100s mercerized cotton laza knitted fabric shirt prepared from seamless glue and manufacturing process of 100s mercerized cotton laza knitted fabric shirt

A production process and technology of knitted fabrics, applied in the field of shirt production, can solve the problems of inability to reflect the exquisite workmanship of shirts, broken lines of shirts, easy deformation, etc., and achieve the effects of high fastness, fine workmanship and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment is a manufacturing process of using seamless glue to prepare a 100s mercerized cotton pull frame knitted fabric shirt, and the manufacturing process includes the following steps:

[0032] (a) processing high elastic fabrics into mercerized cotton pull frame knitted fabrics;

[0033] (b) Cut the mercerized cotton pull frame knitted fabric according to the shirt template, and make each part of the shirt;

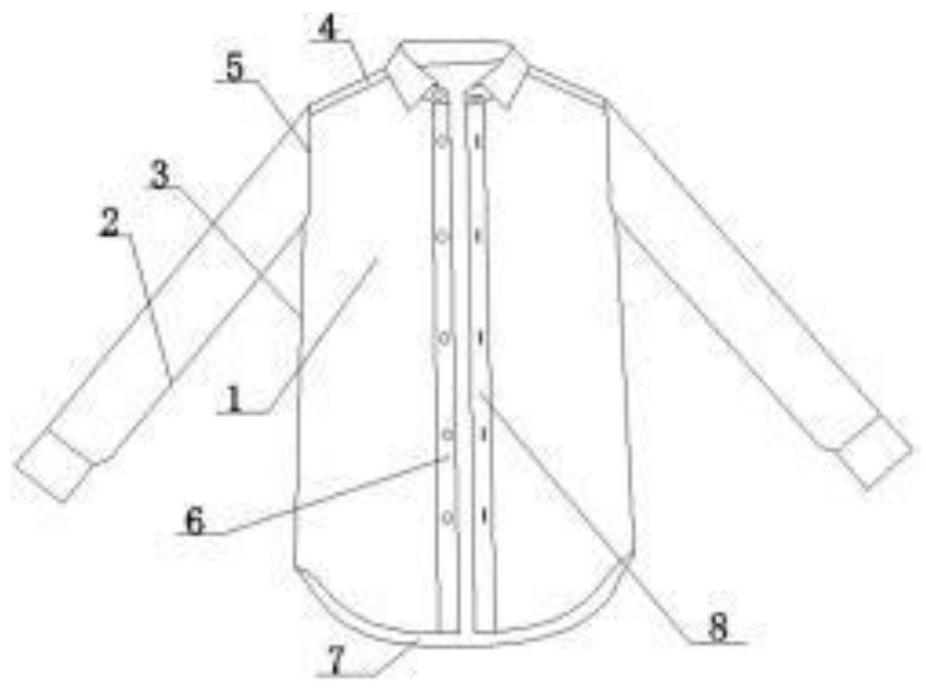

[0034] (c) Cut the elastic lining according to the size of the splicing part of each part, wherein the splicing part of each part of the shirt is as follows figure 1 As shown, the width of the elastic lining corresponding to the side seam 3, the sleeve seam 2, the upper placket 8, the lower placket 6 and the bottom edge 7 of the shirt 1 is 0.5cm; The width of the corresponding elastic lining is 1cm;

[0035] (d) Adhering the elastic lining to the corresponding splicing part with an adhesive, then ironing the splicing part, and then pressing the ...

Embodiment 2

[0038] The present embodiment is a manufacturing process of using seamless glue to prepare a 100s mercerized cotton pull frame knitted fabric shirt, and the manufacturing process includes the following steps:

[0039] (a) processing high elastic fabrics into mercerized cotton pull frame knitted fabrics;

[0040] (b) Cut the mercerized cotton pull frame knitted fabric according to the shirt template, and make each part of the shirt;

[0041] (c) Cut the elastic lining according to the size of the splicing part of each part, wherein the width of the elastic lining corresponding to the side seam, sleeve seam, upper placket, lower placket and bottom edge of the shirt is 1cm; the shoulder seam of the shirt The width of the elastic lining corresponding to the sleeve seam is 1.4cm;

[0042] (d) Adhering the elastic lining to the corresponding splicing part with an adhesive, then ironing the splicing part, and then pressing the elastic lining with a gluing machine, wherein the contro...

Embodiment 3

[0046] The present embodiment is a manufacturing process of using seamless glue to prepare a 100s mercerized cotton pull frame knitted fabric shirt, and the manufacturing process includes the following steps:

[0047] (a) processing high elastic fabrics into mercerized cotton pull frame knitted fabrics;

[0048] (b) Cut the mercerized cotton pull frame knitted fabric according to the shirt template, and make each part of the shirt;

[0049] (c) Cut the elastic lining according to the size of the splicing part of each part, wherein the width of the elastic lining corresponding to the side seam, sleeve seam, upper placket, lower placket and bottom edge of the shirt is 0.8cm; The width of the elastic lining corresponding to the seam and the sleeve seam is 1.2cm;

[0050] (d) Adhering the elastic lining to the corresponding splicing part with an adhesive, then ironing the splicing part, and then pressing the elastic lining with a gluing machine, wherein the control pressure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com