Rolling device for assisting assembly of automobile door frame rubber strip

A technology of auxiliary assembly and rolling device, applied in the direction of household appliances, other household appliances, household components, etc., can solve the problems of glue strip fixation, great influence of human factors, inability to meet production rhythm, etc., to ensure consistency and save assembly effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following embodiments are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

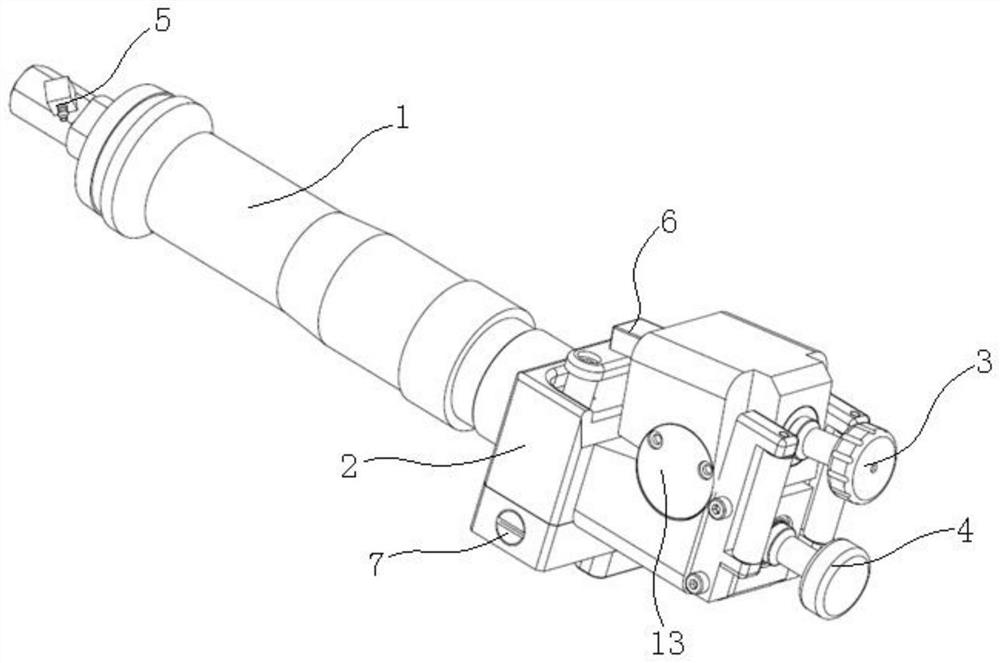

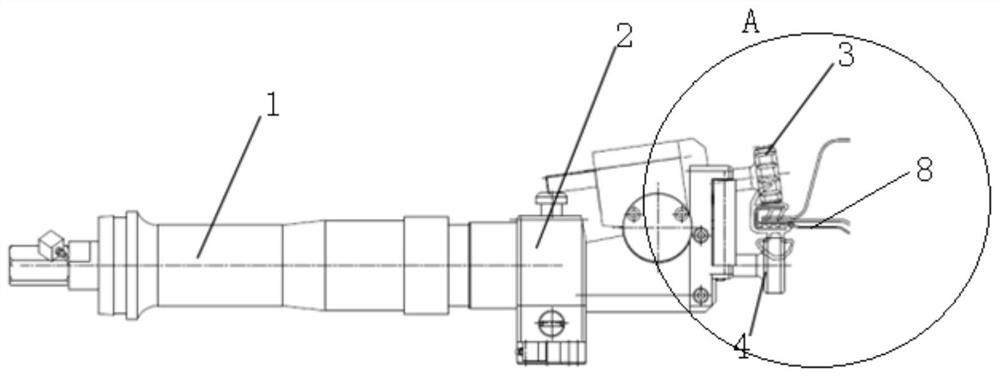

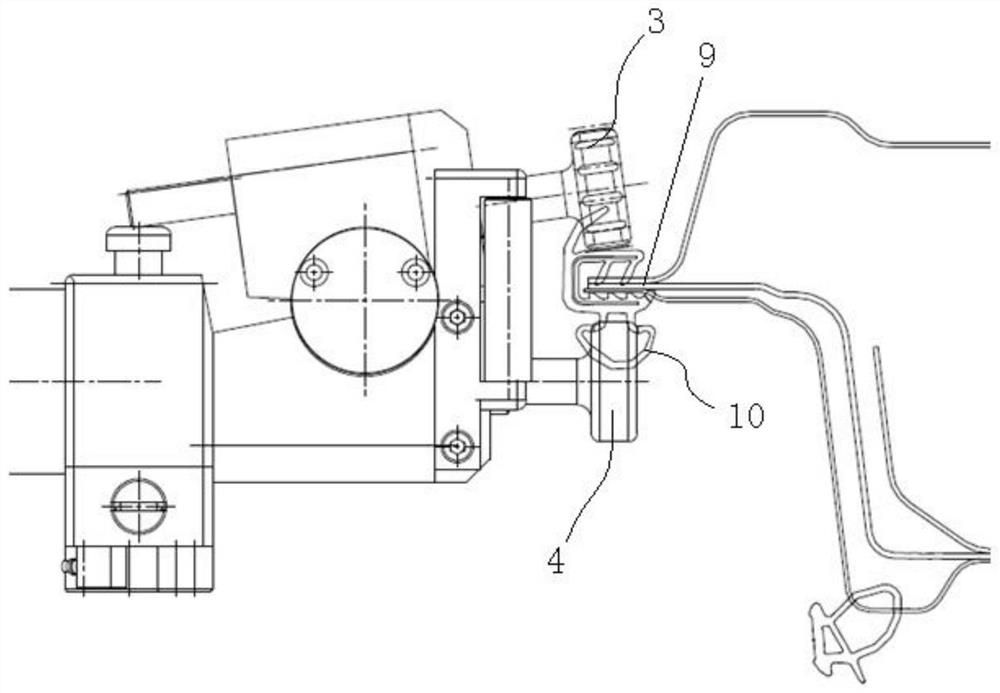

[0027] like Figure 1 to Figure 6 As shown, the present application provides a rolling device for assisting the assembly of four-door rubber strips for automobiles, including a casing, a drive shaft 1 , a pressing cylinder 2 , a drive wheel 4 and a driven wheel 3 .

[0028] In the technical solution of the present application, the casing may not be included, and the drive shaft of the present application can replace the casing, that is, the drive shaft is a pneumatic rotating device, and a drive wheel can be added before the pneumatic tightening tool, and a drive shaft is provided on the drive shaft. The shaft a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com