Automatic cleaning device for crust breaking of aluminum electrolysis cell

An automatic cleaning and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolytic cell shelling automatic cleaning device, can solve the problems of increasing the labor intensity of electrolyzers and frequent damage to shelling hammer heads, etc., and achieve online repair, save time, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

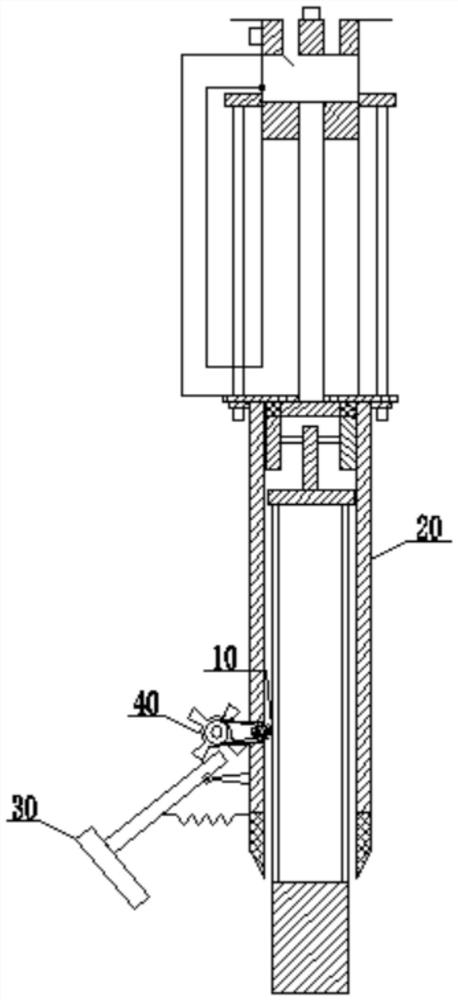

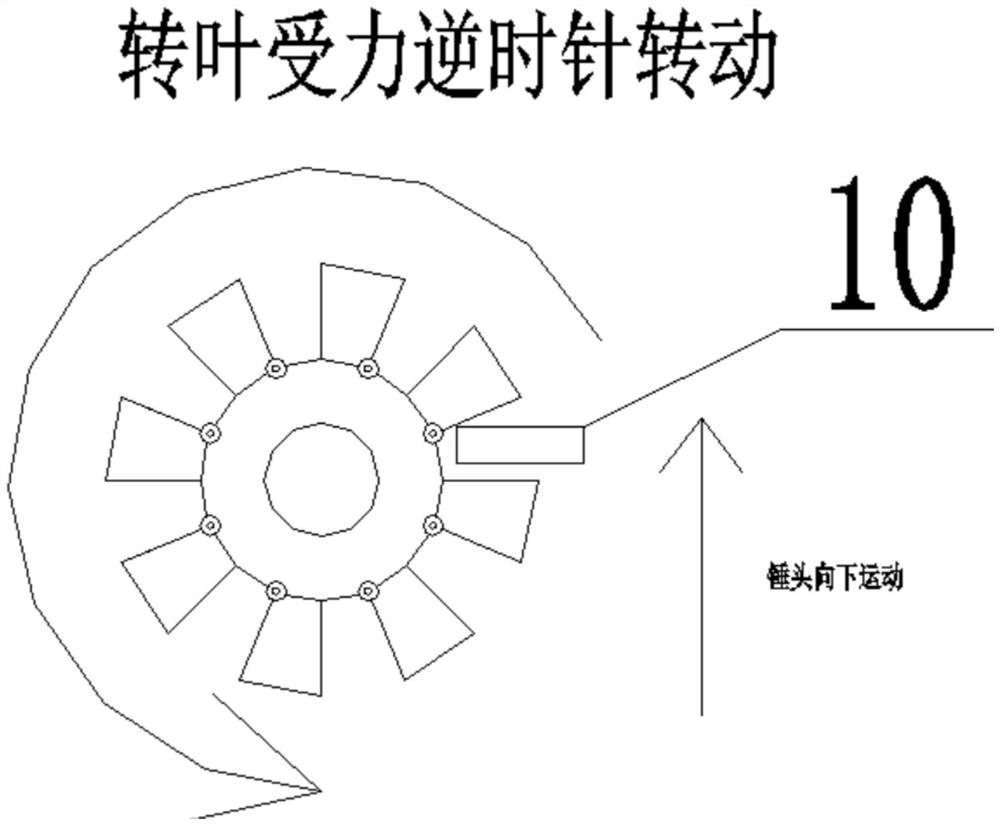

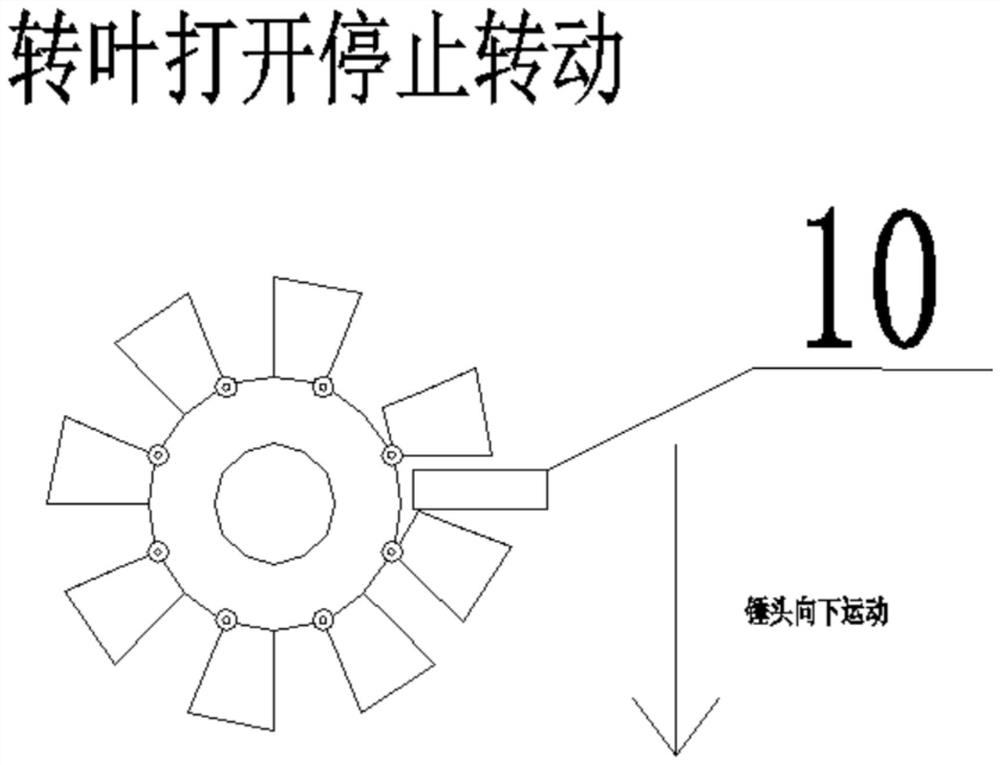

[0023] like Figure 1 to Figure 7 As shown, the aluminum electrolytic cell shelling automatic cleaning device of the present invention comprises a convex tooth 10, an installation fixing plate 20 and a cleaning hammer mechanism 30, the convex tooth 10 is fixed on the exposed part of the shelling hammer head, and the installation fixing plate 20 is installed in On the side of the shell hammer head, the cleaning hammer mechanism 30 is installed on the mounting and fixing plate 20 , and the protruding teeth 10 are connected with the cleaning hammer mechanism 30 through a gear linkage mechanism 40 .

[0024] In this embodiment, the gear linkage mechanism 40 includes a left gear 41, a right gear 42 and a linkage belt 43, the right gear 42 is connected with the convex teeth 10, the right gear 42 and the left gear 41 are connected to each other through the linkage belt 43, the left The gear 41 is connected with the cleaning hammer mechanism 30 .

[0025] In this embodiment, the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com