A method for assembling heat exchange tube bundles for closed cooling towers

A technology of closed cooling towers and heat exchange tube bundles, which is applied to heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., which can solve problems such as high cost, difficult installation, and difficult processing, and prevent vibration and deformation , Reduce processing difficulty, reduce processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] Referring to the accompanying drawings, the specific implementation is as follows:

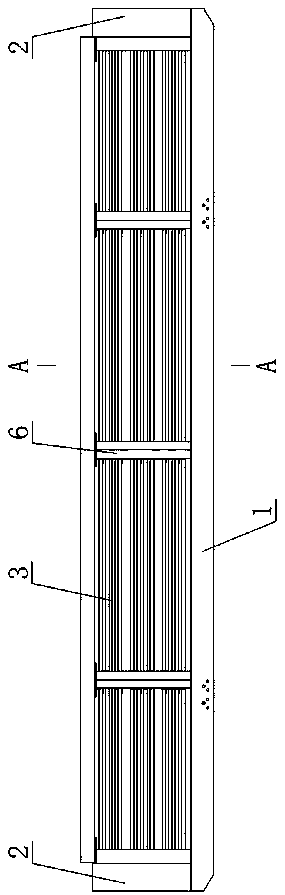

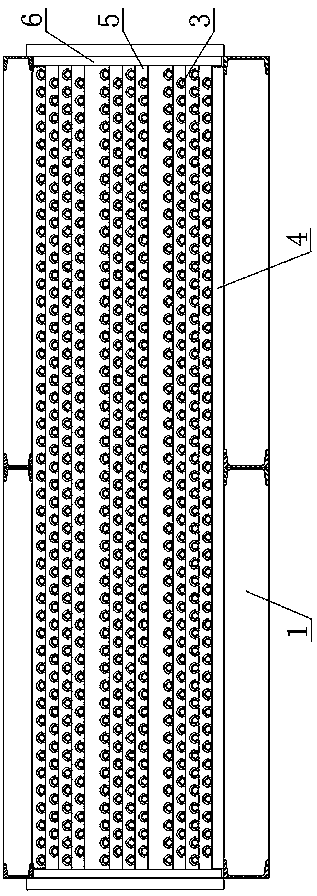

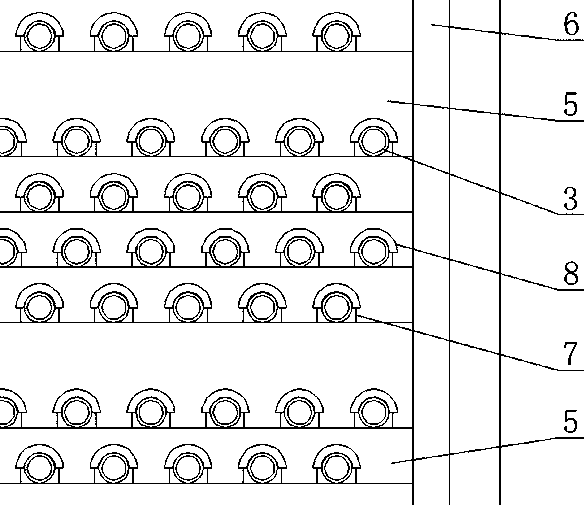

[0033] An assembly method for a heat exchange tube bundle of a closed cooling tower, the heat exchange tube bundle includes a tube bundle frame 1, two tube boxes 2 and a plurality of heat exchange tubes 3, and the two tube boxes 2 are fixedly installed on the tube bundle The two ends of the frame 1 and the two ends of the heat exchange tubes 3 are respectively fixedly installed in the two tube boxes 2, and the plurality of heat exchange tubes 3 are arranged horizontally and parallel to each other, and the plurality of heat exchange tubes 3 are divided into a layer, each layer is a row of heat exchange tubes 3 arranged at intervals at the same height position, and b split-type support clamps for supporting all heat exchange tubes 3 at the same time are provided between the two tube boxes 2, when b > At 1 o'clock, the b split-type support clamps are distributed at intervals along the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com