Multi-contact mechanical spot welding equipment

A spot welding equipment, multi-contact technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve problems such as easy damage to the user's body, and achieve the effect of high applicability, simple use, and improved operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

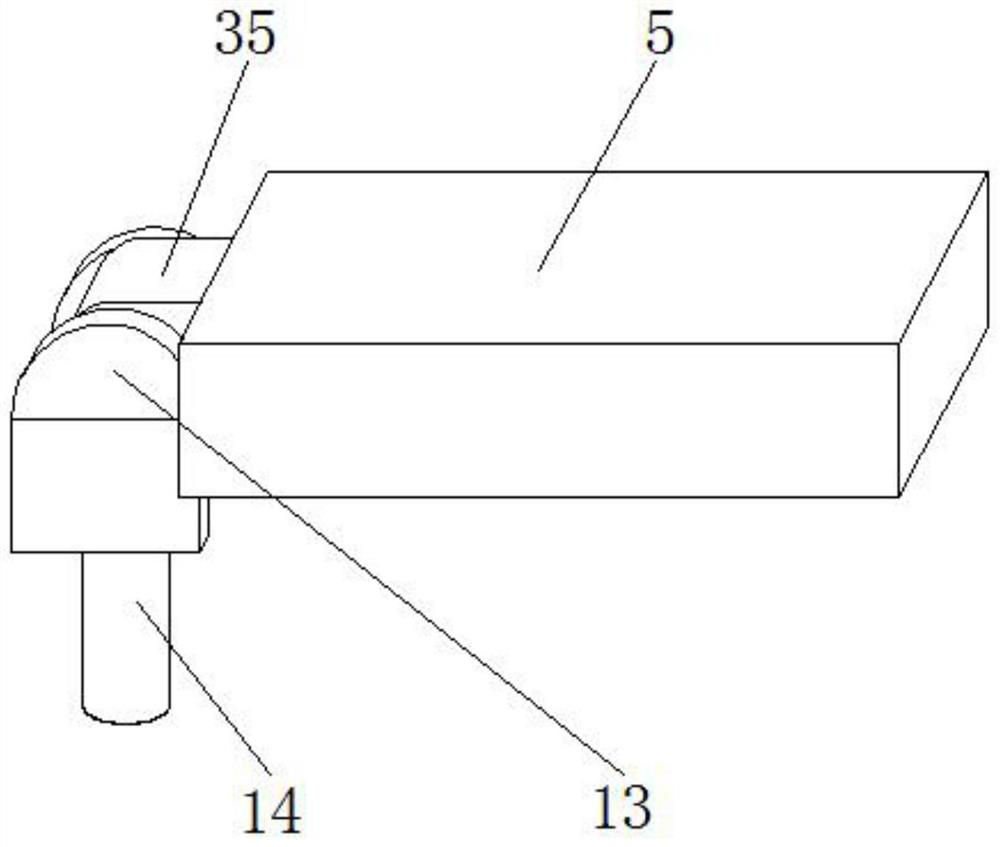

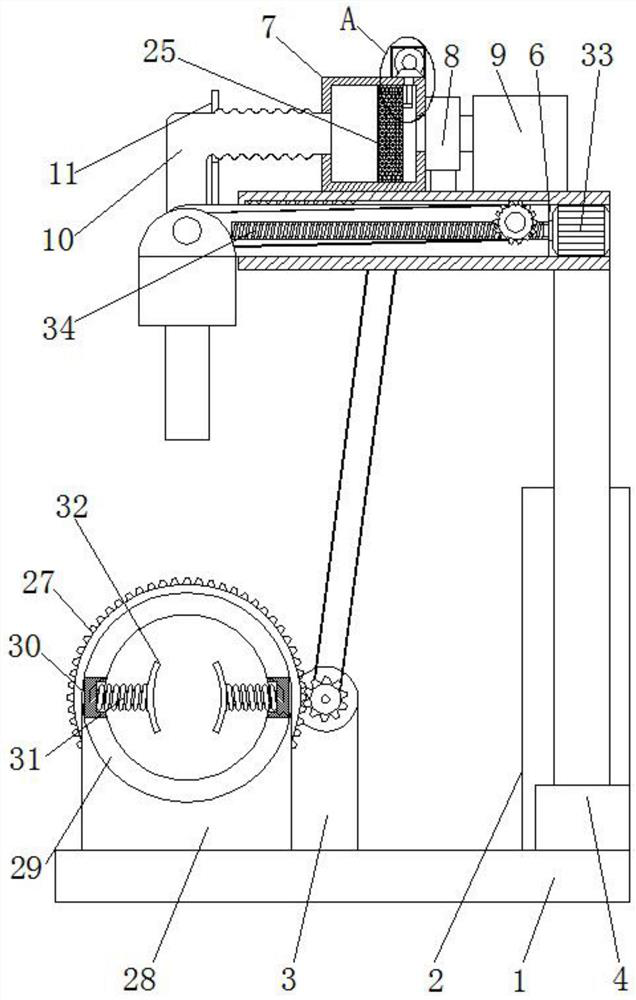

[0027] refer to Figure 1-4 , a multi-contact mechanical spot welding equipment, including a base 1, a vertical box 2 is arranged on the base 1, a motor base 3 is arranged on the base 1, a cylinder 4 is arranged in the vertical box 2, and the telescopic rod of the cylinder 4 is fixedly installed There is a horizontal plate 5, a horizontal slot 6 is opened in the horizontal plate 5, a storage box 7 is arranged on the horizontal plate 5, a fan 8 is arranged on one side of the storage box 7, an adsorption box 9 is arranged on the fan 8, and one side of the storage box 7 is provided. A stack tube 10 is arranged on the side, a first motor 15 is arranged on the motor base 3, a rotating rod 16 is fixedly installed on the output shaft of the first motor 15, a filter mechanism is arranged on the horizontal plate 5, and a clamping mechanism is arranged on the base 1 , a second motor 33 is arranged in the horizontal groove 6, a threaded rod 34 is fixedly installed on the output shaft of ...

Embodiment 2

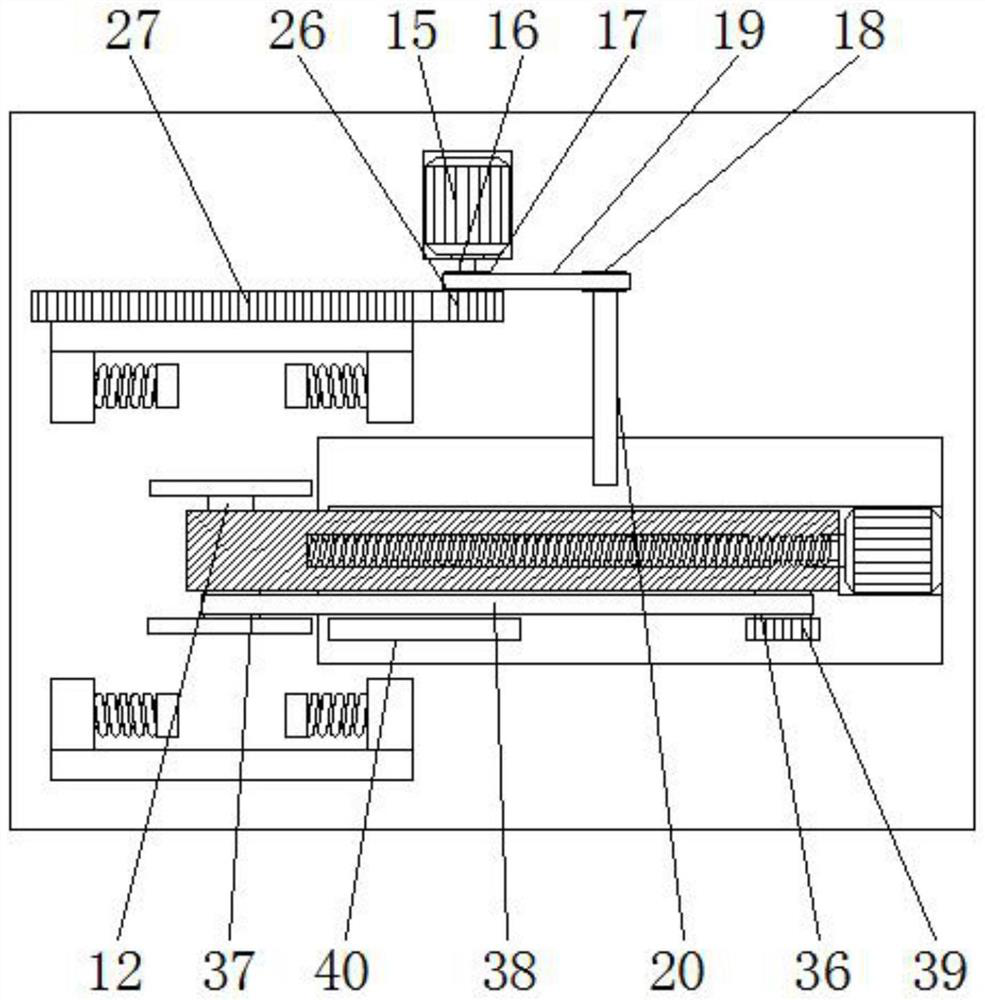

[0039] refer to Figure 5-6 , the difference from the first embodiment is that the filter mechanism includes a first pulley 17, the first pulley 17 is fixedly connected with the rotating rod 16, the rotating rod 20 is rotatably installed on the storage box 7, and the rotating rod 20 is fixedly installed with a second belt The same first belt 19 is installed on the pulley 18, the first pulley 17 and the second pulley 18, the half gear 41 is fixedly installed on the rotating rod 20, and the storage box 7 is provided with a straight rail, which is slidably installed on the straight rail. There is a toothed frame 42 , the toothed frame 42 is engaged with the half gear 41 , the storage box 7 is provided with a filter screen 25 , and the filter screen 25 and the toothed frame 42 cooperate with each other.

[0040] Working principle: when spot welding two round pipes, clamp the two round pipes between the four clamp plates 32, and make the two round pipes connect, under the cooperati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com