Post-cast strip turnover large-diameter steel pipe supporting device and using method thereof

A technology of steel pipe support and post-casting belt, which is applied to pillars, formwork/formwork/work frame, on-site preparation of building components, etc. Improved protection, enhanced high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

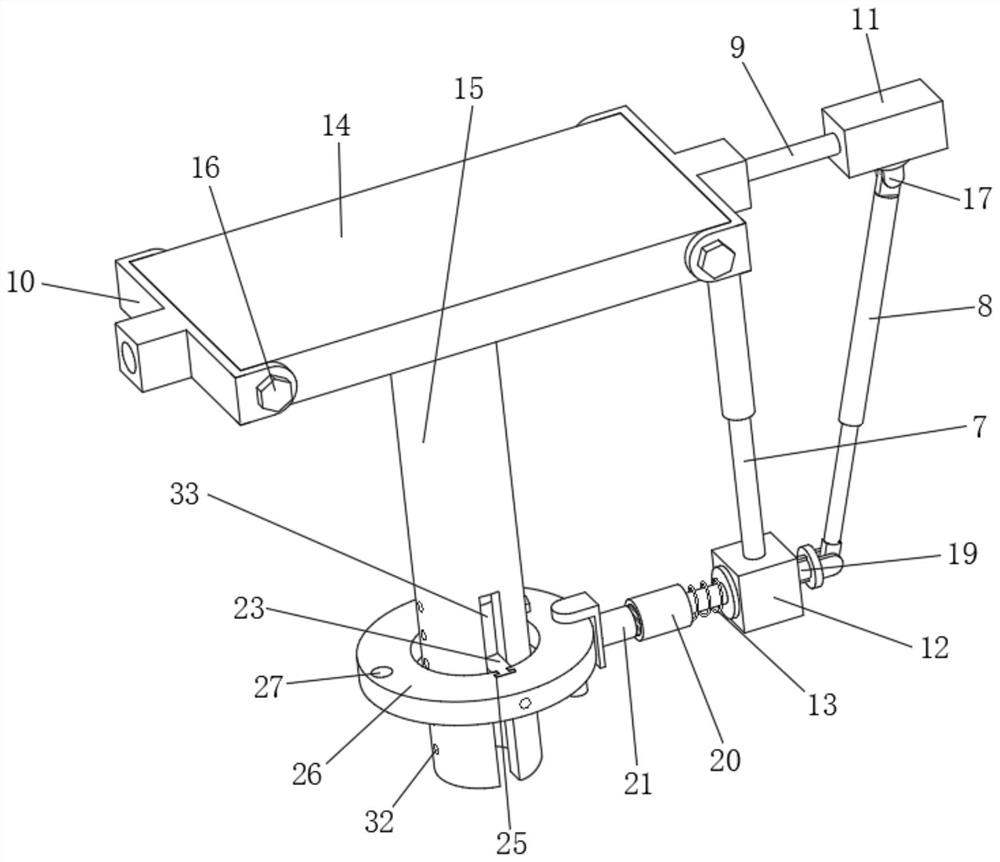

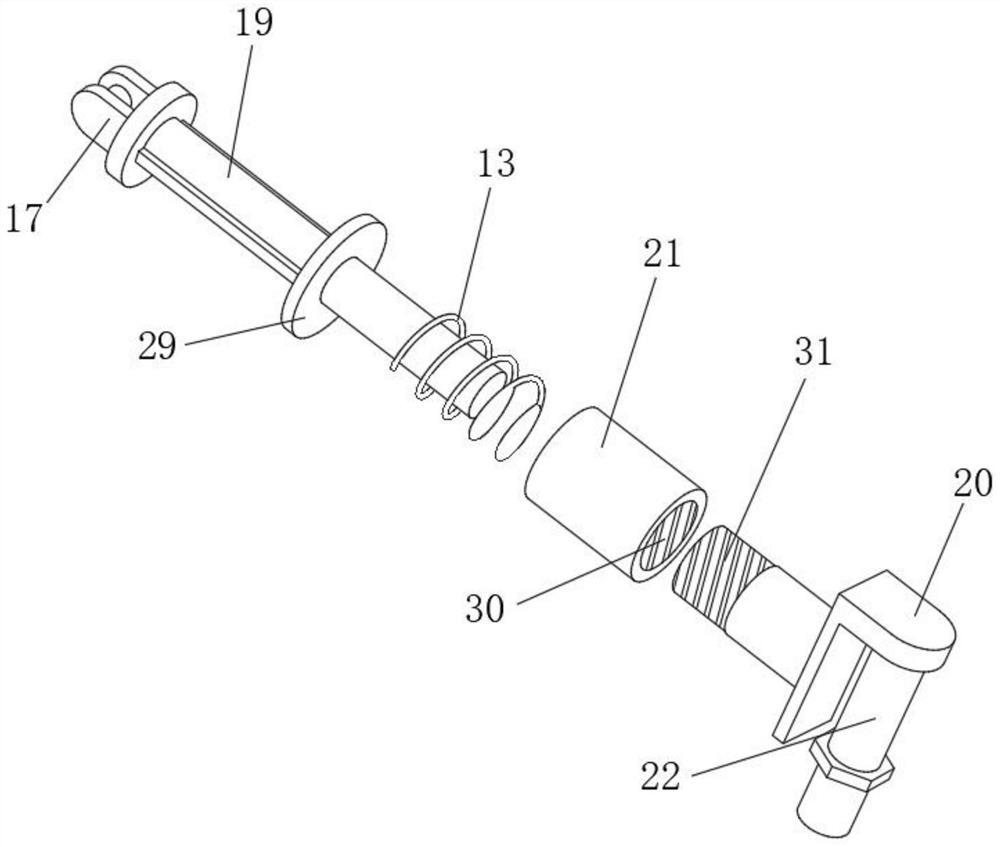

[0038] A post-casting belt can turn around a large-diameter steel pipe supporting device. The supporting device includes a post-casting belt assembly, a jack 3 and a supporting assembly.

[0039] The post-casting belt assembly includes a bottom plate 1, a pair of left-right symmetrical top plates 2 and a post-casting belt located in the gap between the adjacent top plates 2. Multiple groups of support assemblies arranged in a single row are arranged between the top plates 2 and the bottom plate 1. The support assemblies include The first steel pipe 4, the second steel pipe 6 and the jack 3, the first steel pipe 4 and the second steel pipe 6 are vertically connected and pressed on the bottom plate 1, the jack 3 is inserted on the second steel pipe 6, and the first steel pipe 4 and the second steel pipe 6 are vertically fixedly connected by the flange 5, and the vertical support assembly formed by the first steel pipe 4, the second steel pipe 6 and the jack 3 forms a vertical con...

Embodiment 2

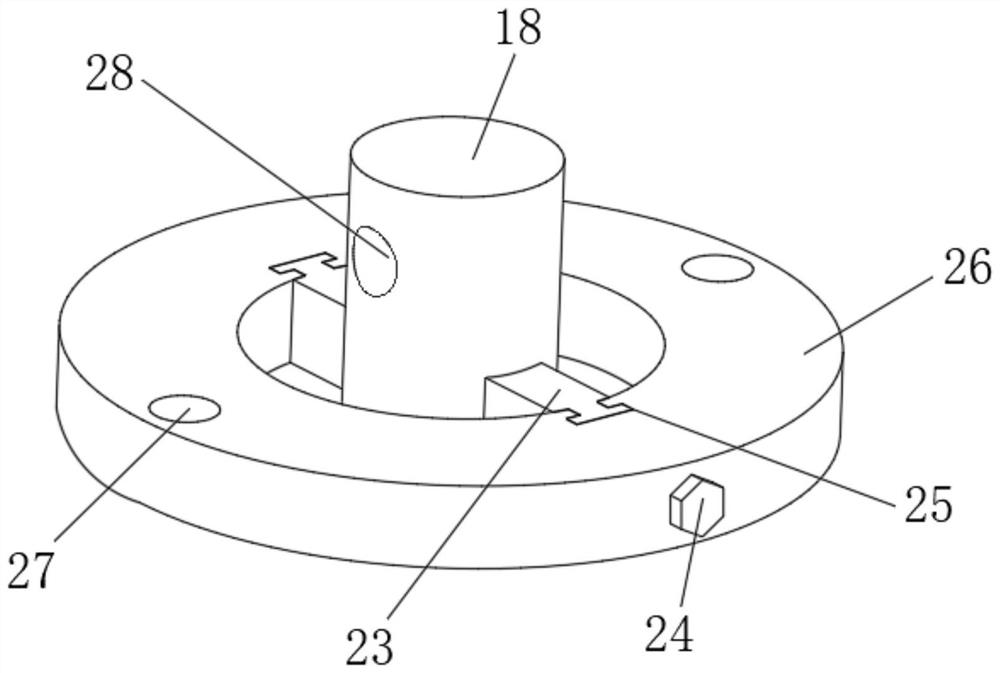

[0043]On the basis of Embodiment 1, in order to realize the fixed socket connection between the outer ring 26 and the inner column 18, the present application also has a gap between the inner wall of the outer ring 26 and the outer wall of the down tube 15, and the front and rear of the inner column 18 A pair of extension posts 23 are symmetrically arranged on both sides. The extension posts 23 extend to the outside of the lower tube 15 along the opening slot 33 . The inner wall of the outer ring 26 is provided with a T-shaped slot 25 corresponding to the opening slot 33 . Plugged into the T-shaped slot 25 , the extension column 23 and the outer ring 26 are fixedly connected by connecting bolts 24 .

[0044] Through the cooperation of the extension column 23 and the T-shaped slot 25, the limit socket connection between the outer ring 26 and the inner column 18 is realized, and the connection bolt 24 is used to realize the fixing, which is convenient for disassembly and installa...

Embodiment 3

[0046] On the basis of Embodiment 2, in order to improve the adaptation of the support device to the width of the post-casting belt, the present application also has a pair of side frames 10 symmetrically arranged on the left and right sides of the pallet 14, and the side frames 10 are fixed by fastening bolts 16. On the support plate 14 and the outer side of the side frame 10 is connected with the extension plate 9 through the cross bar 11 , and the extension plate 9 is attached to the lower end surface of the top plate 2 .

[0047] The support area is increased by the extension plate 9, and the adaptability to the width is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com