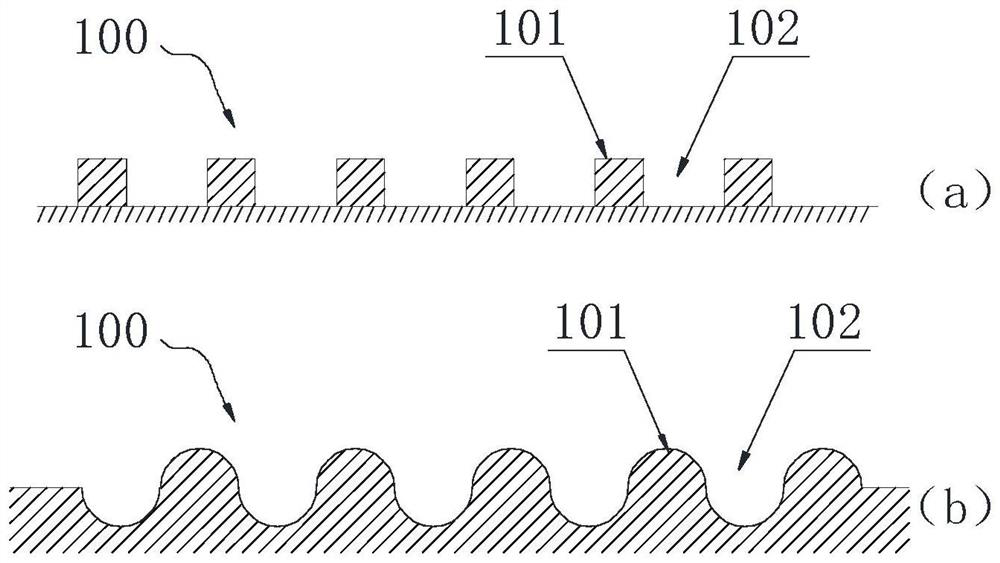

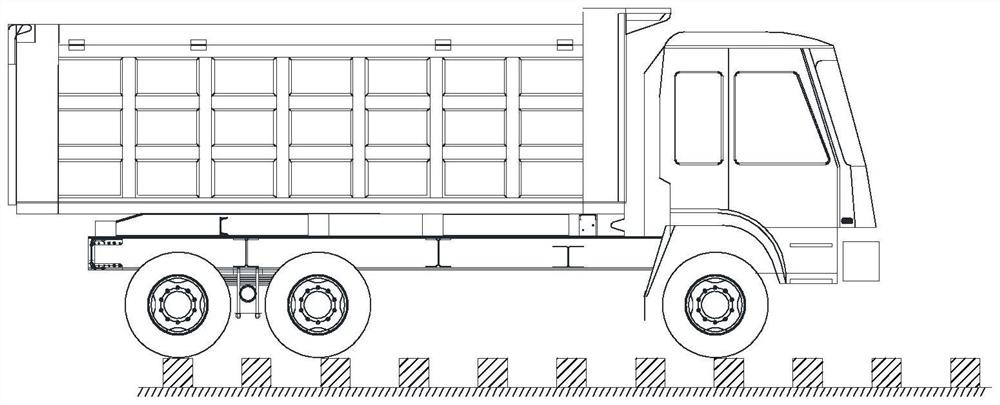

[0029] like figure 1 As shown, the cleaning device for cleaning tires of a tool vehicle includes at least a continuous undulating collision zone 100, the collision zone 100 has a convex collision block 101 and a concave groove 102, and the collision block 101 and the groove 102 are spaced apart from each other set up. like figure 1 As shown in (a) and (b), the different structures of the collision zone 100 are respectively shown. As shown in (a), the collision block 101 of the collision zone 100 has a rectangular cross-section, and the groove 102 also has a rectangular cross-section. , as shown in (b), the collision block 101 of the collision area 100 has a semicircular or fan-shaped section, and the groove 102 is also a semi-circular or fan-shaped section. Of course, the cross-sections of the collision block 101 and the groove 102 may also be different combinations of the above-mentioned rectangular cross-sections, semicircular or fan-shaped cross-sections, or other cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com