Mechanical crust breaking automatic cleaning device for aluminum electrolysis cell

A technology of automatic cleaning and aluminum electrolytic cell, applied in the field of shelling automatic cleaning device, which can solve the problems of increasing the labor intensity of electrolyzers, frequent damage of shelling hammer heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

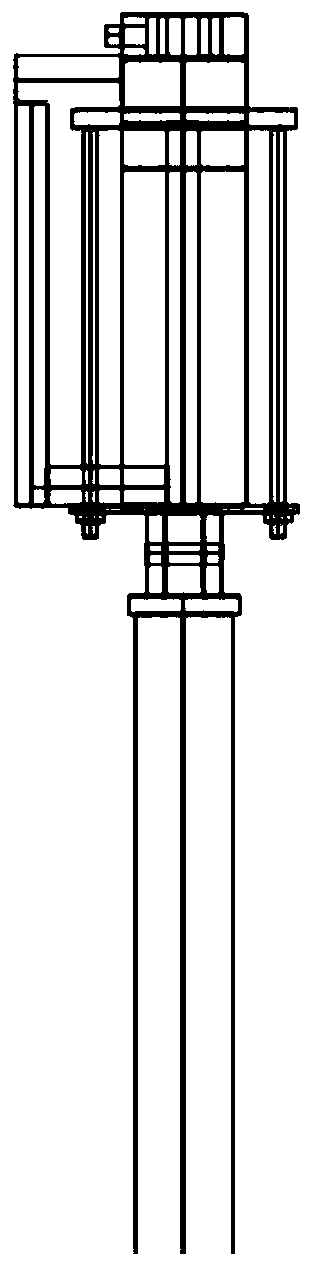

Image

Examples

Embodiment

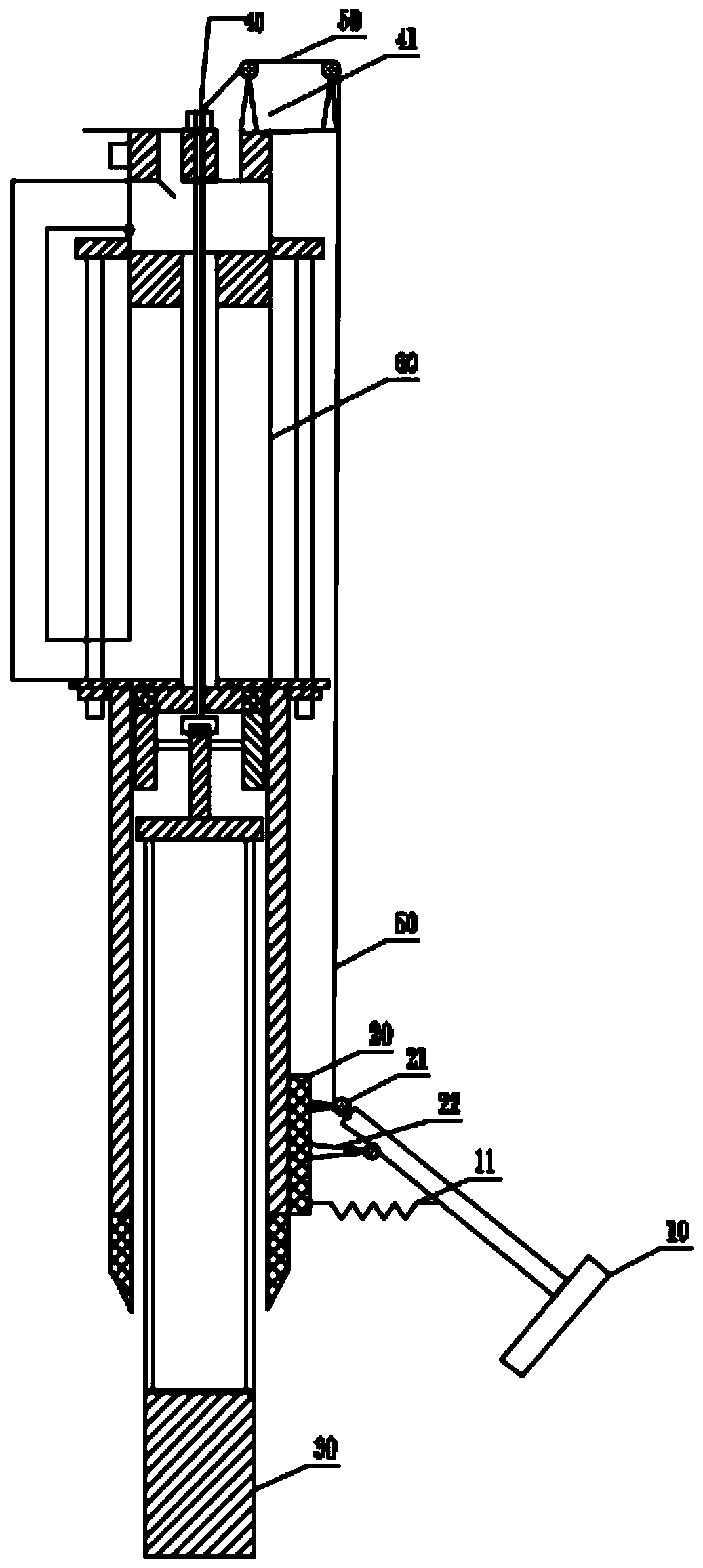

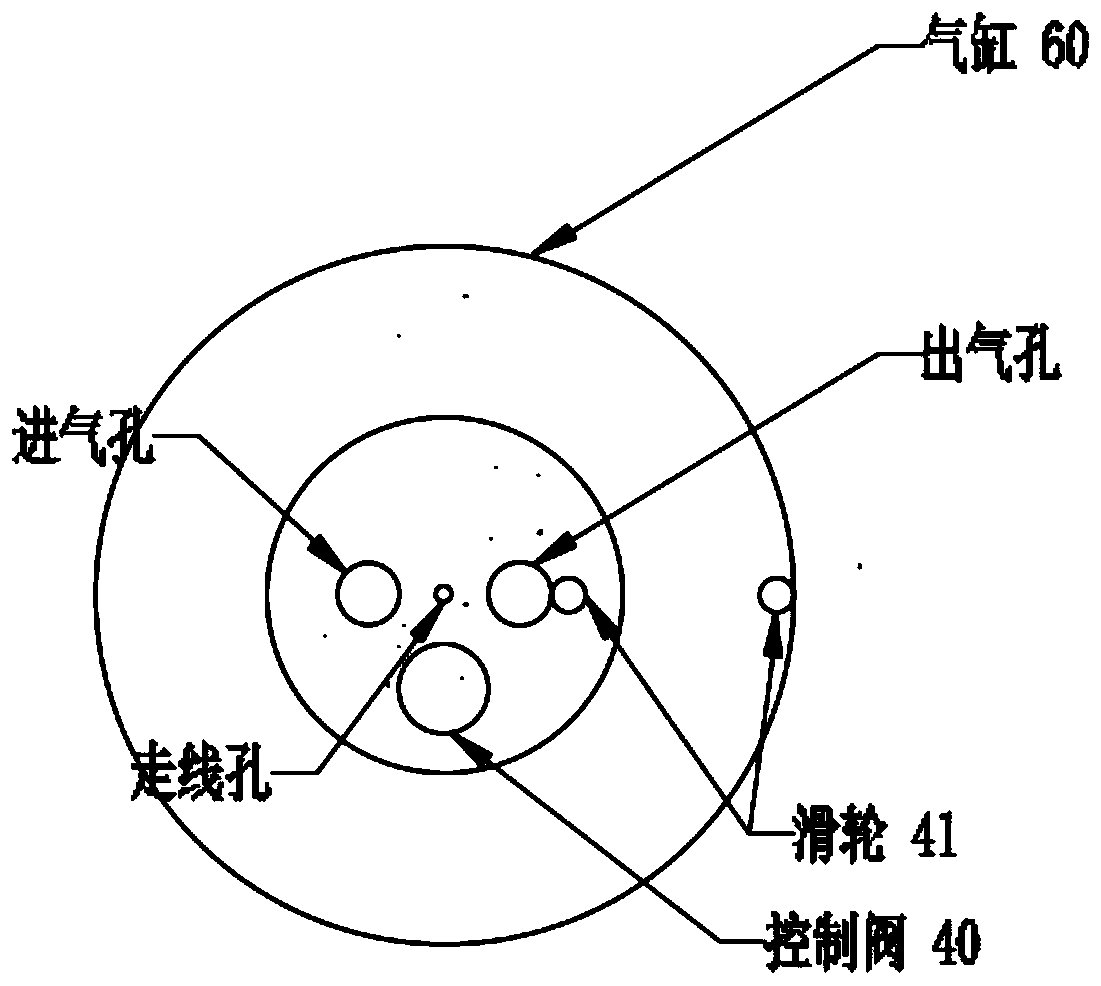

[0022] Such as Figure 2 to Figure 7 As shown, the aluminum electrolytic cell mechanical shelling automatic cleaning device of the present invention includes a cleaning hammer 10 and a protective plate 20, the protective plate 20 is arranged on one side of the shelling hammer head 30, and the rear end of the cleaning hammer 10 is rotatable and fixed On the protective plate 20, the cylinder valve head 40 is provided with a first static pulley 41, and the rear end of the protective plate 20 is provided with a second static pulley 21. The static pulley 41 and the second static pulley 21 are connected to the tail of the cleaning hammer 10 , and a return spring 11 is arranged between the front end of the cleaning hammer 10 and the protective plate 20 .

[0023] In this embodiment, a through hole is respectively arranged in the middle of the shelling cylinder 60 and the shelling valve head 40. The diameter of the through hole is 1 cm, and the through hole penetrates to the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com