Device for reducing growth of aluminum electrolysis shell head package

A shell head bag and aluminum electrolysis technology is applied in the field of devices for reducing the growth of the shell head bag, which can solve the problems of increasing the labor intensity of electrolyzers, frequent damage to the shell hammer head, etc., so as to achieve online repair, save time, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

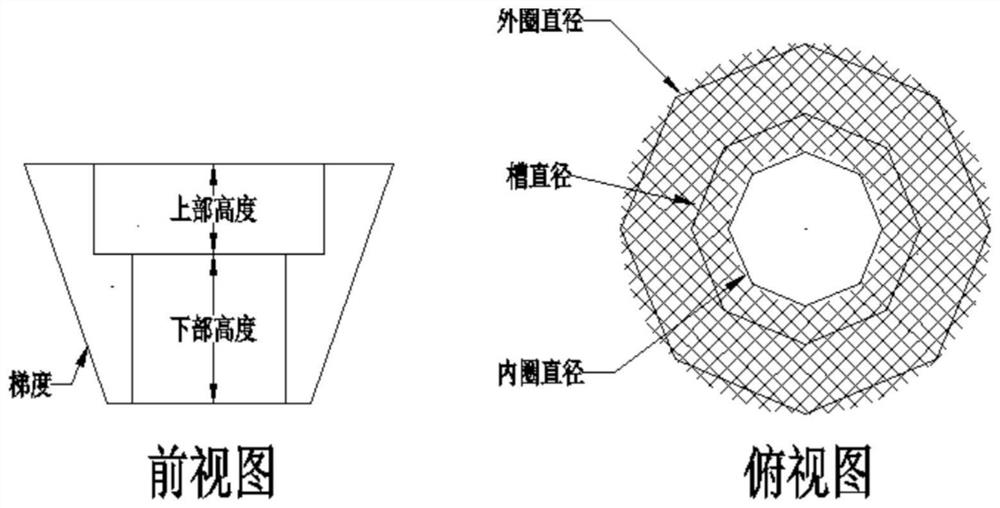

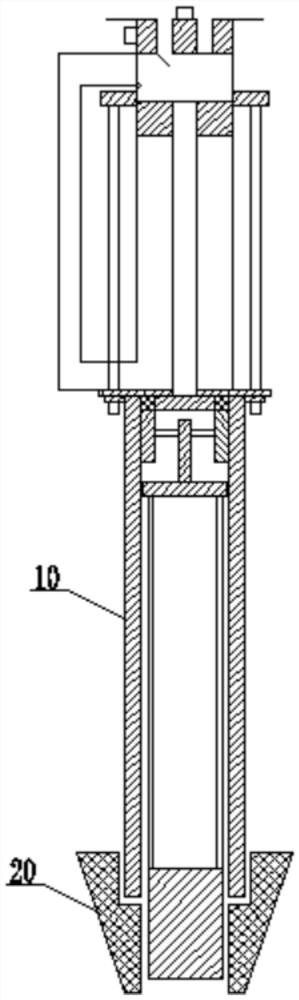

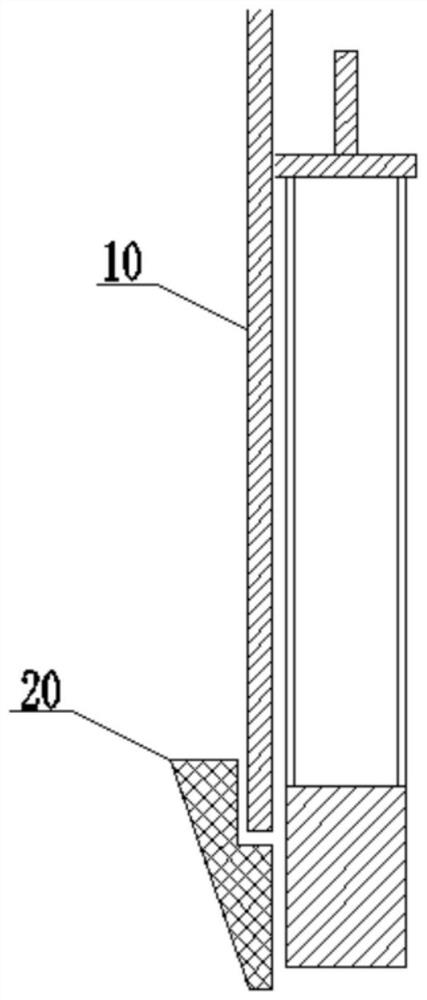

[0021] like Figure 1 to Figure 5 As shown, the device for reducing the growth of the aluminum electrolysis shell head bag of the present invention includes a protective sleeve 10, the protective sleeve 10 is arranged on both sides of the shell hammer, and the outer side of the bottom of the protective sleeve 10 is provided with an inverted conical protective sleeve 20. ; The protective sleeve 10 is fixed on the bottom of the cylinder wall by screws, and its structure is as follows figure 1 shown; the inverted conical sheath 20 is stuck on the outer side of the bottom of the protective sheath 10 through the arc-shaped inner wall, and its structure is as follows image 3 and Figure 4 shown.

[0022] In this embodiment, the diameter of the inner ring of the inverted conical sheath 20 is 50-55 mm.

[0023] In this embodiment, the diameter of the outer ring of the inverted conical sheath 20 is 60-65 mm.

[0024] In this embodiment, a groove is provided in the middle of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com