Automobile transmission shaft polishing device based on intelligent automobile manufacturing

A technology of intelligent manufacturing and transmission shaft, applied in grinding/polishing safety devices, manufacturing tools, grinding machines, etc., can solve the problems of unstable clamping, increase structure, etc., to increase the transmission effect and prevent the effect of jamming

Pending Publication Date: 2022-06-21

邵彭伟

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing grinding devices for automobile transmission shafts, such as a high-efficiency grinding device for processing automobile transmission shafts with a dust removal function disclosed in Patent No. CN202120582736. The part supports the bottom end of the transmission shaft, so that it is stable and the transmission shaft is ground by the upper grinding roller, but its clamping is not stable and it needs to use multiple linear drives during the clamping process, which greatly increases the complexity of its structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

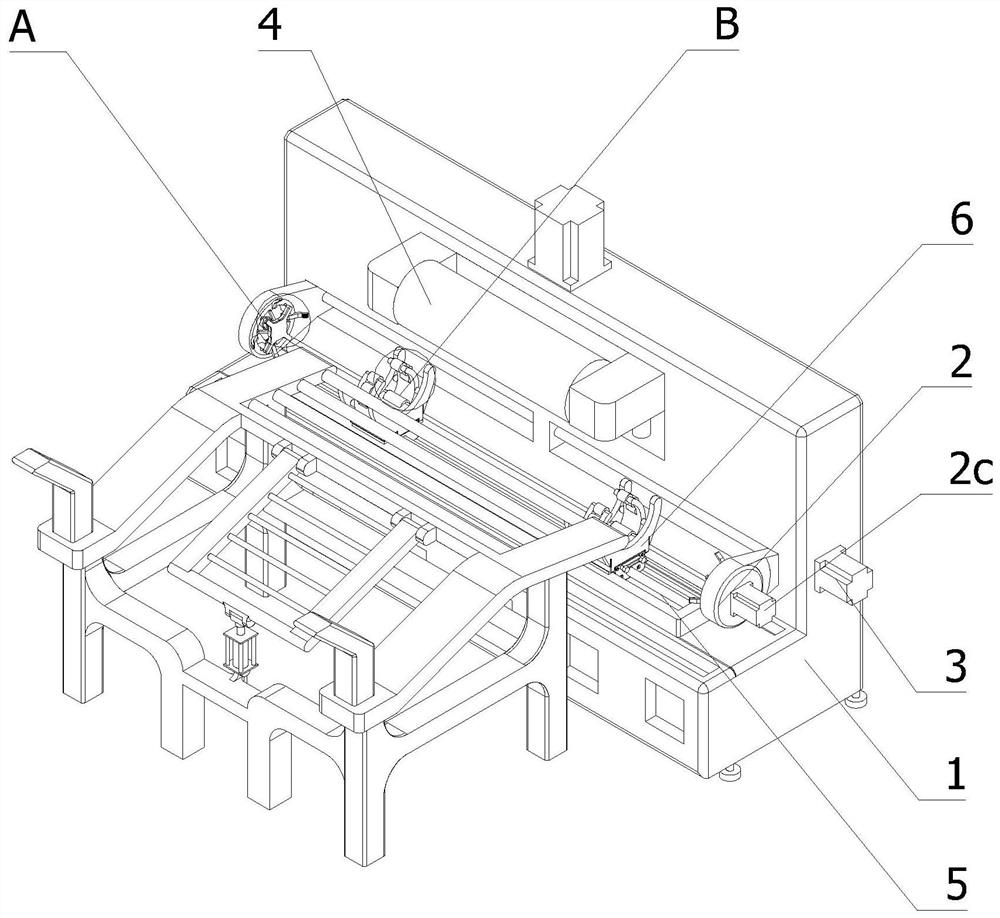

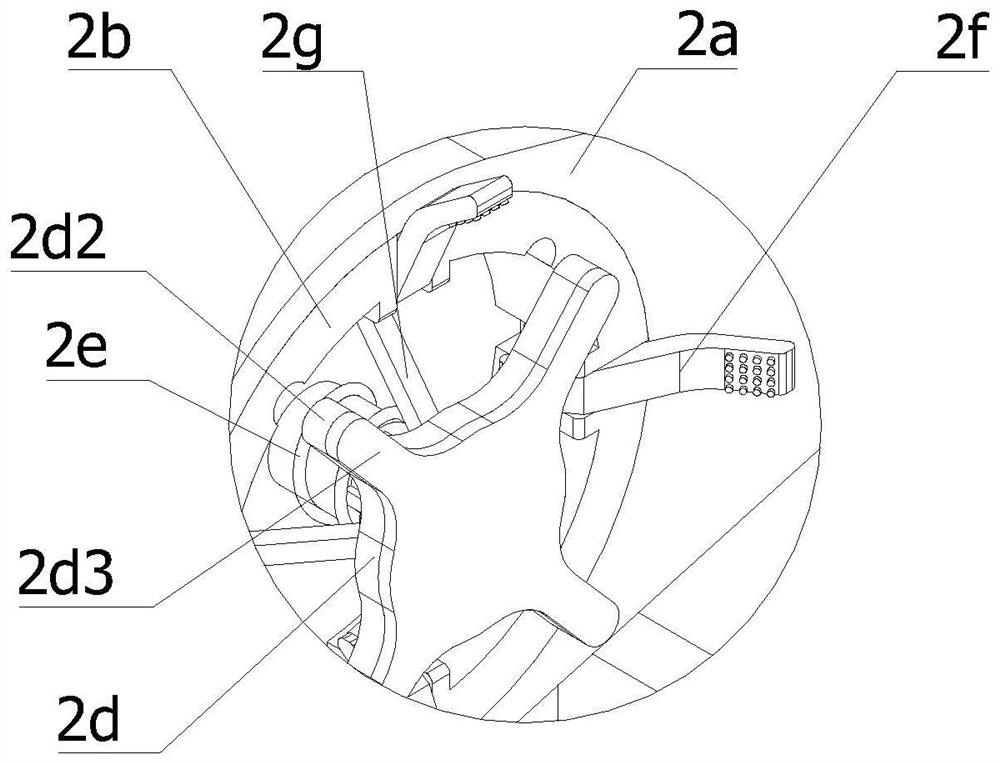

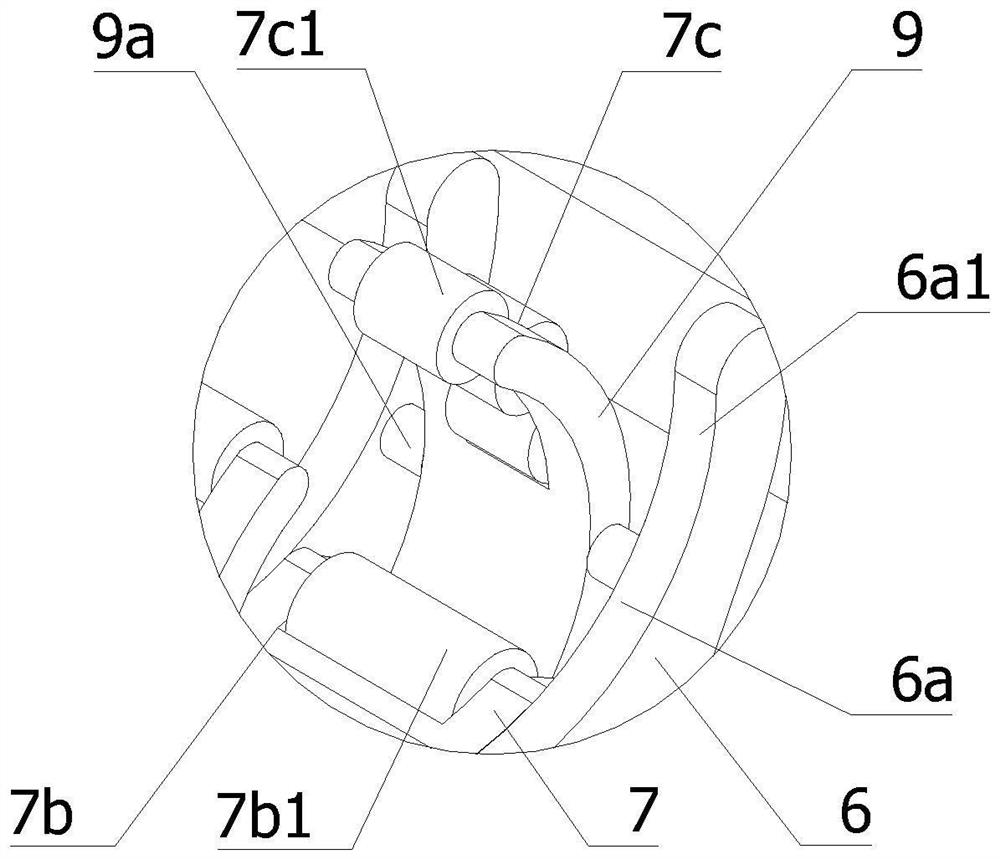

The invention relates to the technical field of automobile transmission shaft machining, in particular to an automobile transmission shaft polishing device based on intelligent automobile manufacturing, which comprises a worktable, two fixed clamping jaws, a first linear driver, a polishing roll shaft and a second linear driver, a stabilizing assembly is arranged on the workbench and comprises a first sliding groove, a placing frame, a first sliding block, a first elastic piece and a stabilizing clamping jaw. Transmission shafts with different lengths can be conveniently placed by adjusting the position of a placing frame through a first sliding groove and the placing frame, meanwhile, the situation that the transmission shafts slide out due to inertia is reduced through a supporting rod, and a first sliding block is influenced by the gravity of the transmission shafts, so that the elastic force of a first elastic piece is overcome, and the first sliding block moves downwards; the bottom end of the stable clamping jaw is hinged to the first sliding block, and the first connecting rod in the middle of the stable clamping jaw is hinged to the placing frame, so that a lever is formed, and the first sliding block drives the fixed clamping jaw to move when descending so as to stably clamp the transmission shaft on the fixed clamping jaw.

Description

technical field [0001] The invention relates to the technical field of automobile transmission shaft processing, in particular to an automobile transmission shaft grinding device based on automobile intelligent manufacturing. Background technique [0002] Existing grinding devices for automobile transmission shafts, such as a high-efficiency grinding device for processing automobile transmission shafts with a dust removal function disclosed in Patent No. CN202120582736. The part supports the bottom end of the drive shaft, so that it can be stabilized. The drive shaft is ground by the upper grinding roller, but its clamping is not stable and it needs to use multiple linear drives during the clamping process, which greatly increases the complexity of its structure. . Contents of the invention [0003] Based on this, it is necessary to provide an automobile drive shaft grinding device based on automobile intelligent manufacturing in view of the existing technical problems. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24B5/36B24B27/02B24B41/06B24B41/00B24B55/00B24B41/02

CPCB24B5/36B24B27/02B24B41/067B24B41/007B24B55/00B24B41/02

Inventor 邵彭伟

Owner 邵彭伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com