Disassembly-free multifunctional assembling trolley suitable for fully-assembled subway station

A multi-functional technology for subway stations, applied in construction, artificial islands, infrastructure engineering, etc., can solve the problems of prefabricated parts assembly errors, affecting construction quality, poor adjustment accuracy, etc., to facilitate movement and adjustment, and improve overall construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

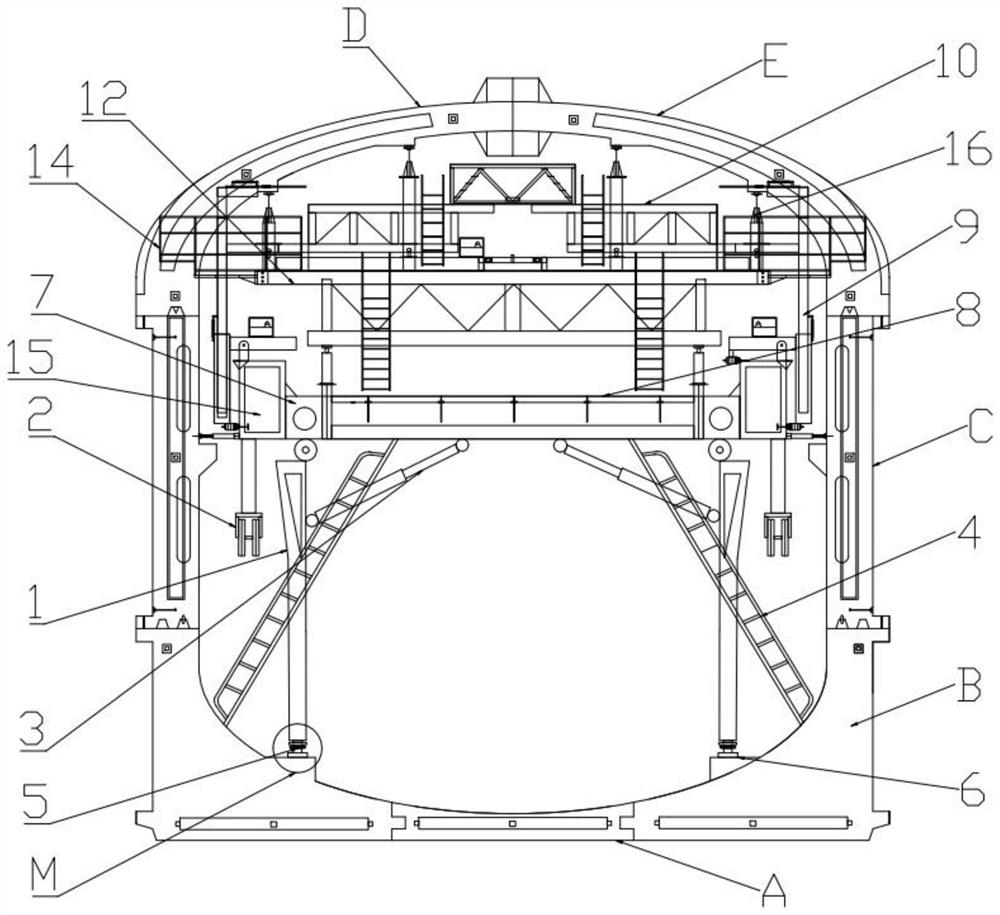

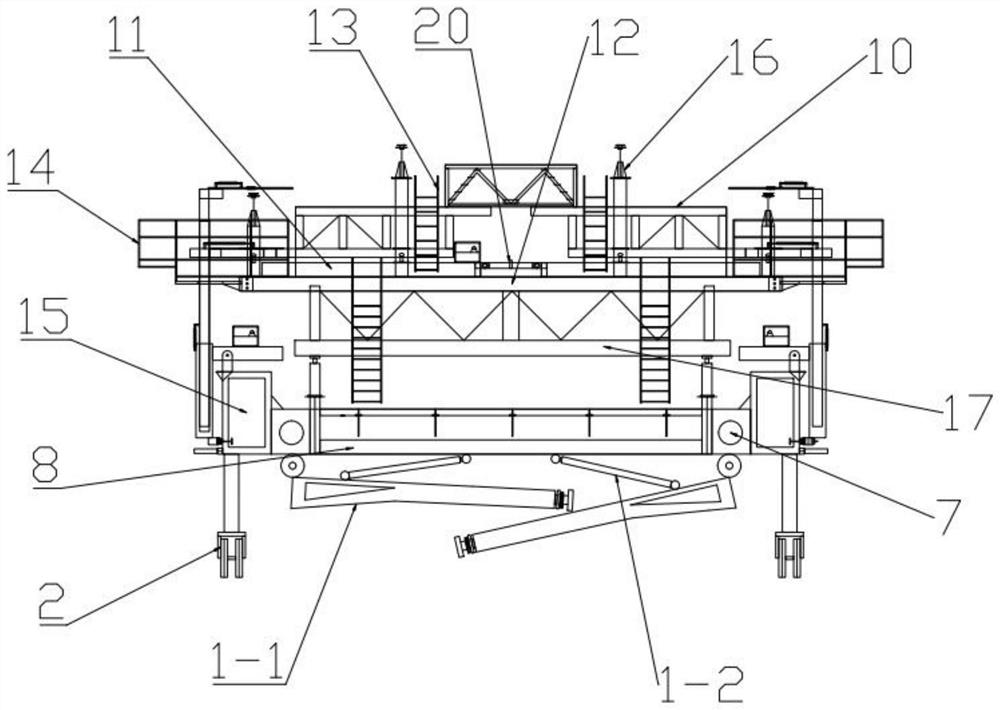

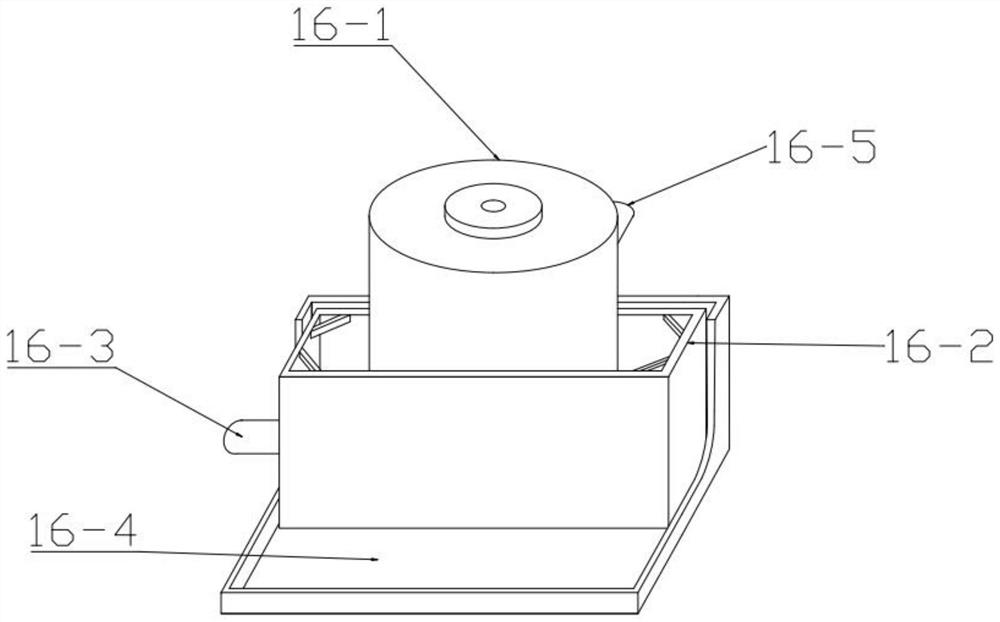

[0041] Specific implementation one: Combining Figure 1 to Figure 9 As shown, the present invention provides a disassembly-free multifunctional assembled trolley suitable for a fully assembled subway station, including a running mechanism 5, a frame, an adjustable hanger 9 and a top assembly frame;

[0042] The frame includes a working platform 8 and frame longitudinal beams 7 on both sides. A number of foldable legs 1 and a number of universal wheels 2 are evenly arranged on the lower end surface of the frame longitudinal beam 7 on each side. The leg 1 is hinged with the frame longitudinal beam 7, and the foldable outrigger 1 is connected with the lower end surface of the working platform 8 through the outrigger hydraulic telescopic rod 3, which is used to store the foldable outrigger 1 under the working platform 8, and the platform When the car is placed on the plane, it can walk through the universal wheel 2, which is convenient for the movement and transportation of the wh...

specific Embodiment approach 2

[0051] Specific implementation two: combination Image 6 As shown, the universal wheel 2 is located outside the foldable outrigger 1 to avoid affecting the folding of the foldable outrigger 1 . Other combinations and connection relationships of this embodiment are the same as those of the specific embodiment one.

specific Embodiment approach 3

[0052] Specific implementation three: combining Figure 7 As shown, it also includes a walking ladder 23, the working platform 8 is provided with a walking ladder placement port 21, one side of the walking ladder placement port 21 is provided with a walking ladder fixing member 22, and one end of the walking ladder 23 is provided with a fixing hook 24 , the walking ladder 23 is connected with the working platform 8 through the fixing hook 24 and the walking ladder fixing part 22. When the trolley is used in the deep foundation pit, the walking ladder 23 can be lowered to the B prefabricated part for material handling, When the foldable outriggers 2 are retracted, the walking ladder 23 can be retracted to realize the overall displacement of the trolley. Other combinations and connection relationships of this embodiment are the same as those of the second specific embodiment.

[0053] Preferably, the walking ladder 23 is an electric escalator or a crawling ladder, and the elect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap