Test bench for water immersion performance test of precision rolling bearing

A technology for rolling bearings and test benches, which is used in mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of draft depth of bearing grease moisture content, difficult monitoring of testing time, difficult bearing performance testing, and impact on bearing testing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

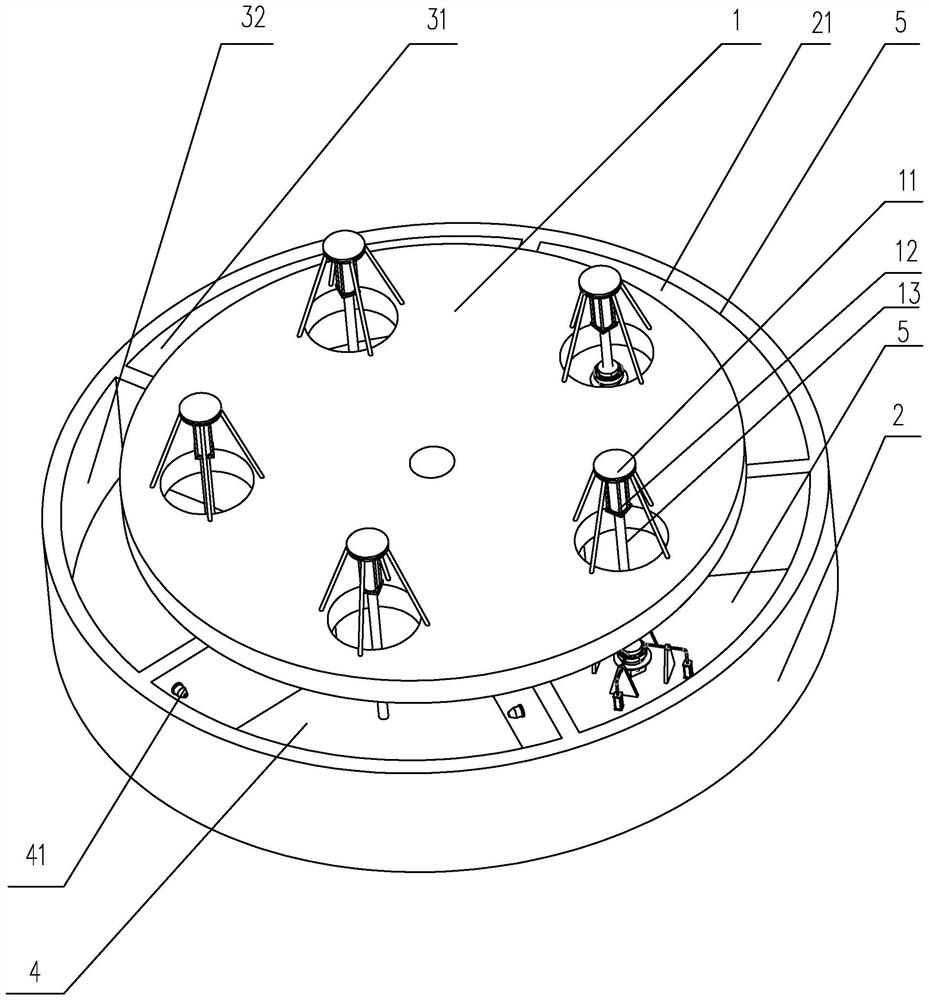

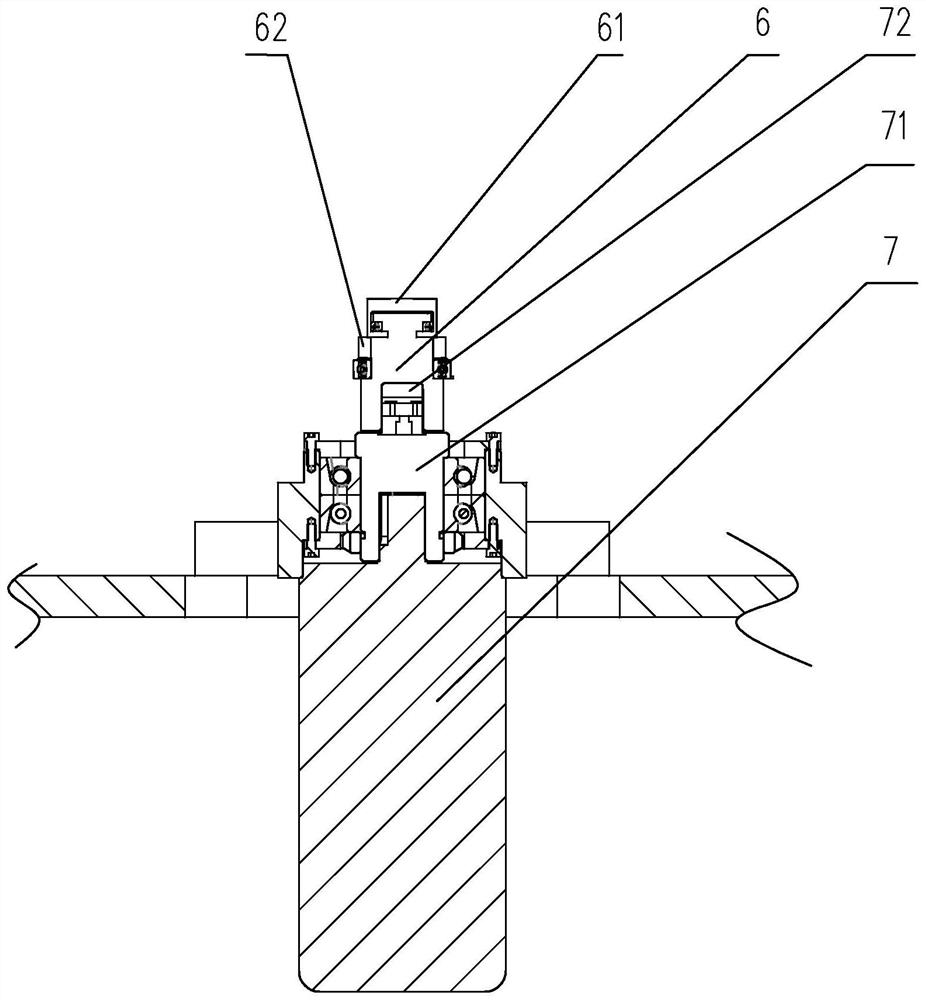

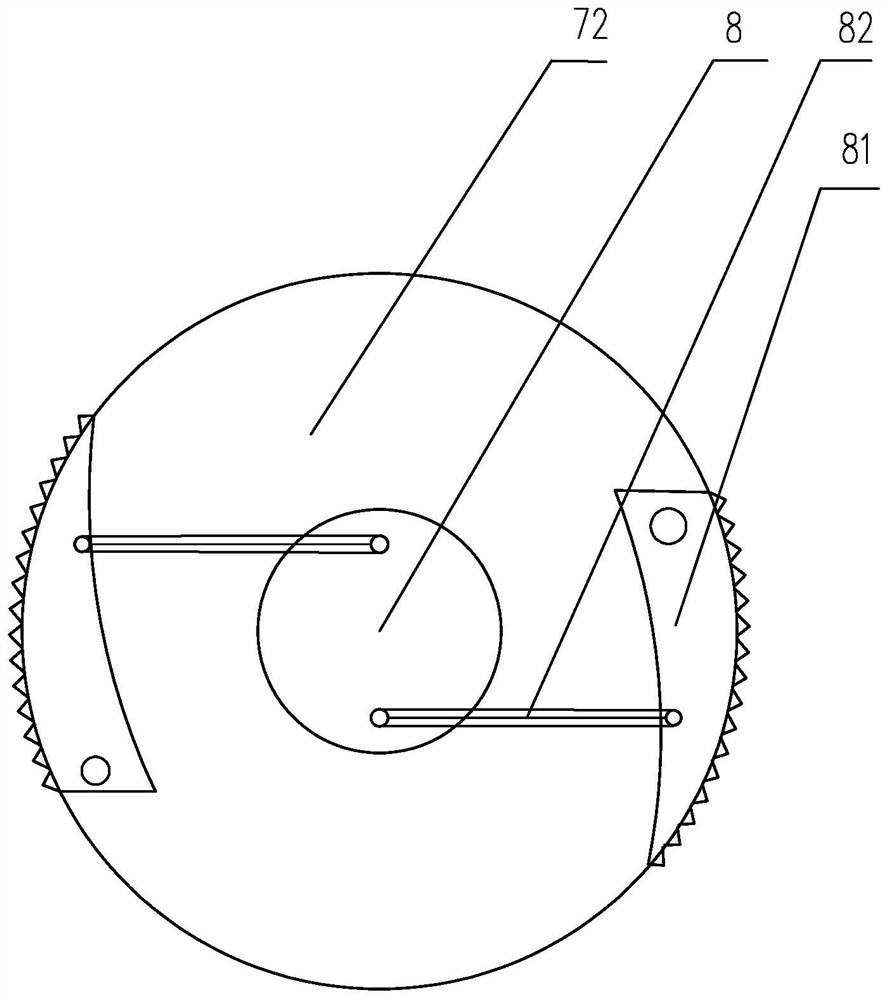

[0022] An example of the test bench used for the water immersion performance test of the precision rolling bearing of the present invention is as follows: Figure 1 to Figure 4 Shown: It includes a test table 2 and a rotating work plate 1, the test table 2 is arranged along the circumferential direction of the work plate 1, the work plate 1 is provided with a number of work grooves, and the work groove is provided with a lifting frame 11. The lifting frame 11 is provided with a lifting rod 13 and a first driving member 12 for driving the lifting rod 13 to slide in the height direction. There are electromagnets, and the test table 2 is provided with a placement area, a soaking area, a high-speed flushing area 4 and a rotating test area 5 in turn. There is a mounting seat 6, the mounting seat 6 is provided with a mounting groove for matching with the inner ring of the bearing to be tested, one end of the mounting seat 6 is rotatably provided with an armature seat 61 for matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com