3D printing device capable of achieving stable feeding

A printing device and 3D printing technology, applied in manufacturing auxiliary devices, 3D object support structures, manufacturing tools, etc., can solve the problems of wasting processing time, poor applicability of printing devices, and inability to stably input materials, so as to avoid wasteful processing Time, the effect of improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

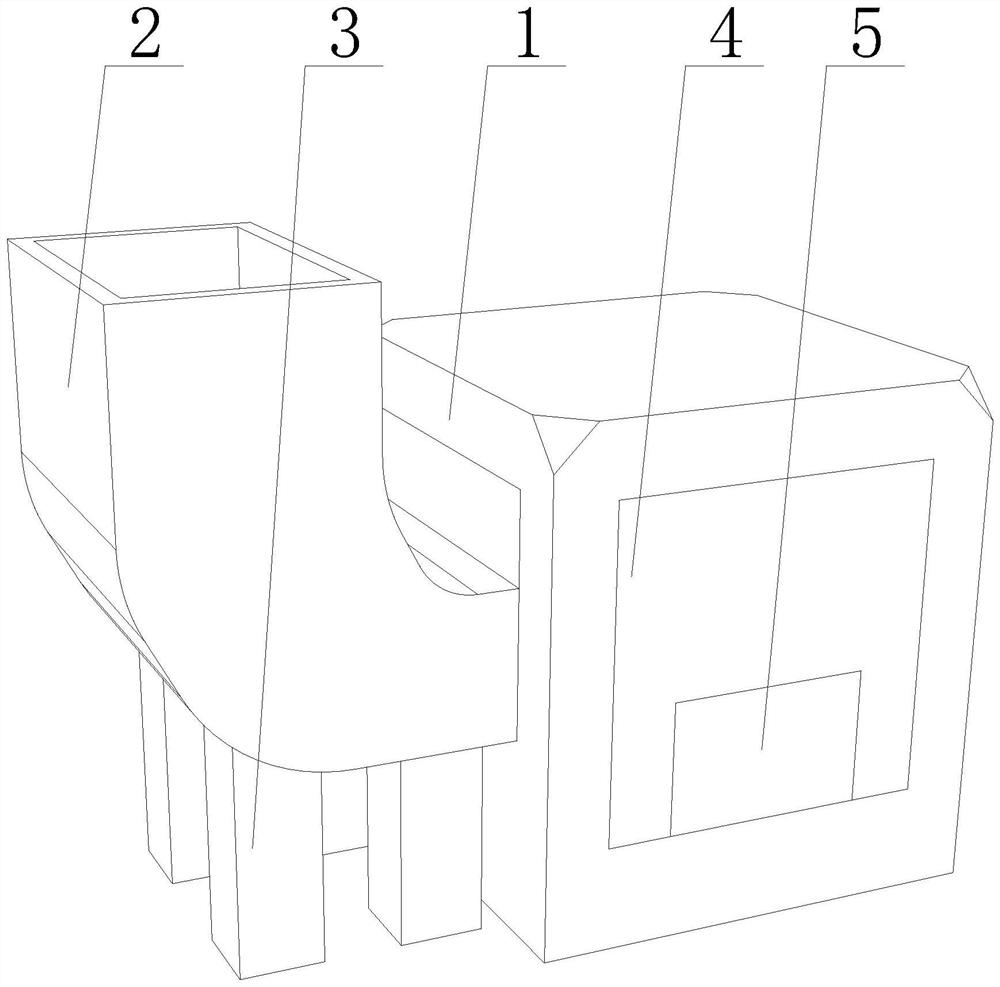

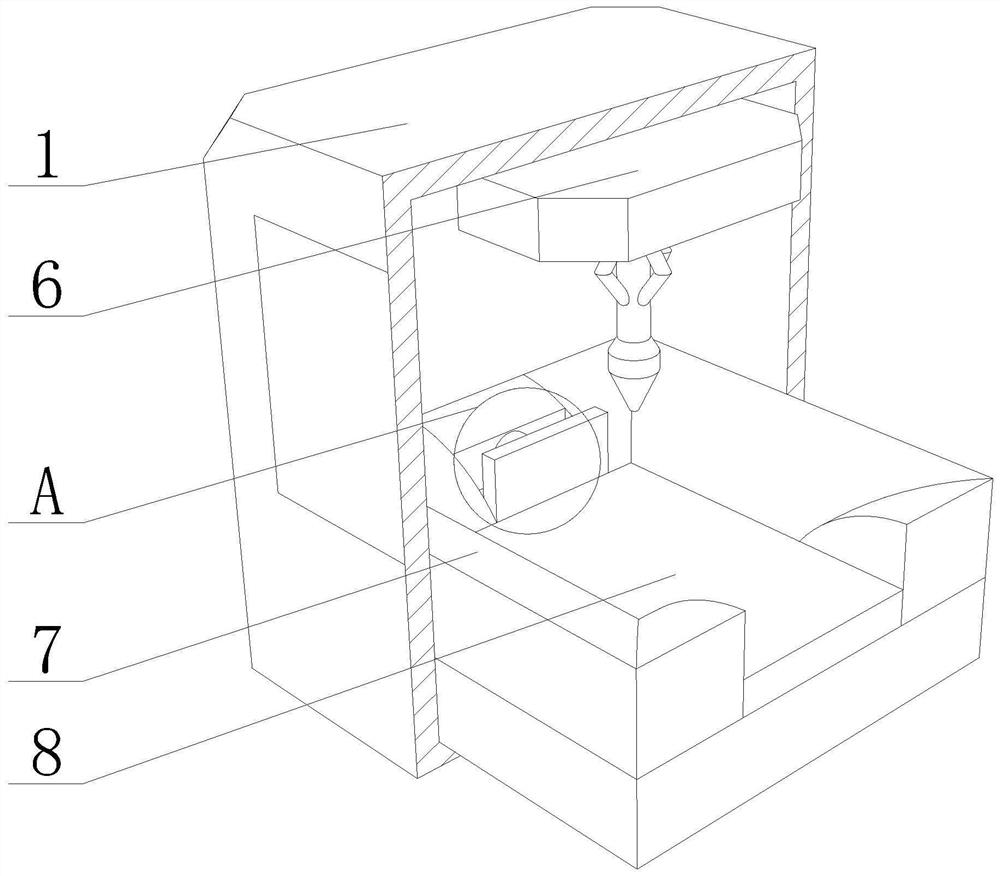

[0037] like figure 1 - Figure 7 As shown, the present invention provides a 3D printing device that can stably feed materials, including a printing device main body 1, a material conveying pipe 2, a pipe support frame 3, a transparent viewing mirror 4, a discharging sliding door 5, a printing main body 6 and a processing Plate 8, the left side of the printing device main body 1 is provided with a material conveying pipe 2, and the bottom of the material conveying pipe 2 is provided with a pipe support frame 3, the printing device main body 1 is electrically connected with an external power supply through a power cord, and the printing device main body 1 A transparent observation mirror 4 is arranged on the inner side of the device. The transparent observation mirror 4 enables the inside of the device to be observed in the outside world during operation. The inner side of the transparent observation mirror 4 is movably installed with a discharge sliding door 5. The top of the i...

Embodiment 2

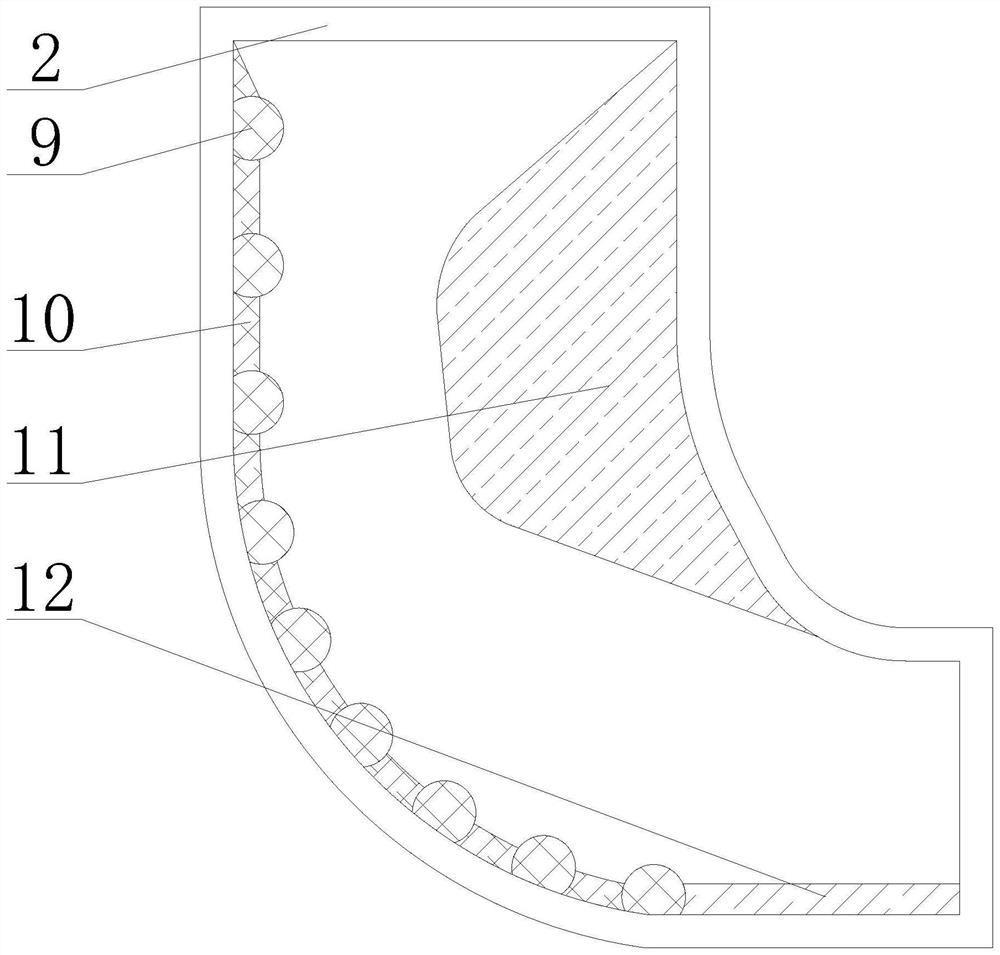

[0039] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a material inner guide plate 11 is provided on the right side of the inner wall of the material conveying pipe 2, and the right side of the material inner guide plate 11 is fixedly installed on the material conveying pipe 2. On the inner wall of the material conveying pipe 2, a material sliding table 12 is arranged on the inner wall of the material conveying pipe 2, and the bottom of the material sliding table 12 is fixedly installed on the inner wall of the material conveying pipe 2, and the material is placed in the material conveying pipe 2. 11. Make the material slide down onto the movable roller 9 and the connecting platform 10. By rotating the movable roller 9 inside the conveying pipe 2, the material slide table 12 can slide the material into the main body 1 of the printing device and guide it to the inner wall of the main body 1 of the printing device. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com