Continuous jumping and steering mechanism

A motion mechanism and body technology, which is applied in the field of quadruped support robot motion mechanism, can solve the problems of obstacle-surmounting ability and large range of motion, difficulty in realizing continuous jumping, and difficulty in controlling the jumping direction, and achieves easy jumping motion direction, simple structure, Easy-to-change effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

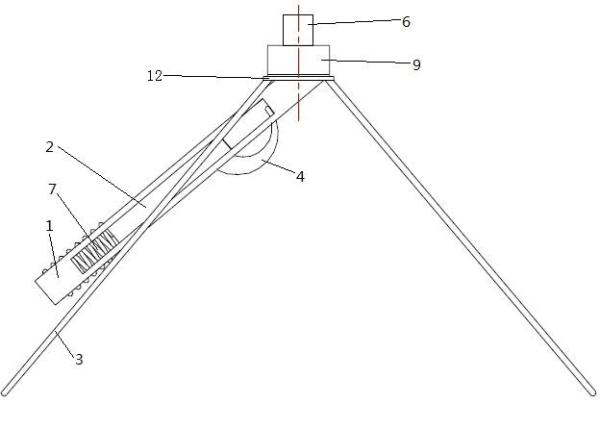

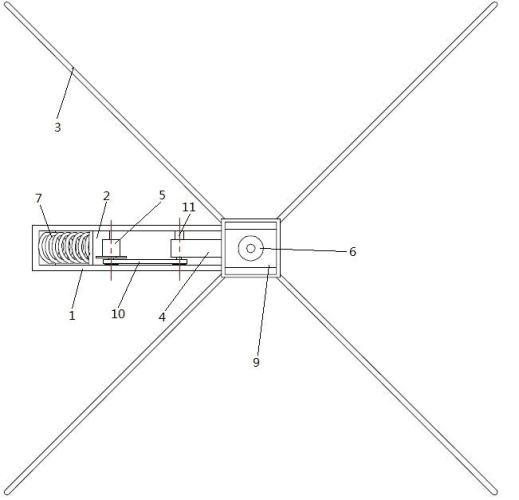

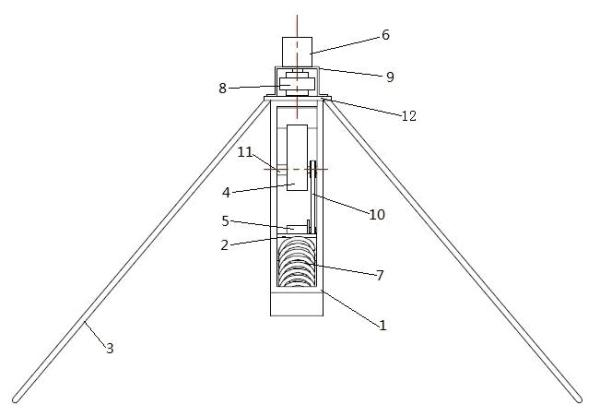

[0016] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures.

[0017] see Figure 1 to Figure 5 , the continuous jump and steering movement mechanism. It includes an inclined body, the top horizontal surface of the inclined body is connected with a rotating joint connected with the small holes in the center of the connecting plate at the top of the four supporting feet, and there is a chute in the inclined body, and a slider is installed in the chute; The driven shaft is fixed on the slider, a cam is installed on the driven shaft to form a cam mechanism, and a first motor is installed on the motor seat plate at the bottom of the slider; the output shaft of the motor and the driven shaft are driven by a synchronous belt; A secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com