Flame-retardant wear-resistant cable and preparation method thereof

A kind of cable and wear-resistant sleeve technology, which is used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problem of cable surface damage, poor flame-retardant and wear-resistant effects of cables, reducing wear-resistant and flame-retardant effects, etc. problems, to achieve the effect of improving service life, facilitating observation, and avoiding internal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

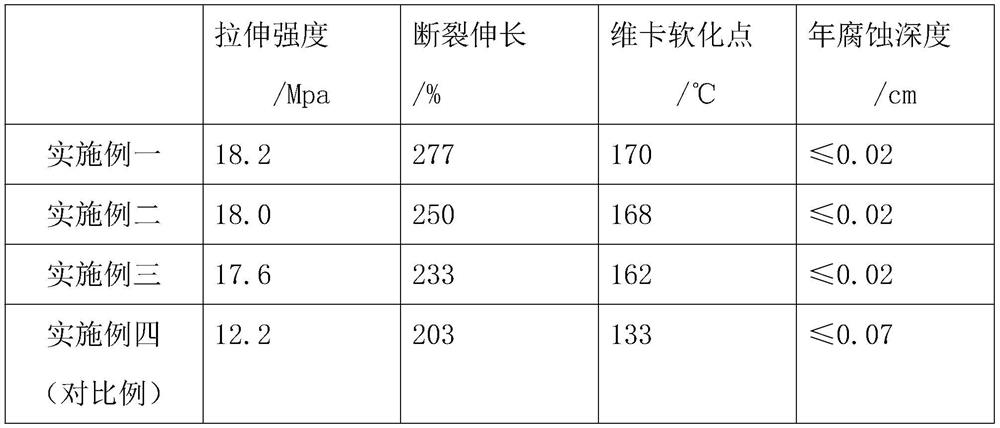

Embodiment 1

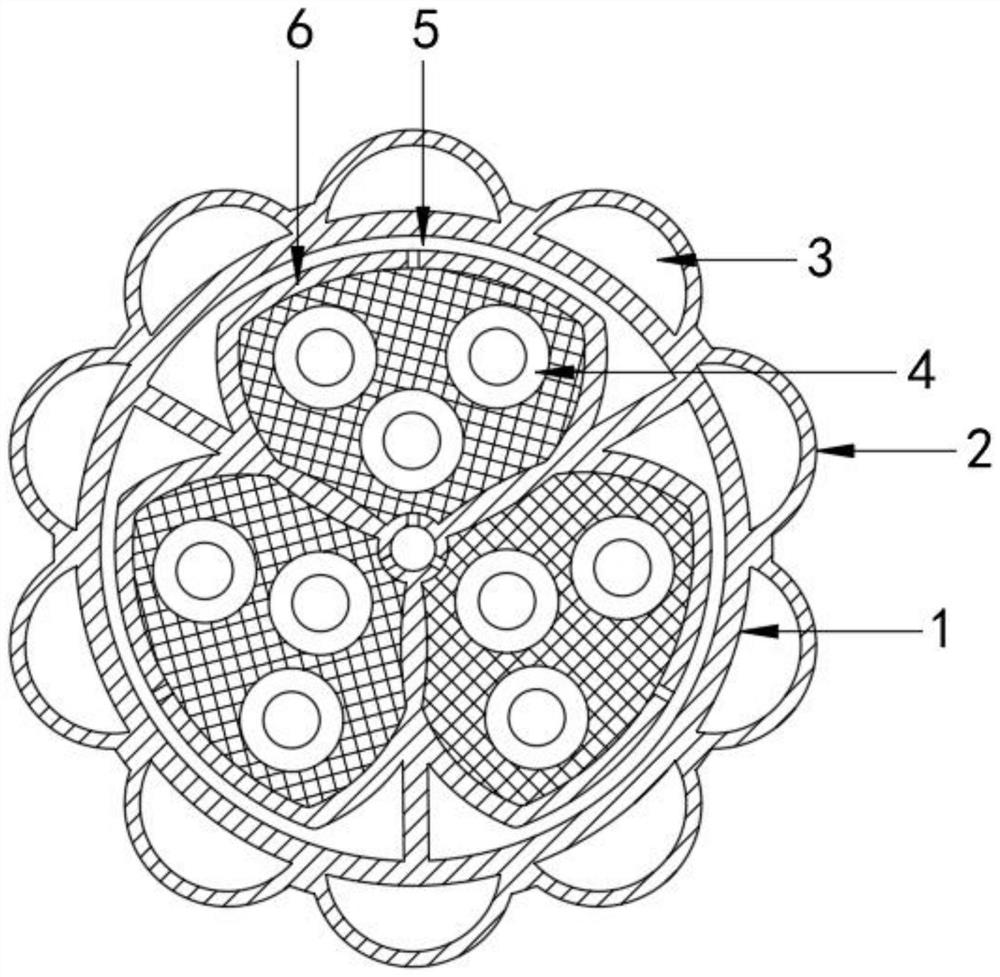

[0023] see figure 1 , the present invention provides a technical solution: a flame-retardant wear-resistant cable, comprising: a cable core 4 and a flame-retardant wear-resistant sleeve, the flame-retardant wear-resistant sleeve includes an insulating layer arranged outside the cable core 4, wrapped in a gas The reinforcement layer 6 outside the gel insulating layer is wrapped around the sheath layer 1 outside the reinforcement layer 6. A flame retardant cavity 5 is formed between the sheath layer 1 and the reinforcement layer 6, and the flame retardant cavity 5 is filled with Flame retardant, ten wear-resistant layers 2 distributed in an annular shape are evenly arranged on the outer wall of the jacket layer 1, and the wear-resistant layers 2 have an arc structure and a wear-resistant layer 2 is formed between the inside and the jacket layer 1. Cavity 3, the interior of the wear-resistant cavity 3 is filled with high ignition point quick-drying glue;

[0024] The flame-retar...

Embodiment 2

[0037] A flame-retardant and wear-resistant cable, comprising: a cable core 4 and a flame-retardant wear-resistant sleeve, the flame-retardant wear-resistant sleeve includes an insulating layer arranged outside the cable core 4, and a reinforcing layer 6 wrapped around the aerogel insulating layer , the jacket layer 1 wrapped around the reinforcement layer 6, a flame retardant cavity 5 is formed between the jacket layer 1 and the reinforcement layer 6, the flame retardant cavity 5 is filled with a flame retardant, and the jacket layer Ten wear-resistant layers 2 distributed in an annular shape are evenly arranged on the outer wall of the 1. The wear-resistant layers 2 have an arc-shaped structure and a wear-resistant cavity 3 is formed between the inside and the sheath layer 1. The wear-resistant cavity 3 The interior is filled with high flash point quick-drying glue;

[0038]The flame-retardant wear-resistant cover includes the following components: 40 parts of nitrile rubber...

Embodiment 3

[0051] A flame-retardant and wear-resistant cable, comprising: a cable core 4 and a flame-retardant wear-resistant sleeve, the flame-retardant wear-resistant sleeve includes an insulating layer arranged outside the cable core 4, and a reinforcing layer 6 wrapped around the aerogel insulating layer , the jacket layer 1 wrapped around the reinforcement layer 6, a flame retardant cavity 5 is formed between the jacket layer 1 and the reinforcement layer 6, the flame retardant cavity 5 is filled with a flame retardant, and the jacket layer Ten wear-resistant layers 2 distributed in an annular shape are evenly arranged on the outer wall of the 1. The wear-resistant layers 2 have an arc-shaped structure and a wear-resistant cavity 3 is formed between the inside and the sheath layer 1. The wear-resistant cavity 3 The interior is filled with high flash point quick-drying glue;

[0052] The flame-retardant wear-resistant cover comprises the following components: 50 parts of nitrile rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com