Shunting, transferring and conveying equipment for daily glass

A technology for conveying equipment and glass, which is applied in the direction of conveyor objects, transportation and packaging, lighting and heating equipment, etc., and can solve problems such as glass corners are easily broken, conveyor belt shunt transfer rate is low, transfer device volume and overall cost increase, etc. To achieve the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]In order to meet the diversion requirements of different grades and sizes of glass and the products that are inconsistent with the downstream glass secondary processing workshop, the glass not only moves on the conveyor line, but also requires the conveying equipment to be equipped with identification and diversion devices to judge Identify the grade, size and transportation direction of the glass, so that the entire glass diversion and transportation equipment is more intelligent. The mechanical device in the present invention is only used as the frame of the diversion and transportation of daily glass, and the centralized management and management of intelligent equipment and systems are also required. Participation requires staff to install and debug by themselves in the later stage;

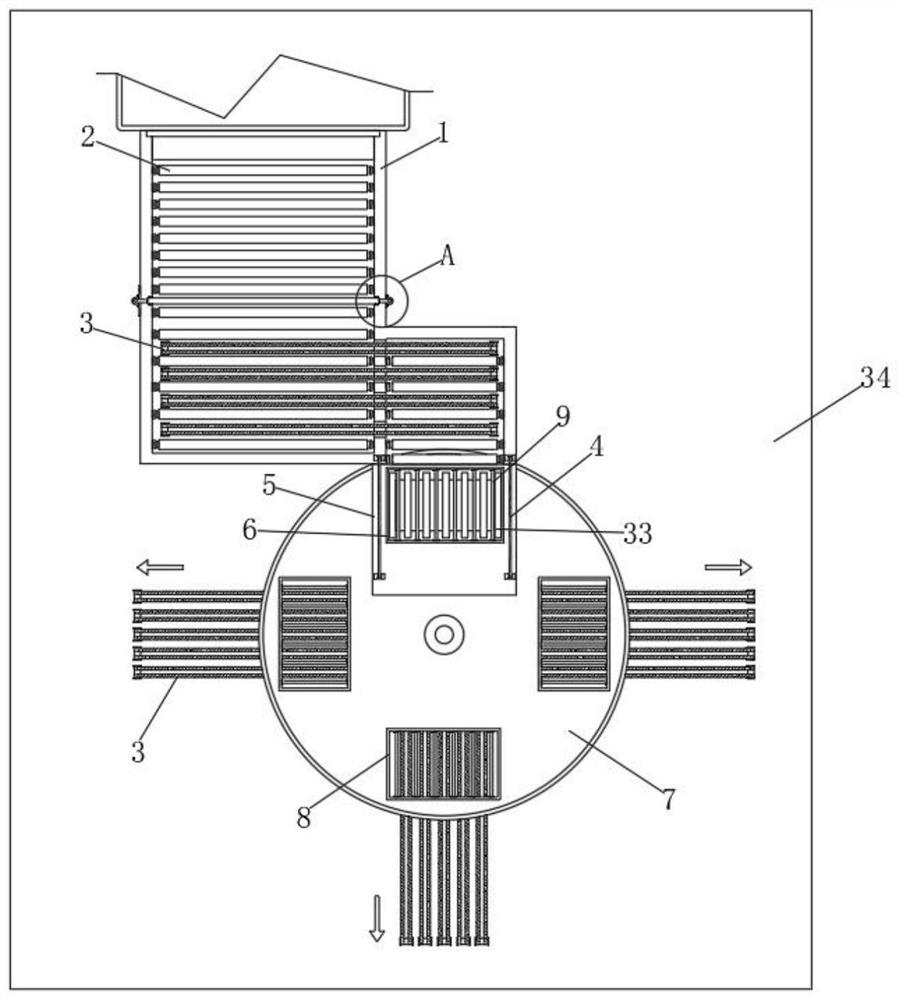

[0039] In the specific operation, after the preliminary processing of the entire glass is completed, the figure 1 On the rotating column 2 shown, the entire rotating column 2 is install...

Embodiment 2

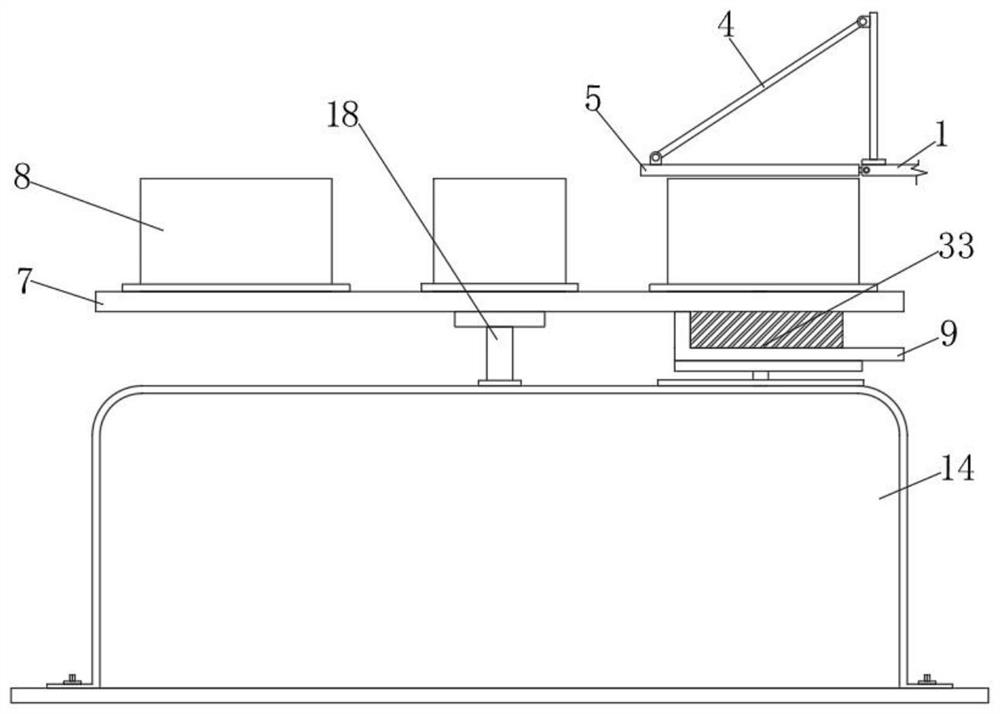

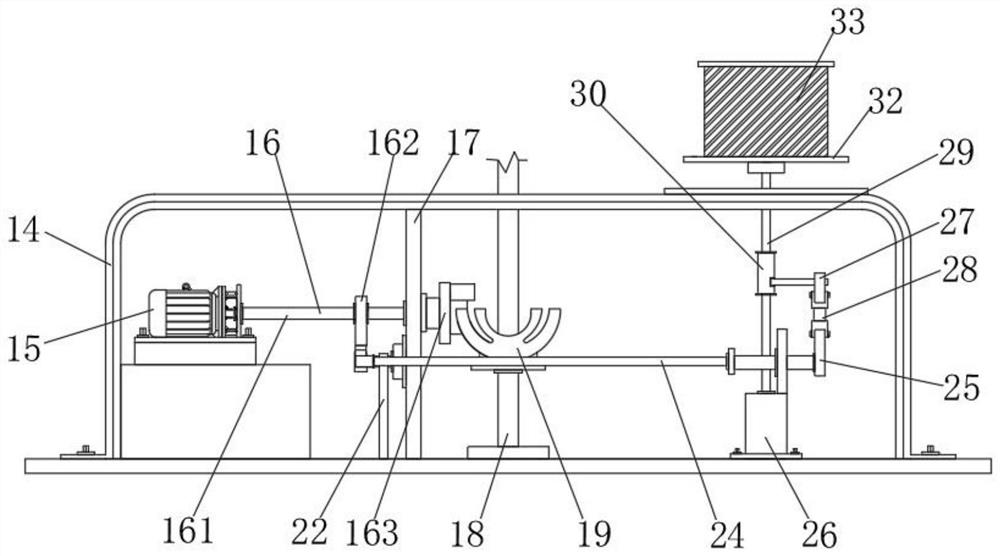

[0043] like Figure 2-3 As shown, the bottom of the entire temporary storage board 5 is installed with a box 14 and a turntable 7, the temporary storage board 5 is fixed on one side of the transmission fixing rod 1 through the connecting rod 4, and four temporary storage boxes 8 are installed on the entire turntable 7, The through slot 11 on the entire temporary storage box 8 is the same size as the discharge opening 6 opened on the temporary storage board 5, and at the same time, there are multiple sets of support rods 9 installed at the bottom of the entire temporary storage box 8. The shape of the entire temporary storage box 8 is as follows: Figure 4 As shown, a baffle plate 10 is installed on the support rod 9 near the outer side, and at the same time, the top of each support rod 9 is pasted with an anti-skid block 12 to prevent the glass from being subjected to centrifugal force during the rotation of the turntable 7 when the glass is placed on the support rod 9 The eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com