Automatic cleaning device for vibration crust breaking of aluminum electrolysis cell

A technology for automatic cleaning and aluminum electrolytic cells, applied in the field of automatic cleaning devices for shelling, can solve the problems of increasing the labor intensity of electrolyzers, frequent damage to shelling hammers, etc., and achieve the effect of online repair, time saving, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

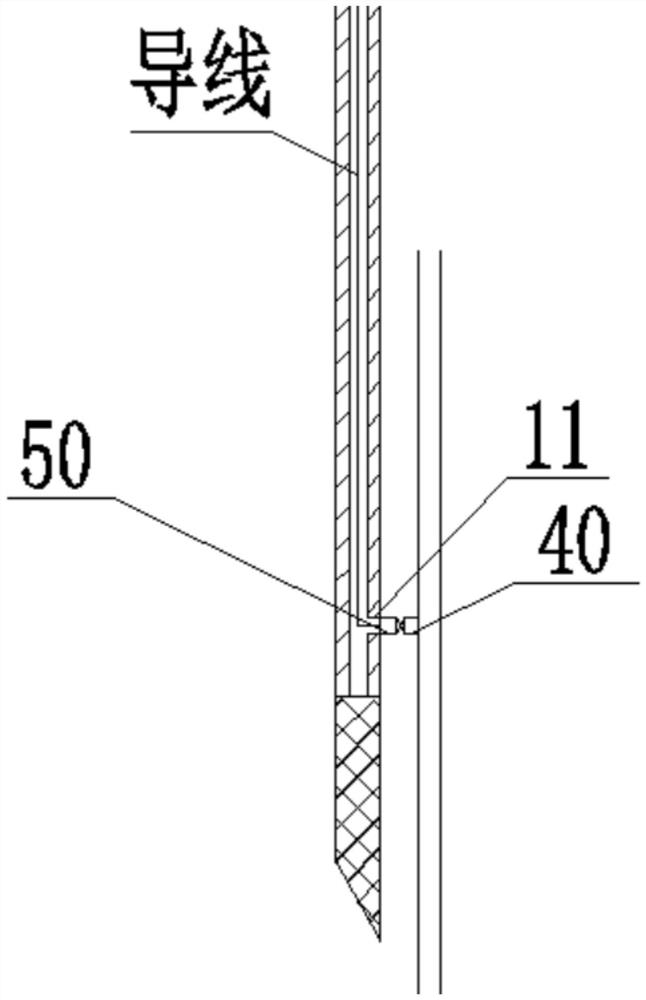

[0023] like Figure 1 to Figure 8 As shown, the aluminum electrolytic cell vibrating shell automatic cleaning device of the present invention includes a support platform 10, a metal support column 20 and a hollow protective wall 30, the support platform 10 is arranged in the upper middle part of the hollow hammer rod, and the metal support column 20 is arranged between the root of the hollow hammer head rod and the solid part of the hammer head, the hollow protective wall 30 is respectively arranged on the outer side of the upper part of the shell-beating hammer head, and a sliding contact point 40 is arranged on the outer side of the hollow rod of the hammer head, and the inner side of the hollow protective wall 30 is provided. Correspondingly, there are sliding contact points 50 , the sliding contact points 50 inside the hollow protective wall 30 are electrically connected to each other through wires, and the sliding contact points 40 outside the hollow rod of the hammer head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com