A kind of packaging equipment for automatic flipping and demoulding for food processing

An automatic flipping and food processing technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of inability to ensure smooth flipping of soybean products, complex handling and repeated loading and unloading processes, and affecting the shape of tofu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

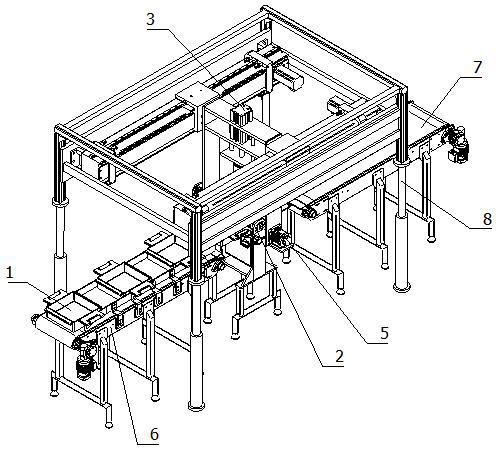

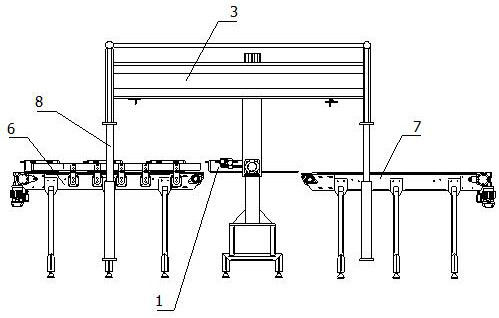

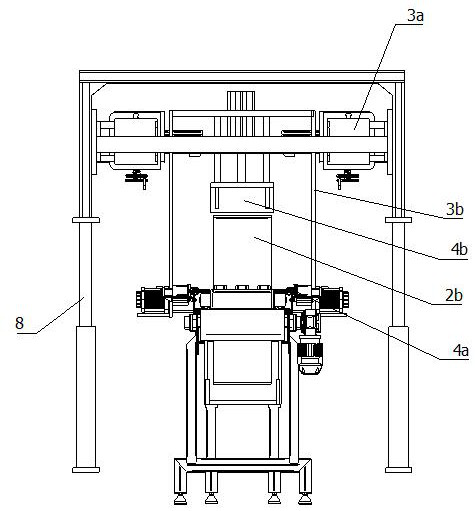

[0042] like Figure 1-8 shown:

[0043] A packaging equipment for automatic flipping and demoulding for food processing, comprising a rectangular frame 1, a flipping stopper mechanism 2, a material shifting mechanism 3, a clamping mechanism, a flipping drive mechanism 5, a feeding conveyor belt 6, a feeding conveyor belt 7 and Lifting frame 8, the transmission direction of the feeding conveyor belt 6 and the feeding conveyor belt 7 is the same, the overturning stopper mechanism 2 is located between the feeding conveyor belt 6 and the feeding conveyor belt 7, the feeding mechanism 3 is fixedly installed on the lifting frame 8, and the overturning drive The mechanism 5 is installed on the output end of the moving mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com