Weld joint feature extraction device and method

A weld seam feature extraction device technology, which is applied in the field of weld seam feature extraction devices, can solve the problems of discontinuous height value, memory occupation, and failure to find, etc., and achieve the effect of improving the seam tracking accuracy

Active Publication Date: 2022-06-21

先富斯技术(武汉)有限公司

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The search speed of this method is slow, takes up a lot of computer memory, and the calibrated height values are discontinuous, and some height values cannot be found in the table

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

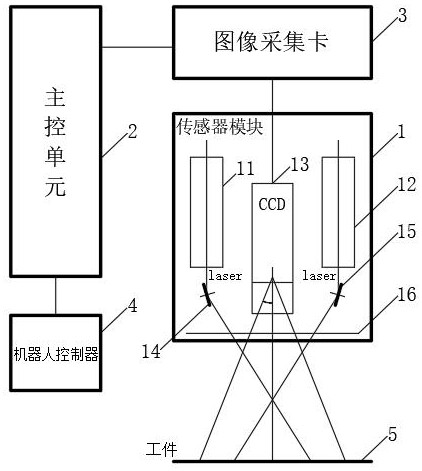

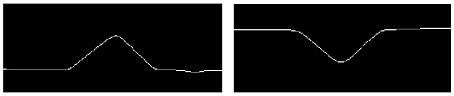

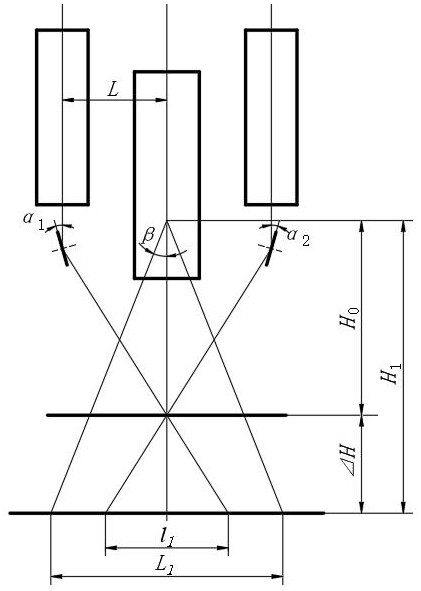

The invention provides a welding seam feature extraction device and method. The device comprises a main control unit, and a robot controller and an image acquisition card which are connected with the main control unit, and further comprises a sensor module which mainly consists of a first laser, a second laser and a CCD (Charge Coupled Device) camera and is arranged at the front end of a welding gun, the first laser and the second laser are used for irradiating laser signals to a workpiece; the CCD camera is used for acquiring an image signal containing double laser stripes on a workpiece, and the image signal is converted into a digital signal through the image acquisition card and then is sent to the main control unit; the main control unit is used for obtaining welding gun height and welding seam tracking deviation through welding seam feature extraction, sending deviation signals to the robot controller and controlling a welding gun on the welding robot to be aligned with a welding seam. The two lasers are arranged on the sensor module, the welding gun height and the welding seam tracking deviation can be accurately obtained, and therefore the welding seam tracking precision is improved.

Description

technical field [0001] The invention belongs to the technical field of welding processing, and in particular relates to a welding seam feature extraction device and method. Background technique [0002] Welding refers to the process of using heat or pressure or both at the same time to make the atoms of the workpiece to be welded penetrate each other, so as to achieve a firm connection. Welding technology is widely used, and is currently mainly used in various industrial sectors such as aviation, aerospace, ships, bridges, large hoisting machinery, and national defense. At present, welding robots are widely used at home and abroad to realize automatic welding. In places that are difficult to reach manually and in some dangerous places, such as aerospace, deep sea, and narrow space areas, welding robots are required for automatic welding. Seam tracking is an important means to realize automatic welding, which can improve the quality of products. The so-called seam tracking...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K37/02B23K31/02B25J9/16

CPCB23K37/0252B23K31/02B25J9/1628B25J9/1697

Inventor 朱明星

Owner 先富斯技术(武汉)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com