Rotary automatic cleaning device for crust breaking of aluminum electrolysis cell

An aluminum electrolytic cell, automatic cleaning technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of increasing the labor intensity of electrolyzers, frequent damage to shelling hammers, etc., to achieve online repair, save time, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

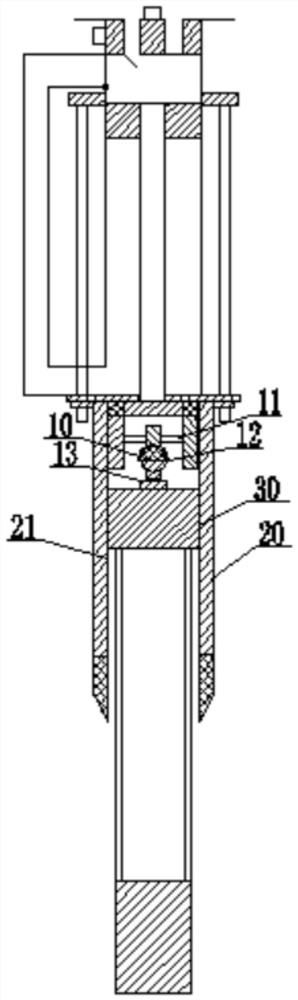

[0023] like Figure 1 to Figure 6 As shown, the rotary aluminum electrolytic cell shelling automatic cleaning device of the present invention includes a rotatable mechanism 10, and the rotatable mechanism 10 is arranged between the shelling hammer head and the fixed earring hole, and is arranged on the outside of the shelling hammer head. There is a cylindrical protective steel plate 20, and the cylindrical protective steel plate 20 is located on the lower side of the shelling cylinder, the inner side of the cylindrical protective steel plate 20 is provided with a helical guide rail 21, the outer side of the shelling hammer head is provided with a helical sleeve wire 30, the helical guide rail 21 and the spiral sleeve Wire 30 to match.

[0024] In this embodiment, the helical sleeve wire 30 is arranged on the outer side of the top of the shell hammer.

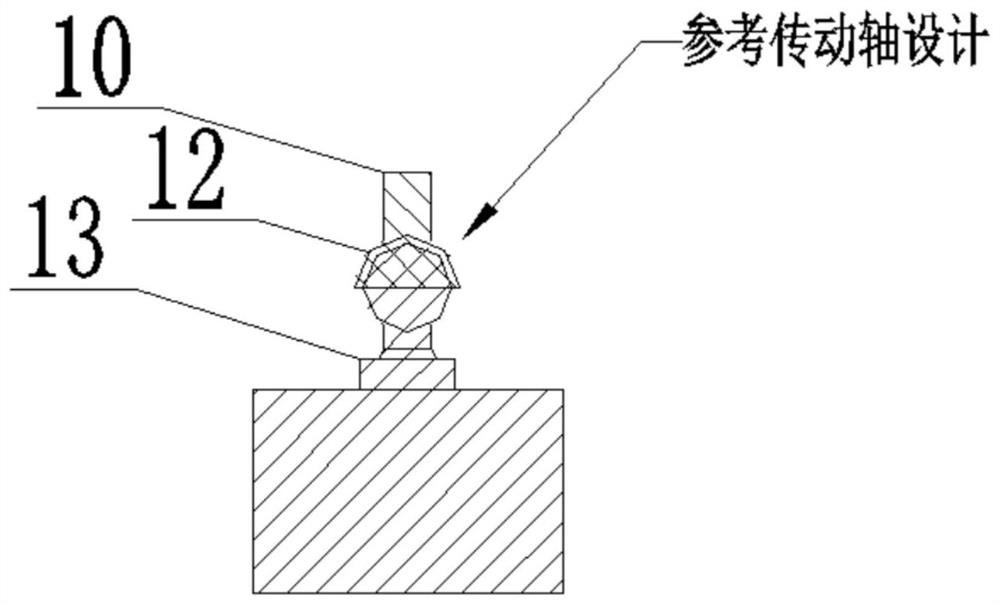

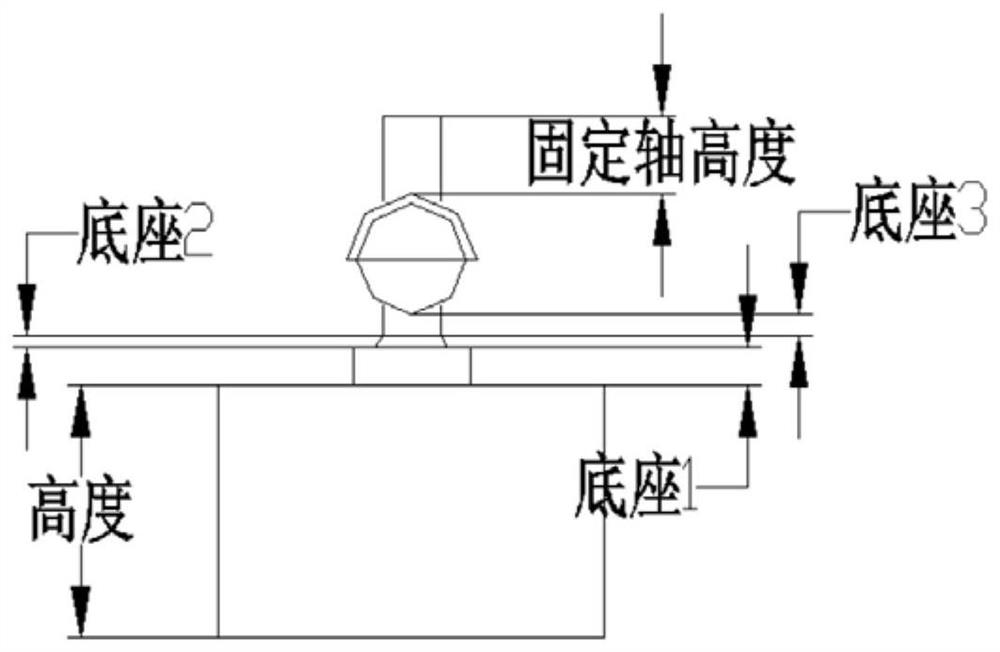

[0025] In this embodiment, the rotatable mechanism 10 includes a fixed shaft 11 , a spherical bearing 12 and a base 13 , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com