Connecting pipe sealing measuring device for pressure-bearing special equipment

A technology of special equipment and measuring device, which is applied in the direction of measuring device, using stable tension/pressure to test the strength and strength characteristics of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

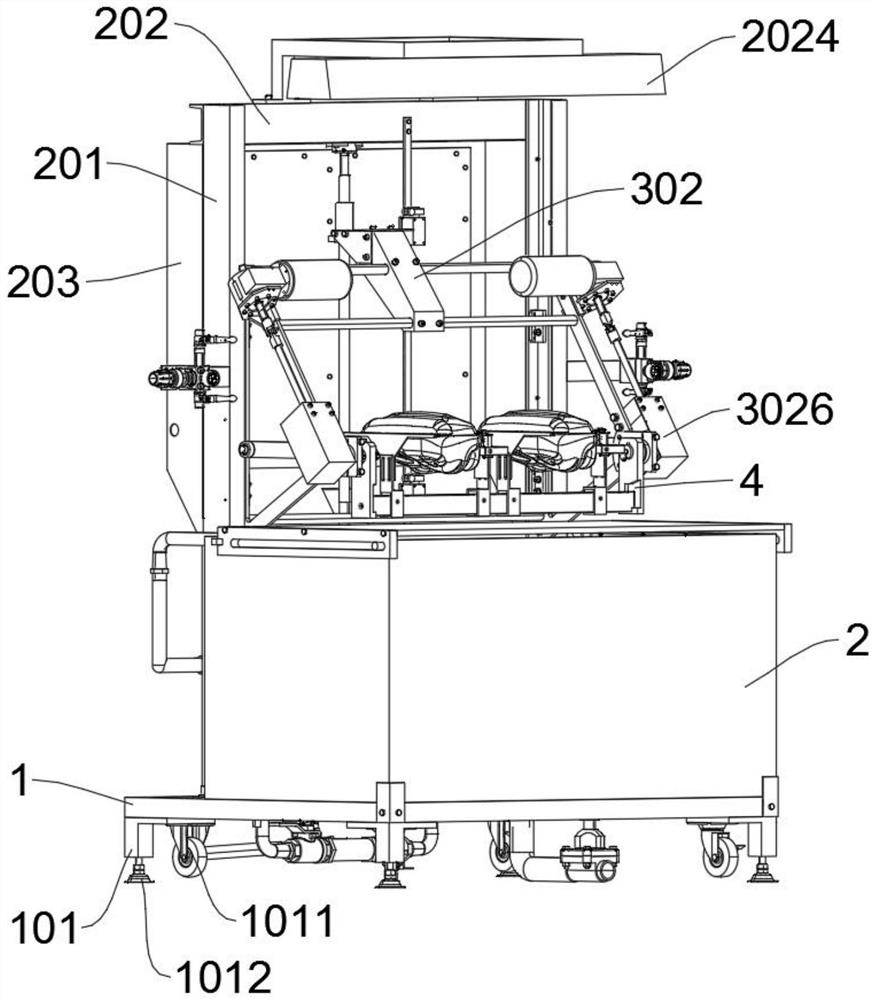

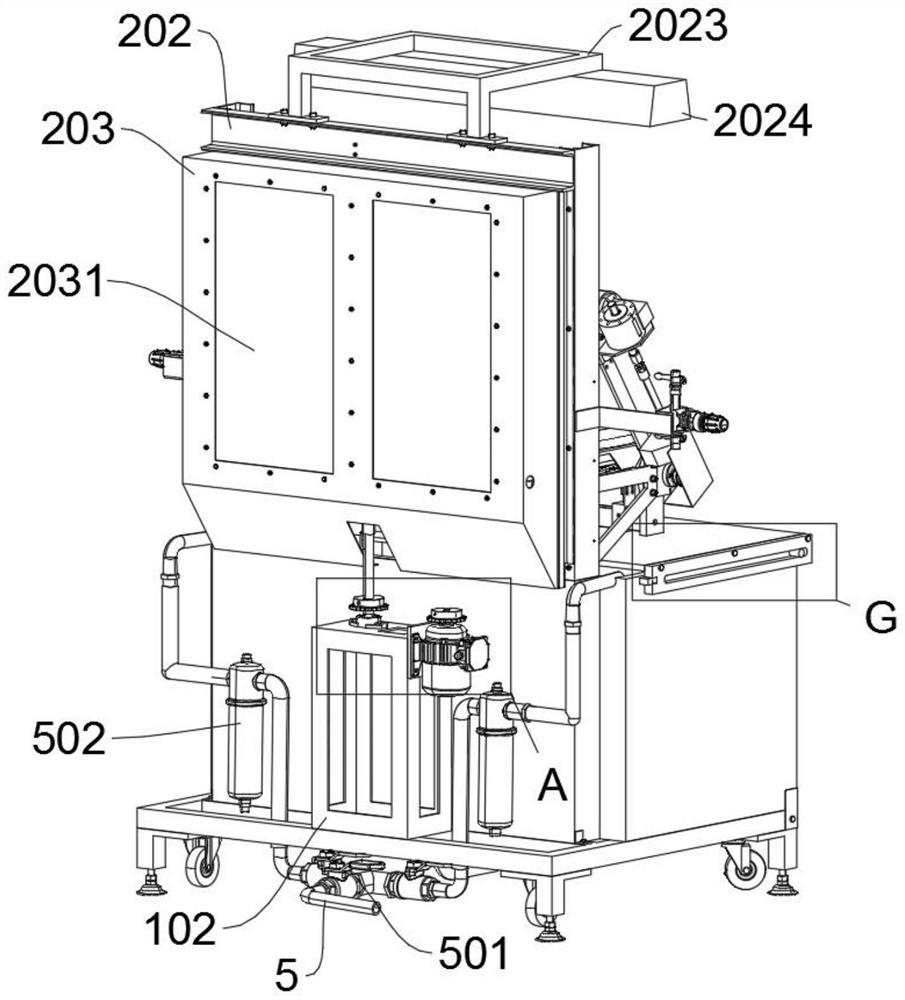

[0036] Example: please refer to Figure 1 to Figure 12 :

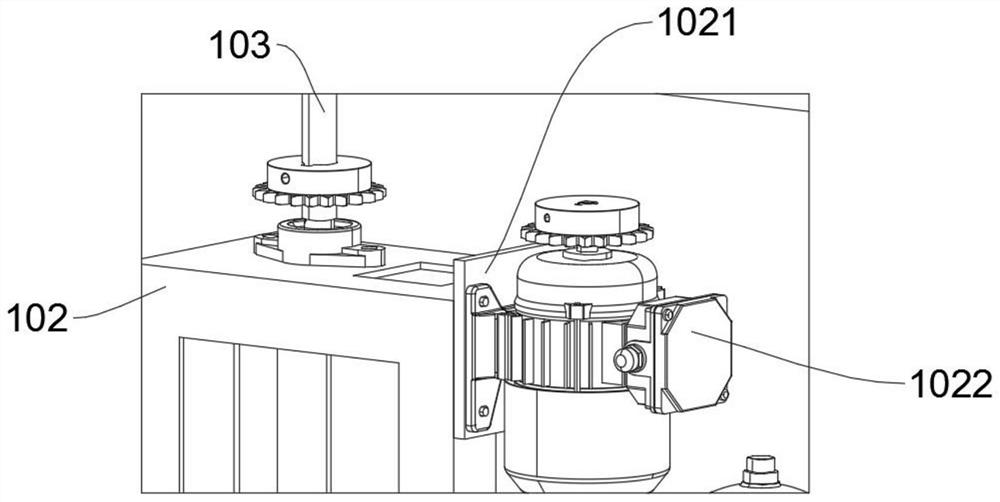

[0037]The present invention provides a nozzle seal measuring device for pressure-bearing special equipment, comprising: a base frame 1, four sets of mounting plates 101 are fixedly installed at the lower end of the base frame 1, and the bolts on the mounting plate 101 are installed with moving wheels 1011 and supporting feet 1012, a frame 102 is installed on the bottom frame 1, a vertical plate 1021 is installed on the frame 102 with bolts, a No. 1 motor 1022 is installed on the vertical plate 1021 with bolts, a sprocket is installed on the rotating shaft of the No. 1 motor 1022, and the upper end of the frame 102 is installed with bolts There is a bearing seat; box body 2, the lower end of box body 2 is provided with a drain pipe, a drain valve is installed on the drain pipe, box body 2 is installed on the chassis 1, and two sets of support rods are fixedly installed at the rear end of box body 2 201, two sets of hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com