Eight-treasure rice pudding filling process and eight-treasure rice pudding filling machine

A filling machine and eight-treasure technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of increasing the difficulty of feeding the feeding process, the amount of feeding is small, and the feeding speed cannot be guaranteed. Efficiency and stability, avoid sticking or falling together, and avoid the effect of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

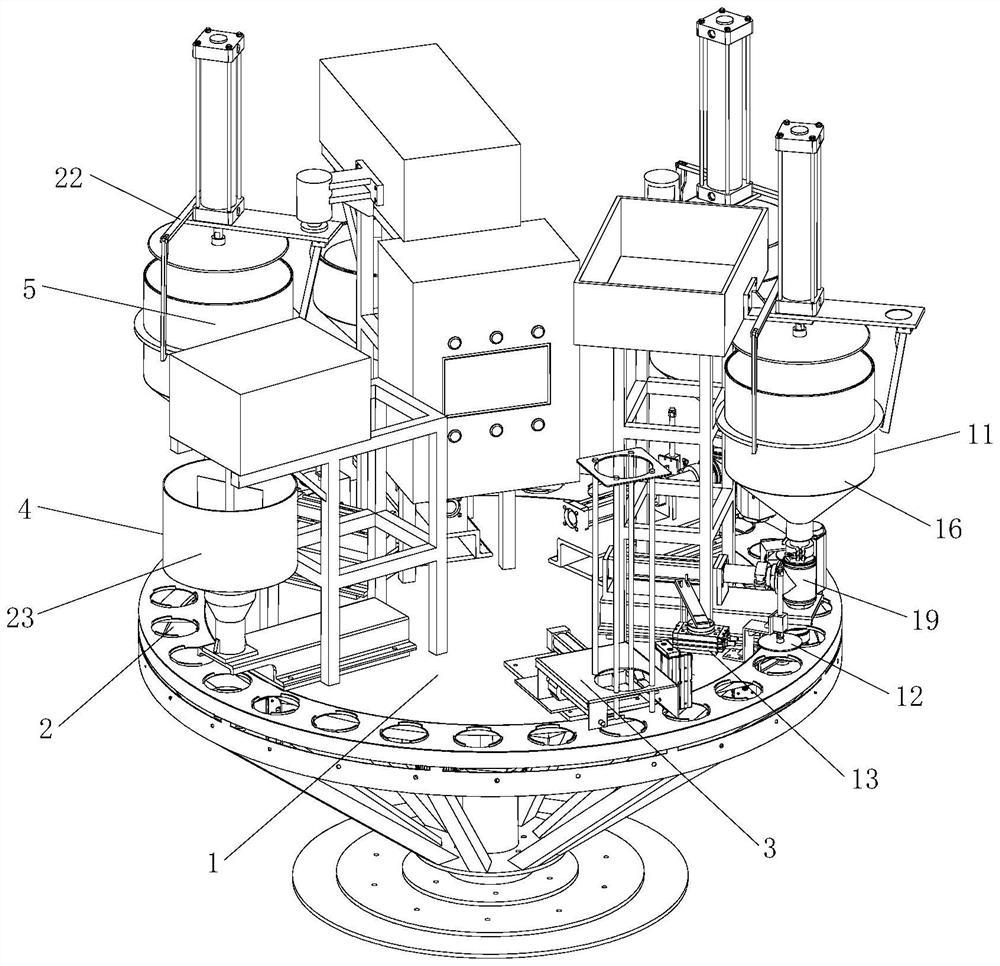

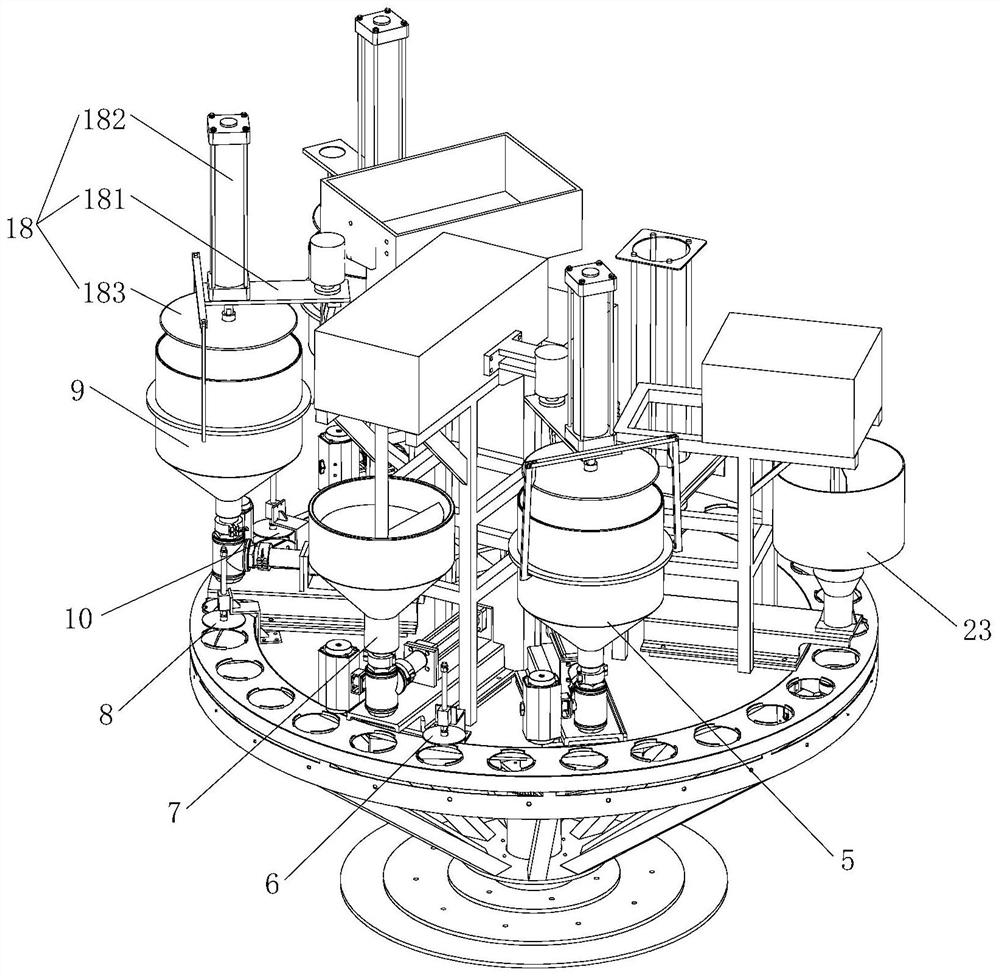

[0046] Example 1. A filling process for eight-treasure rice, comprising the following steps:

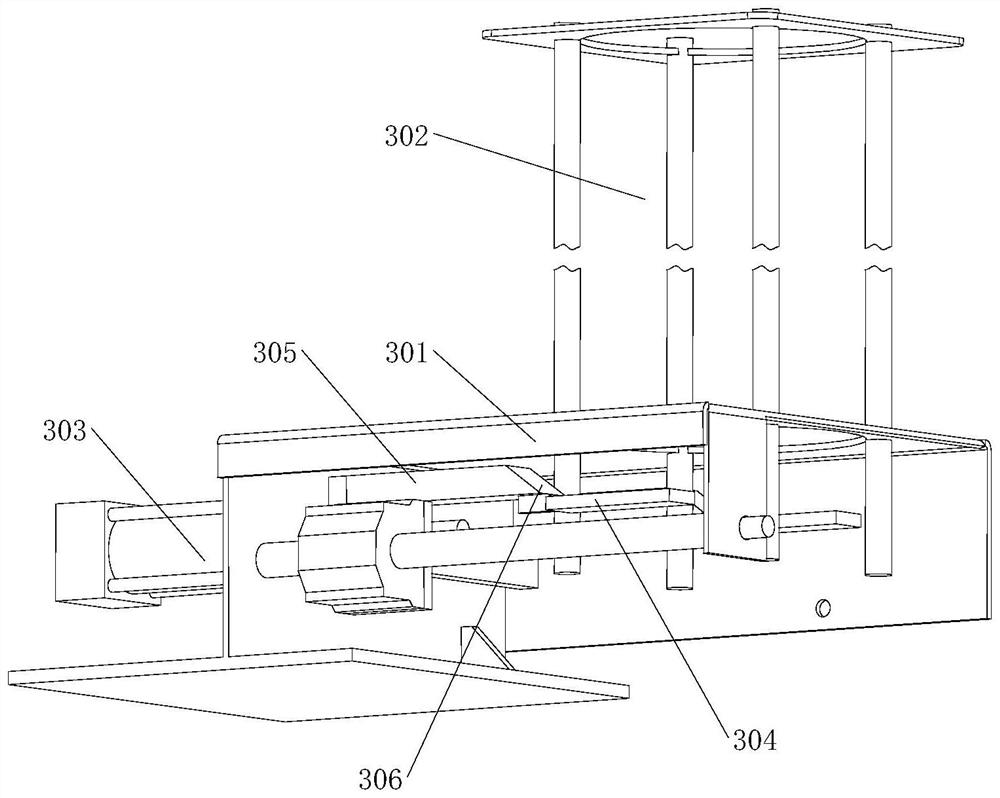

[0047] ①Separate the stacked bowls by the bowl-receiving part 3 and make them fall into the bowl-receiving grooves to obtain A bowls;

[0048] ② Put candied dates as an auxiliary material into the auxiliary material part 4, and the auxiliary material is put into the A bowl set by the auxiliary material part 4 to obtain the B bowl set;

[0049] 3. After the rice is put into the B bowl by the first lower rice part 5, it is pressed by the first pressing part 6, and the middle part of the rice forms a concave area after pressing, and the C bowl is obtained;

[0050] 4. After the bean paste filling is put into the concave area in the C bowl by the filling part 7, it is pressed by the second pressing part 8 to obtain the D bowl;

[0051] ⑤ After the rice is put into the D bowl again by the second lower rice portion 9, it is pressed by the third pressing portion 10 to obtain the E bowl; ...

Embodiment 2

[0067] Example 2. A filling process for eight-treasure rice, comprising the following steps:

[0068] ①Separate the stacked bowls by the bowl-receiving part 3 and make them fall into the bowl-receiving grooves to obtain A bowls;

[0069] ② Put candied dates as an auxiliary material into the auxiliary material part 4, and the auxiliary material is put into the A bowl set by the auxiliary material part 4 to obtain the B bowl set;

[0070] 3. After the rice is put into the B bowl by the first lower rice part 5, it is pressed by the first pressing part 6, and the middle part of the rice forms a concave area after pressing, and the C bowl is obtained;

[0071] 4. After the bean paste filling is put into the concave area in the C bowl by the filling part 7, it is pressed by the second pressing part 8 to obtain the D bowl;

[0072] ⑤ After the rice is put into the D bowl again by the second lower rice portion 9, it is pressed by the third pressing portion 10 to obtain the E bowl;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com