Cosmetic instrument air compressor overheating protection control method, system and equipment

An air compressor, overheating protection technology, applied in mechanical equipment, pump control, machine/engine, etc., can solve problems such as insufficient pressure, limited air compressor life, and high air compressor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

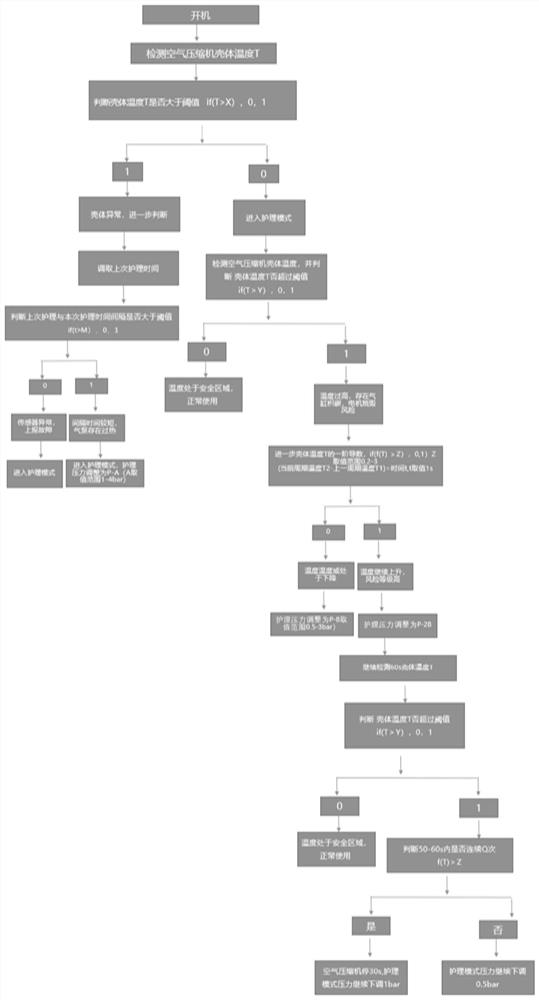

Image

Examples

Embodiment 1

[0050]1. Turn on the machine and detect the initial cylinder temperature T of the air compressor;

[0051] 2. Determine whether the initial temperature T is abnormal, that is, by setting the threshold X, the value of X is 40°C; when the temperature T exceeds 40°C, it is judged that the cylinder temperature is abnormal, and further testing is required; when the cylinder temperature is less than the threshold 40°C , the air compressor is in a normal state and can directly enter the nursing mode;

[0052] 3. When it is detected that the temperature T exceeds 40°C, further check whether the time interval between the last nursing time and this nursing is greater than the time threshold range M, and the value of M is 60mins. If the interval time is greater than 60mins, the theoretical heat dissipation of the air compressor is complete. It may be that the temperature sensor detects abnormality, then directly enter the nursing mode;

[0053] 4. If the detection time is less than 60mi...

Embodiment 2

[0055] 1. Turn on the machine and detect the initial cylinder temperature T of the air compressor;

[0056] 2. Determine whether the initial temperature T is abnormal, that is, by setting the threshold X, the value of X is 25°C; when the temperature T exceeds 25°C, it is judged that the cylinder temperature is abnormal, and further testing is required; when the cylinder temperature is less than the threshold 25°C , the air compressor is in a normal state and can directly enter the nursing mode;

[0057] 3. When it is detected that the temperature T exceeds 25 °C, further check whether the time interval between the last nursing time and this nursing is greater than the time threshold range M, and the value of M is 0.1min. Completely, it may be that the temperature sensor detects abnormality, then directly enter the nursing mode;

[0058] 4. If the detection time is less than 0.1min, the interval between two treatments may be short, and the overheating temperature of the air co...

Embodiment 3

[0060] 1. Turn on the machine and detect the initial cylinder temperature T of the air compressor;

[0061] 2. Determine whether the initial temperature T is abnormal, that is, by setting the threshold X, the value of X is 60°C; when the temperature T exceeds 60°C, it is judged that the cylinder temperature is abnormal, and further testing is required; when the cylinder temperature is less than the threshold 60°C , the air compressor is in a normal state and can directly enter the nursing mode;

[0062] 3. When it is detected that the temperature T exceeds 60°C, further check whether the time interval between the last nursing time and the current nursing is greater than the time threshold range M, and the value of M is 120mins. If the interval time is greater than 120mins, the theoretical heat dissipation of the air compressor is complete. It may be that the temperature sensor detects abnormality, then directly enter the nursing mode;

[0063] 4. If the detection time is less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com