Material distribution device and method for food processing

A technology for food processing and materials, which is applied in the field of material distribution devices for food processing, can solve problems that affect food processing quality, low work efficiency, and large manpower and material resources, and achieve the effects of improving food processing quality, improving processing efficiency, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

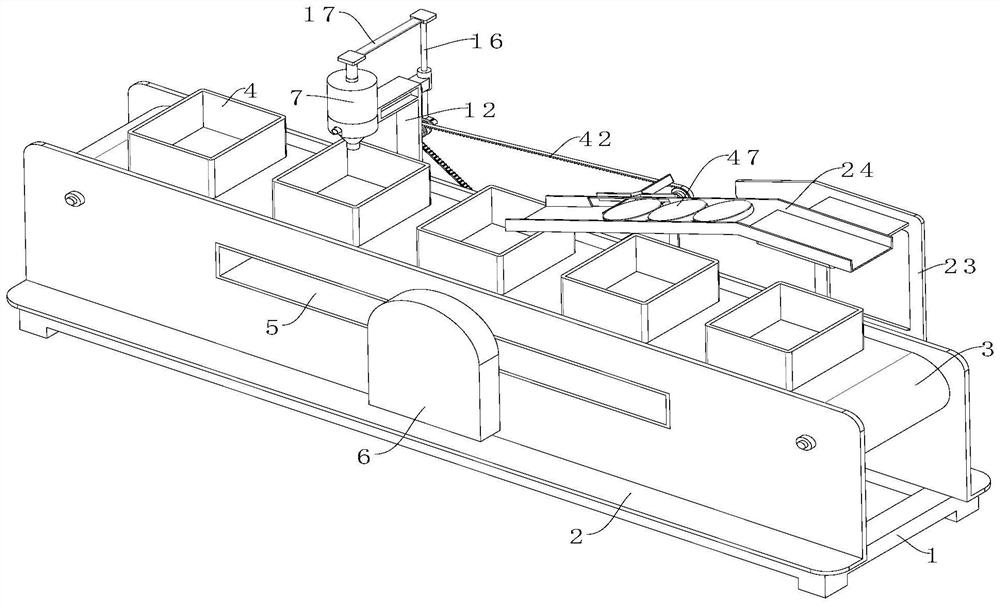

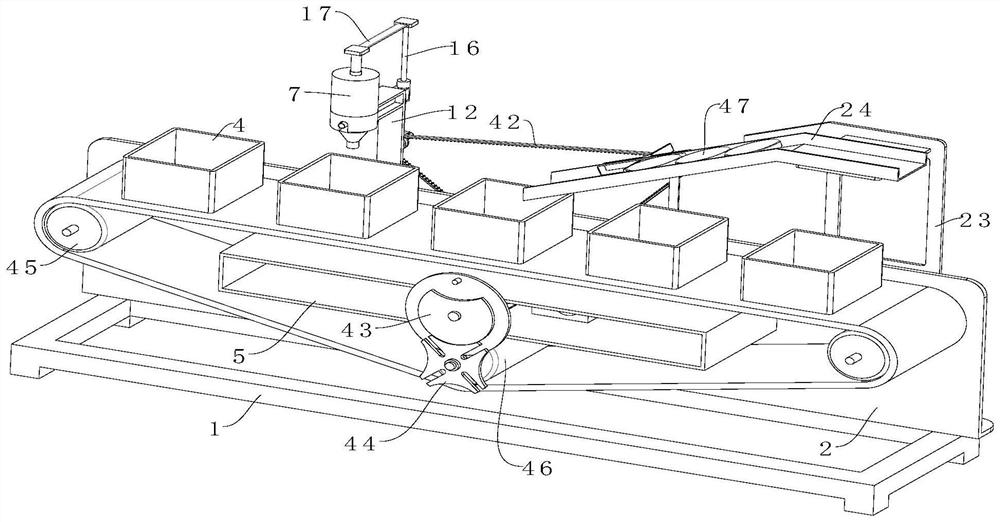

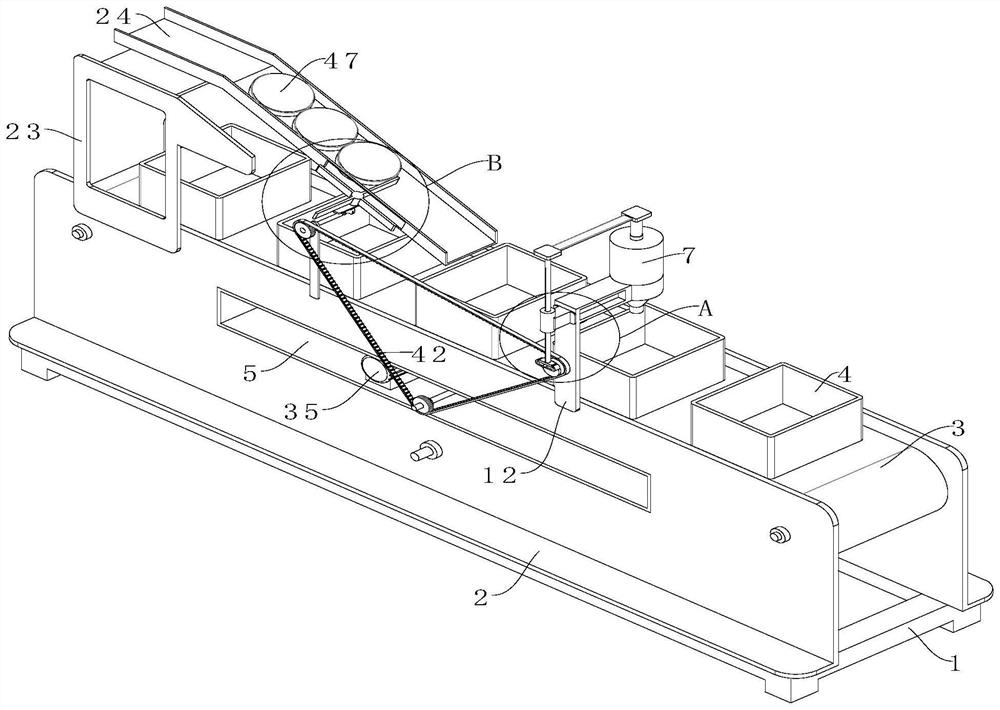

[0037] see Figure 1-Figure 10 , the technical solution provided by this embodiment is as follows:

[0038] A material distribution device for food processing, comprising a base 1, two supporting frames 2 are fixedly connected to the upper end of the base 1, and a driving roller 46 and two driven rollers 45 are rotatably connected between the two supporting frames 2, and the driving roller 46 The conveyor belt 3 is connected with the two driven rollers 45 in a driving manner. The upper side of the conveyor belt 3 is provided with a plurality of evenly distributed material boxes 4. The upper side of the material box 4 is provided with an inclined frame 24. There are a discharging assembly and a liquid dispensing assembly, an installation frame 5 is fixedly connected between the two support frames 2 , and a drive assembly is arranged in the installation frame 5 .

[0039] In the specific embodiment of the present invention, the inclined frame 24 is located on the upper side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com