Calibration board, calibration method and calibration system

A calibration method and calibration board technology, applied in image analysis, instruments, calculations, etc., can solve problems such as calibration parameter errors, increase in total imaging distortion, imaging distortion, etc., to meet calibration requirements, improve calibration accuracy, and avoid uncertain variables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

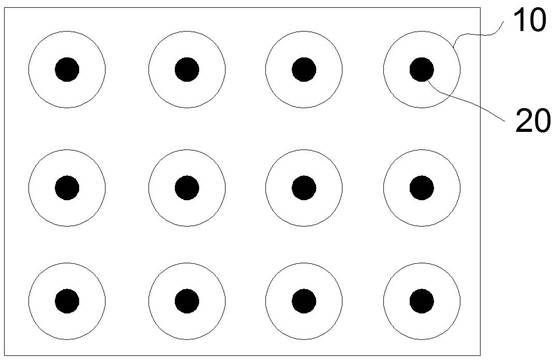

[0043] like figure 2 As shown, a calibration plate includes a two-dimensional plane on which a plurality of hollow calibration patterns 10 are distributed, and each hollow calibration pattern 10 is provided with a corresponding solid calibration pattern 20, wherein a plurality of The hollow calibration patterns 10 are distributed in M rows and N columns on the two-dimensional plane, where M, N≥2.

[0044] The color of the hollow calibration pattern 10 and the corresponding solid calibration pattern 20 is not limited, and can be black; the hollow calibration pattern 10 is a hollow circle, the solid calibration pattern 20 is a solid circle, and the center of mass of each solid circle 20 corresponds to The center of the hollow circle 10.

Embodiment 2

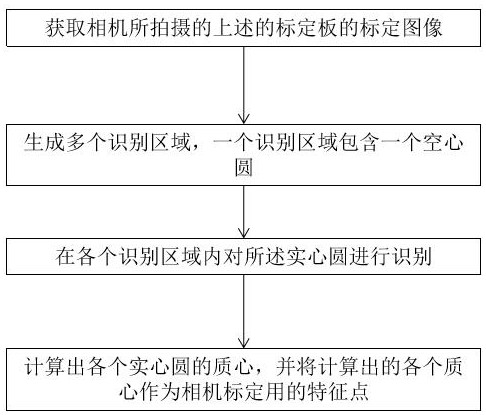

[0046] like image 3As shown, a calibration method includes the following steps:

[0047] S1: Acquire the calibration image of the calibration plate captured by the camera.

[0048] In this step S1, as figure 2 As shown, the calibration plate includes a two-dimensional plane on which a plurality of hollow calibration patterns 10 are distributed, and each hollow calibration pattern 10 is provided with a corresponding solid calibration pattern 20, wherein a plurality of hollow calibration patterns 10 are provided. The calibration patterns 10 are distributed in M rows and N columns on the two-dimensional plane, where M and N≥2.

[0049] The color of the hollow calibration pattern 10 and the corresponding solid calibration pattern 20 is not limited, and can be black; the hollow calibration pattern 10 is a hollow circle, the solid calibration pattern 20 is a solid circle, and the center of mass of each solid circle 20 corresponds to The center of the hollow circle 10.

[005...

Embodiment 3

[0085] A calibration system, comprising a calibration board and a calibration device, the calibration board is used to communicate with a camera, so as to drive the camera to shoot at the calibration board, and receive a calibration image captured by the camera to perform embodiments The calibration method described in 2.

[0086] like figure 2 As shown, the calibration plate includes a two-dimensional plane on which a plurality of hollow calibration patterns 10 are distributed, and each hollow calibration pattern 10 is provided with a corresponding solid calibration pattern 20, wherein a plurality of hollow calibration patterns 10 are provided. The calibration patterns 10 are distributed in M rows and N columns on the two-dimensional plane, where M and N≥2.

[0087] The color of the hollow calibration pattern 10 and the corresponding solid calibration pattern 20 is not limited, and can be black; the hollow calibration pattern 10 is a hollow circle, the solid calibration p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com