Electromagnetic shielding film and circuit board

An electromagnetic shielding film and circuit board technology, applied in the field of electronics, can solve the problems of unsatisfactory roughness of the insulating layer, poor bonding strength between the insulating layer and the shielding layer, delamination between the insulating layer and the shielding layer, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

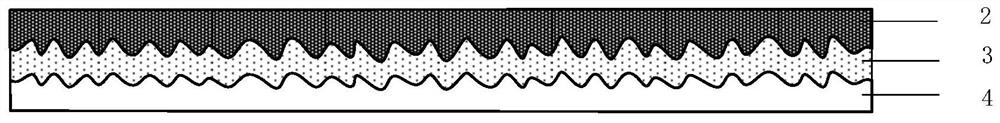

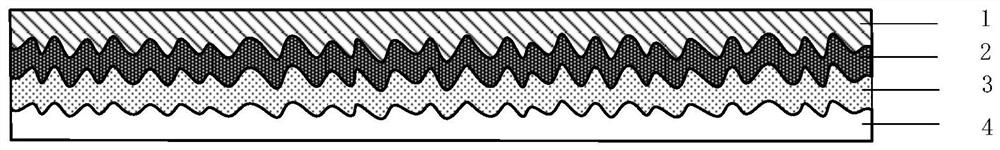

[0065]具体地,当所述电磁屏蔽膜包括载体层1、绝缘层2、屏蔽层3、胶膜层4及保护膜层5时,所述电磁屏蔽膜的制备方法包括:

[0066]1)准备载体层1;

[0067]2)在载体层1的一面上形成绝缘层2;

[0068]3)在绝缘层2的远离载体层1的一面上形成屏蔽层3;

[0069]4)在屏蔽层3的远离绝缘层2的一面上涂覆胶而形成胶膜层4;

[0070]5)在胶膜层4的远离屏蔽层3的一面上贴合保护膜层5。

Example Embodiment

[0072]实施例一:

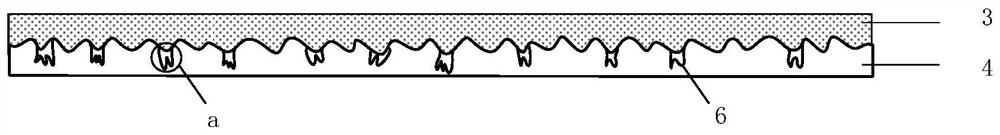

[0073]一种电磁屏蔽膜,包括绝缘层、屏蔽层及胶膜层;所述屏蔽层形成于所述绝缘层的一面上,所述胶膜层设于所述屏蔽层的远离所述绝缘层的一面上;其中,所述绝缘层的靠近所述屏蔽层的一面的粗糙度Rz为0.09微米,所述胶膜层的胶克重参数为0.01克每平方分米,所述绝缘层的靠近所述屏蔽层的一面的粗糙度Rz与所述胶膜层的胶克重参数两者的数值的比例为9。

[0074]测试结果:经过测试,本实施例的电磁屏蔽膜的所述绝缘层和所述屏蔽层之间的分离拉力大于12.23N / cm,本实施例的电磁屏蔽膜压合到线路板后胶膜层的胶溢出的长度小于78μm。

[0075]由此可见,通过应用本实施例的所述电磁屏蔽膜,能够提高电磁屏蔽膜的绝缘层与屏蔽层之间的接着强度,避免在弯折电磁屏蔽膜时容易使得绝缘层与屏蔽层之间出现分层的现象,并且在将所述电磁屏蔽膜压合到线路板后,所述电磁屏蔽膜与线路板之间具有良好的粘合强度的同时,还能让线路板具有良好的外观。

Example Embodiment

[0076]实施例二:

[0077]一种电磁屏蔽膜,包括绝缘层、屏蔽层及胶膜层;所述屏蔽层形成于所述绝缘层的一面上,所述胶膜层设于所述屏蔽层的远离所述绝缘层的一面上;其中,所述绝缘层的靠近所述屏蔽层的一面的粗糙度Rz为14.68微米,所述胶膜层的胶克重参数为1克每平方分米,所述绝缘层的靠近所述屏蔽层的一面的粗糙度Rz与所述胶膜层的胶克重参数两者的数值的比例为14.68。

[0078]测试结果:经过测试,本实施例的电磁屏蔽膜的所述绝缘层和所述屏蔽层之间的分离拉力大于16.78N / cm,本实施例的电磁屏蔽膜压合到线路板后胶膜层的胶溢出的长度小于90μm。

[0079]由此可见,通过应用本实施例的所述电磁屏蔽膜,能够提高电磁屏蔽膜的绝缘层与屏蔽层之间的接着强度,避免在弯折电磁屏蔽膜时容易使得绝缘层与屏蔽层之间出现分层的现象,并且在将所述电磁屏蔽膜压合到线路板后,还能让线路板具有良好的外观。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com