An IoT-based edge box

An Internet of Things and edge technology, applied in the direction of cooling/ventilation/heating transformation, alarms, instruments, etc., can solve problems such as poor hardware heat dissipation, and achieve the effect of increasing retention time and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

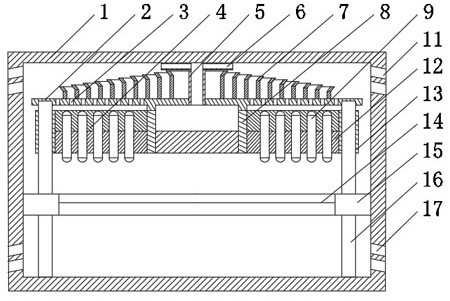

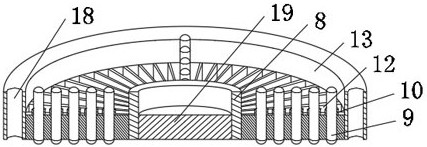

[0025] like figure 1 and figure 2 As shown, this embodiment includes a casing 1, a hardware circuit board 14 is arranged inside the casing 1, an interface module electrically connected to the hardware circuit board 14 is arranged on the outer wall of the casing 1, and a heat dissipation device is arranged above the hardware circuit board 14 The heat dissipation system includes a coaxial inner ring body 8 and an outer ring body 13, a plurality of primary fins 12 are provided on the outer circumferential wall of the inner ring body 8 along the radial direction of the inner ring body 8, and the inner ring body 8 passes through the primary fins. The sheet 12 is connected to the outer ring body 13, and a plurality of heat pipes 9 are arranged at intervals between the side walls of the two adjacent primary fins 12, and copper pillars 19 are fixed inside the inner ring body 8; The bottom plate 2 on the upper end face of the body 13, a plurality of overflow holes 3 are opened on the...

Embodiment 2

[0032] like figure 1 and figure 2 As shown, on the basis of Embodiment 1, this embodiment further defines the diversion fins that play a secondary heat dissipation function.

[0033] That is, in this embodiment, the axial lengths of the plurality of the drainage fins are set to decrease from the inside to the outside along the radial direction of the inner ring body 8 . The heat located at the periphery of the hardware circuit board 14 passes through the primary fins 12 after mixing with the air, and then enters the annular diversion fins after passing through the overflow holes 3. The axial lengths of the plurality of diversion fins are along the inner ring body. The radial direction of 8 decreases from the inside to the outside, so that a plurality of hot air flow conduction channels with decreasing heights can be formed above the bottom plate 2, so that the heat carried by the hot air when it moves up in the drainage fins of different heights has a decaying trend. That i...

Embodiment 3

[0040] like figure 1 and figure 2 As shown, on the basis of Embodiment 1, this embodiment also includes a plurality of positioning cylinders 10 arranged in the filling layer 4 and matched with the heat pipes 9, and the lower end surfaces of the positioning cylinders 10 are fixed on two adjacent places. On the upper end of the primary fin 12, the middle part of the heat pipe 9 is expanded to the positioning cylinder 10; At least two positioning holes 18 are formed on the lower end surface of the casing 1 . The bottom of the casing 1 is provided with a guide post 16 . The hardware circuit board 14 is connected to the inner wall of the housing 1 through the heat insulating plate 15, so that the heat generated by each component due to work will not be directly conducted to the housing 1, and the heat insulating plate 15, the inner ring body are sequentially connected to the heat insulating plate 15 and the inner ring body through the guide post 16. 8 and the bottom plate 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com